Method for coating motor vehicle exhaust cleaning catalyst

A tail gas purification and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of high cost, complicated process, difficult to use catalyst coating, etc., to achieve low price and easy operation Simple, the effect of reducing the amount of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This example takes the preparation of a single platinum catalyst as an example to illustrate the method for preparing a noble metal catalyst disclosed in the present invention.

[0062] (1) Carrier pretreatment

[0063] The carrier is a wall-flow wall-flow cordierite honeycomb ceramic carrier, purchased from Yixing Prince Pottery Co., Ltd., Φ127×118mm, 200 mesh, crushed, take a 2cm square piece and soak the carrier with 5% nitric acid for 24 hours, and use pure Wash with water, and bake at 90°C for 10 hours. stand-by.

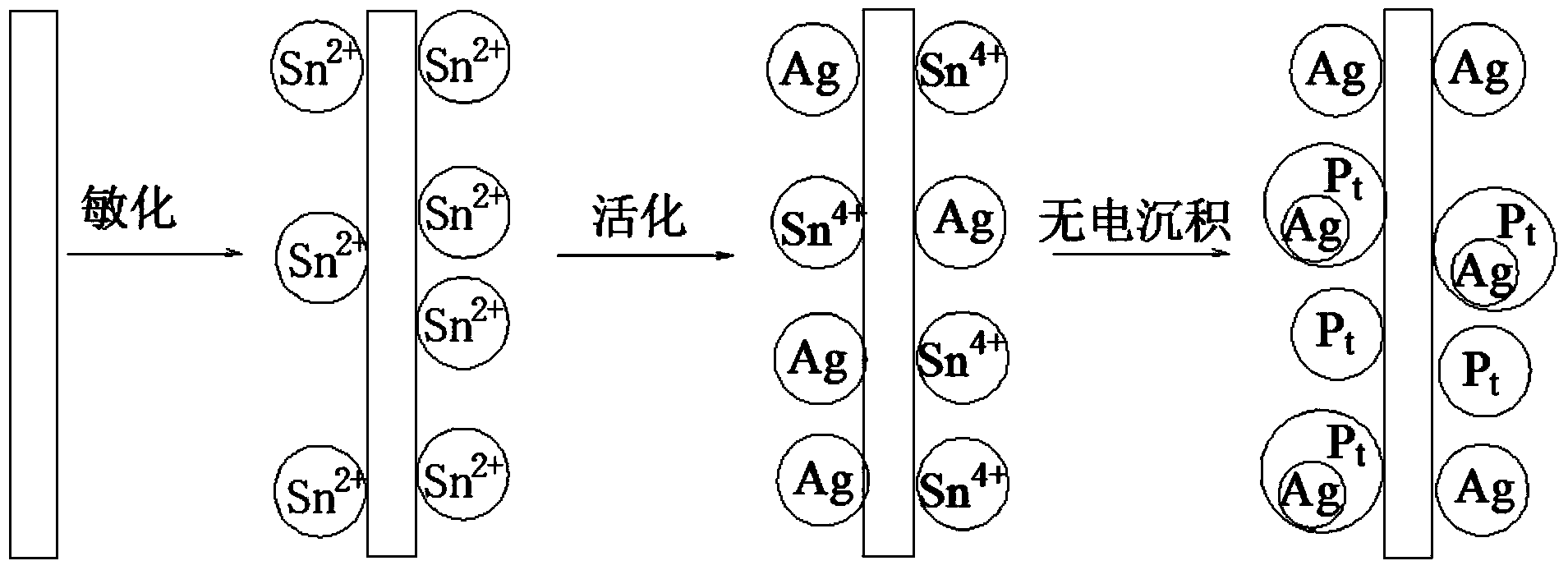

[0064] (2) Carrier sensitization

[0065] Put the carrier treated in step (1) into the sensitization solution, stay for 60min, prepare 250ml sensitization solution, the solvent of the sensitization solution is deionized water and CH at a volume ratio of 1:1 3 OH, the solute is SnCl 2 and C 2 HF 3 o 2 , SnCl 2 The concentration is 22mmol / L, C 2 HF 3 o 2 The concentration is 70mmol / L.

[0066] (3) Carrier activation

[0067] Take out the sensi...

Embodiment 2

[0076] (1) Carrier pretreatment

[0077] The carrier is a wall-flow honeycomb ceramic, which is soaked in 30% nitric acid for 24 hours, washed with pure water, and baked at 120° C. for 10 hours.

[0078] (2) Carrier sensitization

[0079] Put the carrier processed in step (1) into the sensitization solution and stay for 90min. The solvent of the sensitization solution is deionized water and CH at a volume ratio of 1:1. 3 OH, the solute is SnCl 2 and C 2 HF 3 o 2 , SnCl 2 The concentration is 27mmol / L, C 2 HF 3 o 2 The concentration is 80mmol / L.

[0080] (3) Carrier activation

[0081] Take out the sensitized carrier in step (2), rinse it with methanol first, then rinse it with pure water, and then immerse it in the activation solution for 30 minutes. The activation solution is AgNO 3 Dissolve in pure water to make a 40mmol / L solution, and then titrate with 37% ammonia water until the brown silver oxide precipitate disappears, thus obtaining the activation solution. ...

Embodiment 3

[0090] (1) Carrier pretreatment

[0091] The carrier is straight-through honeycomb ceramics, soaked in 5% nitric acid for 24 hours, washed with pure water, and baked at 90°C for 10 hours.

[0092] (2) Carrier sensitization

[0093] Put the carrier processed in step (1) into the sensitization solution and stay for 30min. The solvent of the sensitization solution is deionized water and CH at a volume ratio of 1:1. 3 OH, the solute is SnCl 2 and C 2 HF 3 o 2 , SnCl 2 The concentration is 17mmol / L, C 2 HF 3 o 2 The concentration is 60mmol / L.

[0094] (3) Carrier activation

[0095] Take out the sensitized carrier in step (2), rinse it with methanol first, then rinse it with pure water, and then immerse it in the activation solution and stay for 20 minutes. The activation solution is AgNO 3 Dissolve in pure water to form a 30mmol / L solution, and then titrate with 37% ammonia water until the brown silver oxide precipitate disappears to obtain the activation solution.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com