Method for synthesizing and purifying high-purity fatty acyl monoglyceride

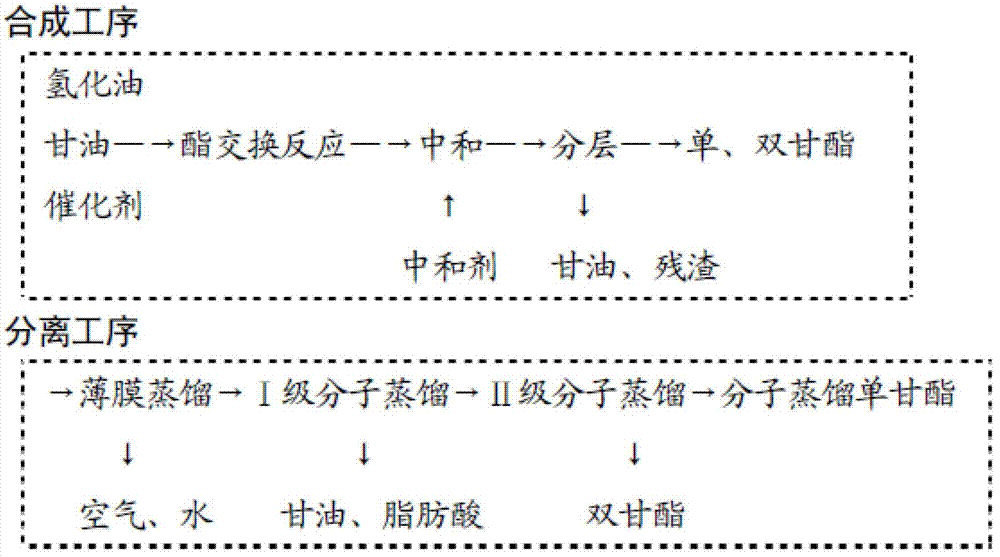

A fatty acyl monoglyceride and fatty acyl monoglyceride technology, which is applied in the field of food emulsifier preparation, can solve the problems of excessive glycerol and glyceride, which cannot be layered, long reaction time, and saponification side reactions, and saves equipment investment and reaction. The effect of fast speed and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

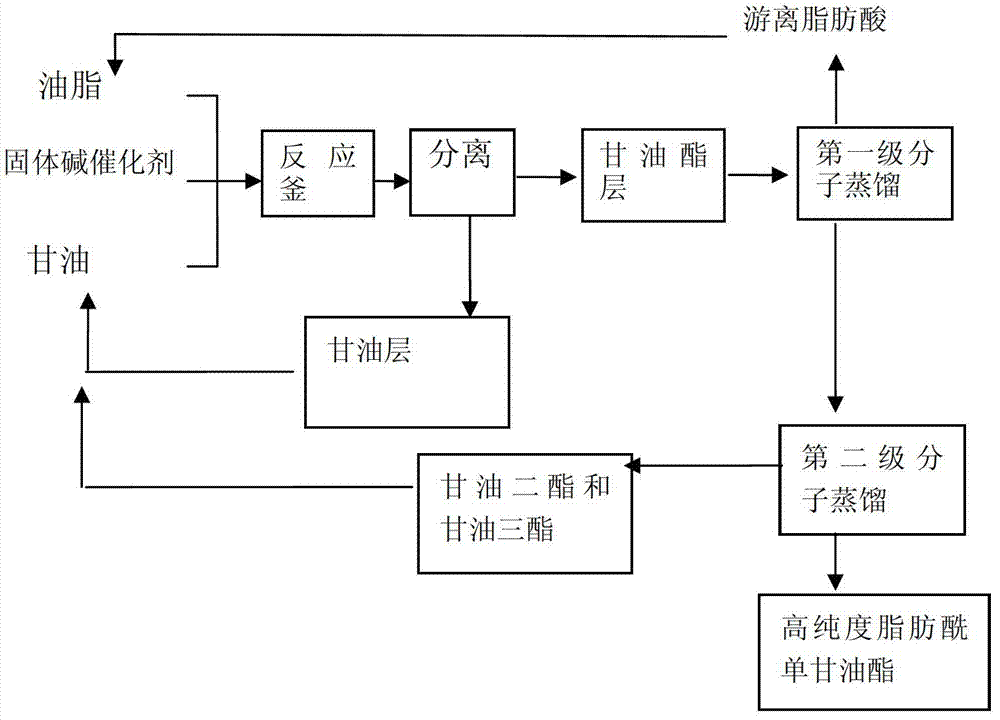

[0030] The synthesis and purification process diagram of high-purity fatty acyl monoglyceride in this embodiment is as follows figure 2 Shown:

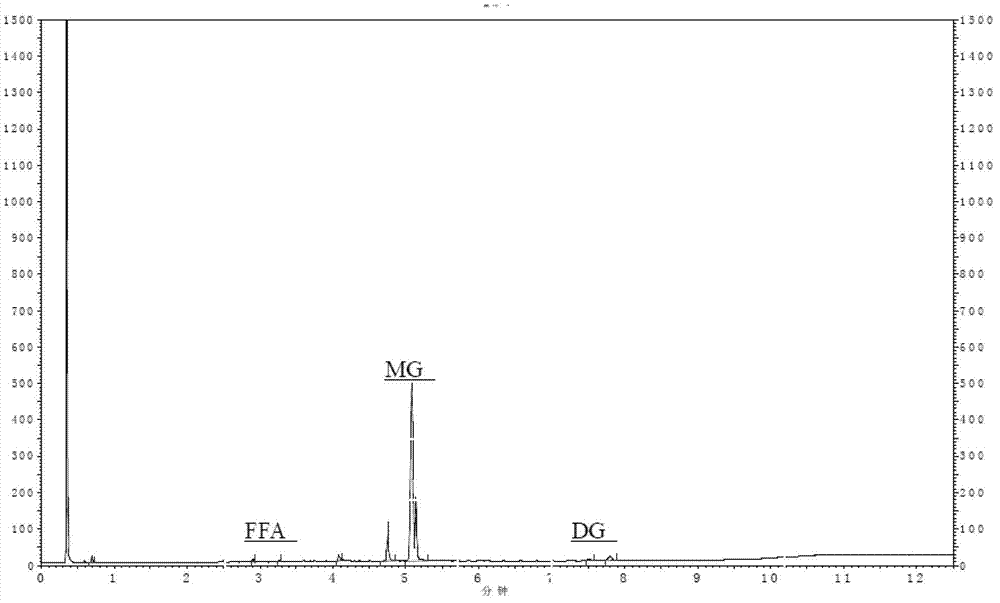

[0031] (1) Synthesis of fatty acyl monoglycerides: Take 100.0 g of soybean oil and add it to the reactor, and add K 2 CO 3 / HT solid base catalyst (for the preparation method refer to Cai Jing, "Research on the Preparation of Biodiesel from Rapeseed Oil Catalyzed by Solid Base Catalyst", Hefei University of Technology Master's Thesis (Chapter 3), 2009) 0.5g, glycerin 40.0g reactor pumping Vacuum to a pressure of 2000 Pa, while stirring continuously, start timing when the temperature reaches 220°C, and after the transesterification reaction for 2 hours. After the reaction liquid is filtered by suction, it is allowed to stand and separate for 45 minutes. The upper layer is the glyceride layer and the lower layer is the glycerin layer; the glycerin layer and the glyceride layer are successively released. The glyceride layer was analyzed by...

Embodiment 2

[0036] The synthesis and purification process diagram of high-purity fatty acyl monoglyceride in this embodiment is as follows figure 2 Shown:

[0037] (1) Synthesis of fatty acyl monoglycerides: Take 100.0g of hydrogenated palm oil and add it to the reactor, add K 2 CO 3 / HT solid base catalyst (for the preparation method refer to Cai Jing, "Research on the Preparation of Biodiesel from Rapeseed Oil Catalyzed by Solid Base Catalyst", Master's Thesis of Hefei University of Technology (Chapter 3), 2009) 0.6g, glycerin 60.0g, reactor pumping Vacuum until the pressure is 400 Pa, while stirring continuously, start timing when the temperature reaches 190°C, and after the transesterification reaction for 5 hours. After the reaction liquid is filtered by suction, it is allowed to stand and separate for 30 minutes. The upper layer is the glyceride layer and the lower layer is the glycerin layer; the glycerin layer and the glyceride layer are successively released. The glyceride layer wa...

Embodiment 3

[0041] The synthesis and purification process diagram of high-purity fatty acyl monoglyceride in this embodiment is as follows figure 2 Shown:

[0042] (1) Synthesis of fatty acyl monoglycerides: Take 100.0g of hydrogenated soybean oil and add it to the reactor, add K 2 CO 3 / HT solid base catalyst (for the preparation method refer to Cai Jing, "Research on the Preparation of Biodiesel from Rapeseed Oil Catalyzed by Solid Base Catalyst", Master's Thesis of Hefei University of Technology (Chapter 3), 2009) 1.0g, 25.0g glycerin, reactor pumping Vacuum until the pressure is 10000 Pa, while stirring continuously, start timing when the temperature reaches 230°C, and after the transesterification reaction for 1 hour. After the reaction liquid is filtered by suction, it is allowed to stand and separate for 30 minutes. The upper layer is the glyceride layer and the lower layer is the glyceride layer; the glycerin layer and the glyceride layer are successively released. The glyceride lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com