Method for improving phospholipase D transesterification activity and method for producing phosphatidylserine by using phospholipase D transesterification activity

A technology of phosphatidylserine and phospholipase, applied in the direction of biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve problems such as neglect, and achieve the effect of simple and easy operation, low production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

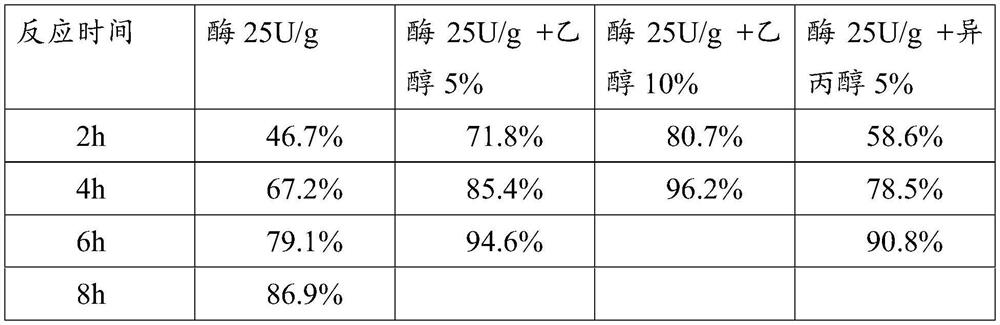

[0021] Comparative experiment of translipid activity

[0022] Add 100g of soybean lecithin with a phosphatidylcholine content of 58.6%, 200g of L-serine, and 20g of calcium chloride in 1L of pure water. Put into a constant temperature water bath at 42°C, stir at 300rpm, add 125uL phospholipase D (25U / g) to each group, and add 12.5mL ethanol (5% of water volume) and 25mL ethanol (5% of water volume) to groups 2-4, respectively. 10%), 12.5mL isopropanol (5% of water volume), use high performance liquid chromatography to monitor the conversion rate of PC→PS, the conversion rate measurement result after reaction carries out 2h, 4h, 6h and 8h is shown in the table below.

[0023]

[0024]

Embodiment 2

[0026] Enzyme-catalyzed production of phosphatidylserine

[0027] In 1L of pure water, add 100g soybean phospholipid with a phosphatidylcholine content of 53.6%, 200g L-serine, 20g calcium chloride, stir at 500rpm and heat up to 39-43°C, add 0.5mL phospholipase D (25U / g ), the conversion rates of PC→PS detected after 2h, 4h, and 6h were 50.9%, 77.9%, and 87.1%, respectively.

Embodiment 3

[0029] Enzyme-catalyzed production of phosphatidylserine

[0030] Add 100g phosphatidylcholine content in 1L pure water and be 53.6% soybean lecithin, 200g L-serine, 20g calcium chloride, 500rpm stir well and be warmed up to 39-43 ℃, add 50mL ethanol, 0.5mL phospholipase D ( 25U / g), the conversion rates of PC→PS were detected at 2h, 4h, and 6h to be 71.0%, 90.5%, and 94.4%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com