Rare-earth catalytic oxidation device and method for printing and dyeing wastewater

A rare earth catalysis and oxidation treatment technology, which is applied in textile industry wastewater treatment, oxidized water/sewage treatment, multi-stage water treatment, etc., can solve the problem of high operating costs and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

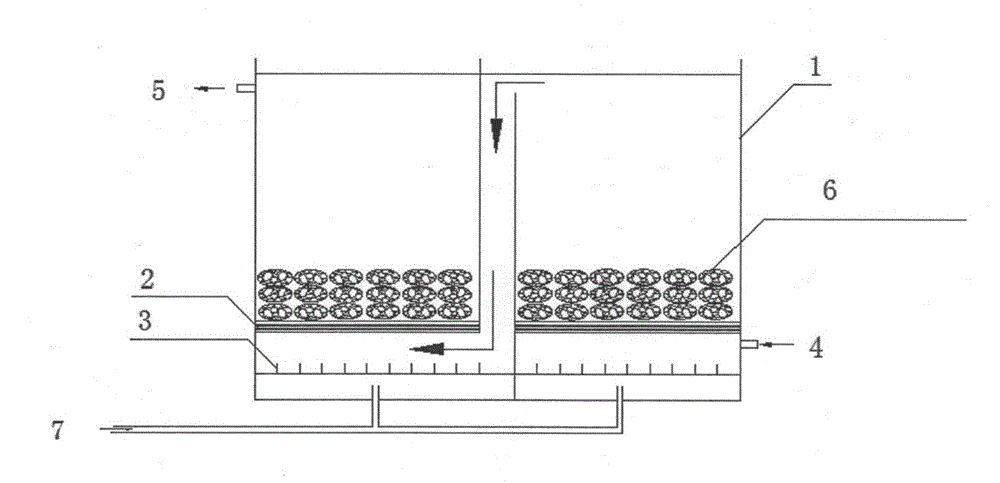

[0024] Such as figure 1 Shown is a schematic diagram of a rare earth catalytic oxidation treatment device for printing and dyeing wastewater. The rare earth catalytic oxidation treatment device for printing and dyeing wastewater includes a reaction tank 1 in which a grid partition 2 and a grid partition 2 are provided. The lower aeration device 3 includes a polyethylene tube aeration rod with an outer diameter of 10 cm, an inner diameter of 6 cm, and an average pore diameter of 0.05 μm, and compressed air 7 is passed into the aeration device for aeration. The grid partition 2 is provided with a catalytic oxidation reaction bag; the side wall of the reaction tank 1 is provided with a water inlet 4 and a water outlet 5, and the water inlet 4 is located in the aeration device 3 and the grid partition 2 In between, the water outlet 5 is located above the catalytic oxidation reaction bag; the preparation method of the catalytic oxidation reaction bag is: take waste residue from a ra...

Embodiment 2

[0026] A printing and dyeing factory specializes in the production of export curtain fabrics. The pre-treatment and refining wastewater accounts for 8% of the total drainage. The average COD concentration is 10000mg / L, alkaline, pH 13-14, no need to adjust the pH value, directly input from the water inlet of Example 1 The aeration treatment is carried out in the rare earth catalytic oxidation treatment device for printing and dyeing wastewater, the aeration ratio is 20:1, the aeration reaction is 4h, and the volume ratio of mixed rare earth-iron-carbon catalytic oxidant and wastewater is 1:4. After the end, the pH automatically tends to 9-11, remove the printing and dyeing wastewater rare earth catalytic oxidation treatment device to another reaction tank, add XSD-1 accelerator (Shanghai Xisun Environmental Technology Co., Ltd.) 0.030wt%, aeration for 1 hour, use ordinary The coagulant separation of 100ppm basic aluminum chloride and 1ppm of anionic PAM coagulant can achieve COD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com