Method for synthesizing and purifying high-purity fatty acyl monoglyceride

A technology of fatty acyl monoglyceride and purification method, applied in the field of food emulsifier preparation, can solve problems such as difficulty in breaking through 60%, increase process complexity, etc., and achieve the effects of shortening process, saving equipment investment and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

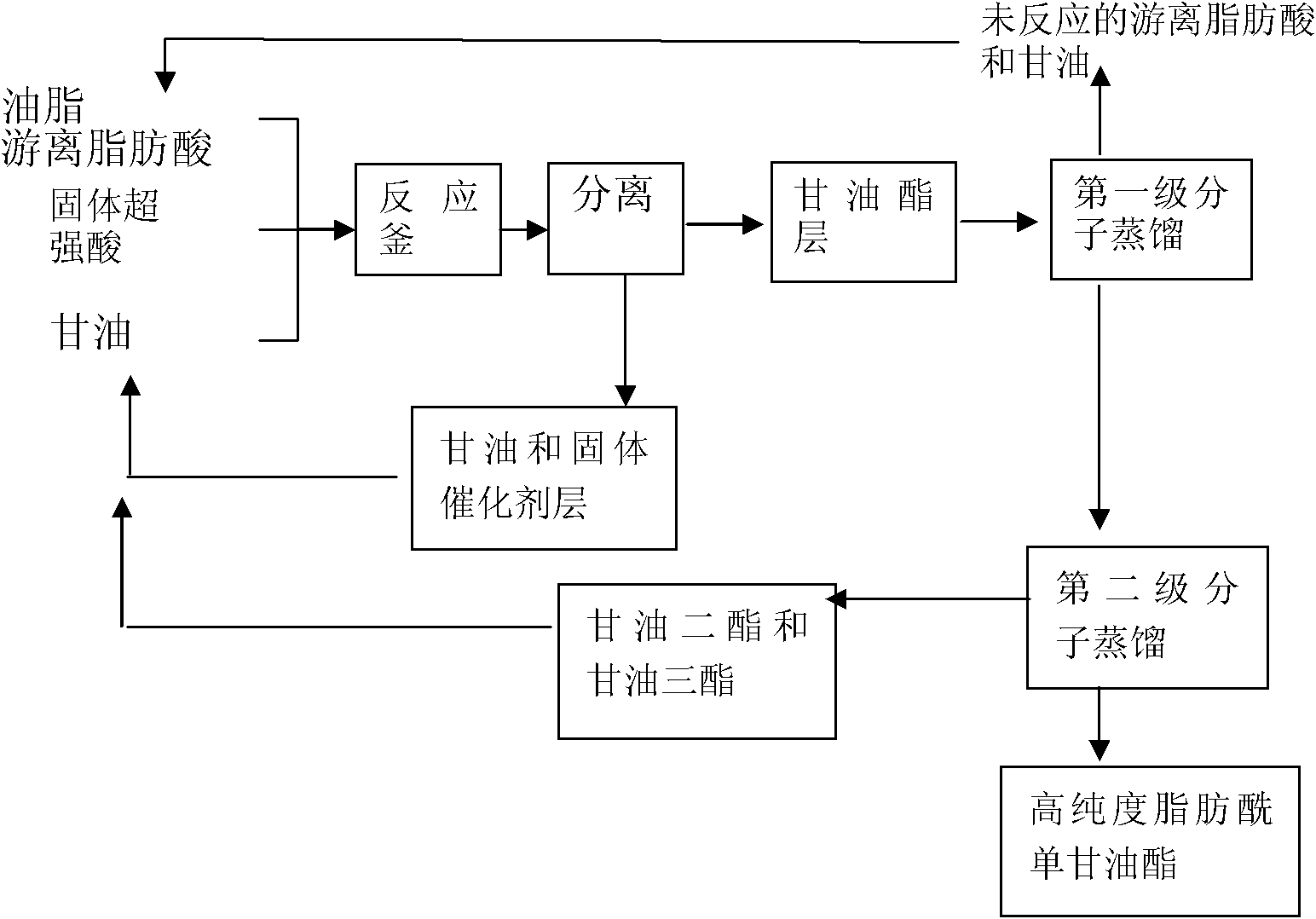

[0032] The synthesis and purification process route diagram of the high-purity fatty acyl monoglyceride of the present embodiment is as follows figure 2 Shown:

[0033] (1) Synthesis of fatty acyl monoglycerides: Get 60g of soybean oil and 40g of soybean oil fatty acid into the reactor, add SO 4 2- / ZrO 2 -Al 2 o 3Solid acid catalyst (preparation method is CN02151526.3 with reference to publication number, the name is called " a kind of granular solid superacid catalyst and preparation method " Chinese patent) 0.3g, and reactor is evacuated to pressure and is 2000Pa, constantly stirs simultaneously, waits for Start timing when the temperature reaches 170°C, add 40g of glycerin (the ratio of the number of moles of fatty acids in soybean oil and soybean oil fatty acid to the number of moles of glycerin is 1:1.25) dropwise into the reaction kettle, the time of adding drops is 30min, and reflux Esterification and transesterification; control the temperature of the cooling wa...

Embodiment 2

[0037] The synthesis and purification process route diagram of the high-purity fatty acyl monoglyceride of the present embodiment is as follows figure 2 Shown:

[0038] (1) Synthesis of fatty acyl monoglycerides: Take 80g of hydrogenated oil and 20g of stearic acid into the reactor, add SO 4 2- / ZrO 2 -Al 2 o 3 Solid acid catalyst (preparation method is CN02151526.3 with reference to publication number, and the name is called " a kind of granular solid superacid catalyst and preparation method " Chinese patent) 0.2g, and reactor is evacuated to pressure and is 400Pa, constantly stirs simultaneously, waits for Start timing when the temperature reaches 200°C, add 48g of glycerin (the ratio of the moles of fatty acids in hydrogenated oil and stearic acid to the moles of glycerol is 1:1.5) dropwise into the reactor, and the time for adding drops is 40min. Reflux esterification and transesterification; control the cooling water temperature in the reflux condenser, so that the...

Embodiment 3

[0042] The synthesis and purification process route diagram of the high-purity fatty acyl monoglyceride of the present embodiment is as follows figure 2 Shown:

[0043] (1) Synthesis of fatty acyl monoglycerides: get stearic acid 100g into the reactor, add SO 4 2- / ZrO 2 -Al 2 o 3 Solid acid catalyst (preparation method is CN02151526.3 with reference to publication number, the name is called " a kind of granular solid superacid catalyst and preparation method " Chinese patent) 0.5g, and reactor is evacuated to pressure and is 10000Pa, constantly stirs simultaneously, waits for Start timing when the temperature reaches 230°C, add 32g of glycerin (the ratio of the number of fatty acids in stearic acid to the number of moles of glycerol is 1:1) dropwise into the reaction kettle for 45 minutes to carry out reflux esterification and transesterification reaction; control the temperature of the cooling water in the reflux condenser, so that the water generated by the esterifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com