A cyclohexane oxidation reactor and its use method

An oxidation reactor, cyclohexane technology, applied in the preparation of oxidation reaction, chemical instruments and methods, chemical methods for reacting liquid and gas medium, etc. It can improve the flow conditions and improve the selectivity of the problems such as the increase of gas holdup.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

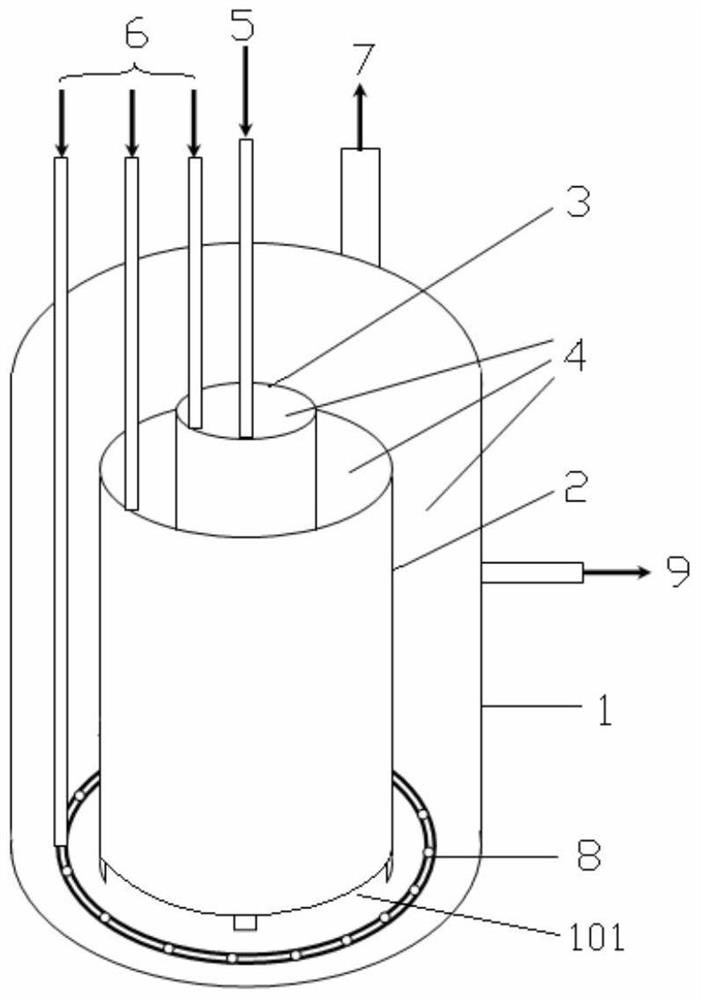

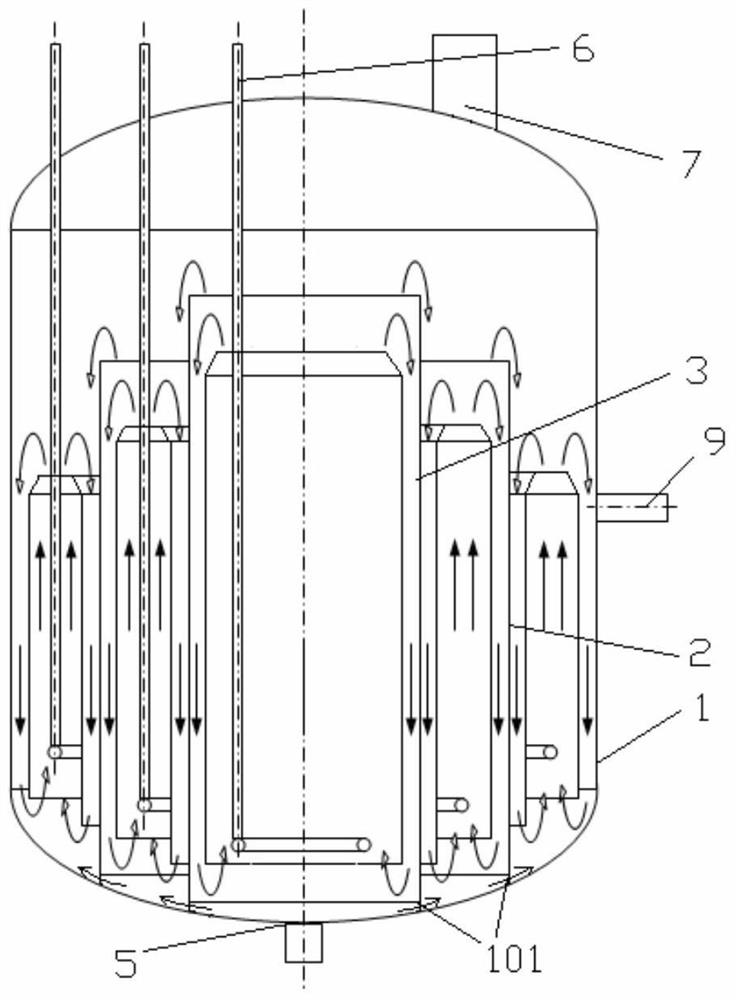

[0047] see figure 1 , the reactor housing 1 of the cyclohexane oxidation reactor is sleeved with a multi-layer guide tube, which is a two-layer guide tube in this embodiment, including a first guide tube 3 located in the center and a second guide tube located on the outside Flow tube 2, two flow guide tubes are arranged coaxially with the reactor shell 1, and have different diameters, which divide the reactor shell 1 into a three-stage annular area 4, and the height of the flow guide tubes is stepped from the center to the outside Lower, and the bottom of the first draft tube 3 and the second draft tube 2 and the bottom of the reactor shell 1 leave a water gap 101, so that the three-stage annular area can pass through the draft tube and the bottom of the shell The water gap 101 between them flows step by step, and can also be overflowed in series through the top step by step. The first guide tube 3 in the center is connected to the liquid inlet 5, and the annular area 3 of eac...

Embodiment 2

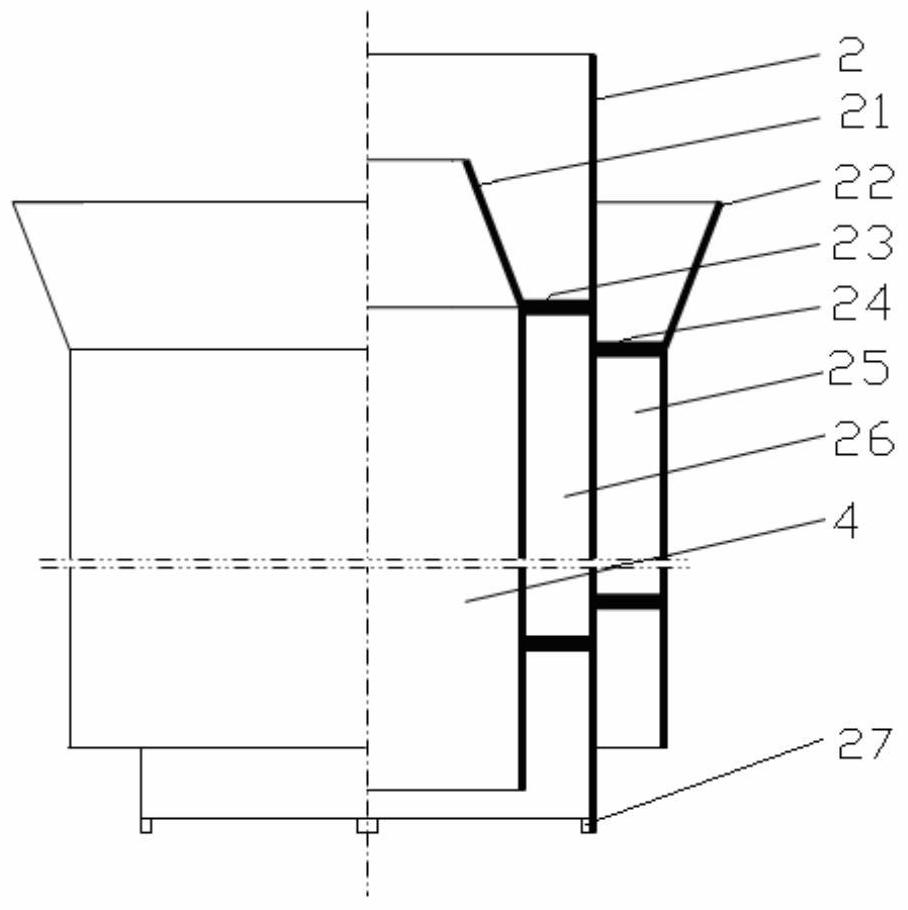

[0055] see in conjunction figure 2 with image 3 , the structure of the reactor in this example is the same as in Example 1, the difference is that the draft tube in this example is a double-loop flow guide tube, specifically as figure 2 As shown, taking the second guide tube 2 as an example to illustrate the structure of the double circulation guide tube, the inner wall and the outer wall of the second guide tube 2 are coaxially fixed with a cylindrical inner circulation baffle 21 and an outer circulation flow The baffle 22, two circulation baffles are respectively fixed on the inner side and the outer side of the second flow guide tube 2 by the inner circulation fixing rib 23 and the outer circulation fixing rib 24, between the inner circulation baffle 21 and the second flow guide tube 2 1. An inner circulation area 26 and an outer circulation area 25 that circulate up and down are formed between the outer circulation baffle plate 22 and the second guide tube 2, and the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com