Preparation method of high-strength TPS starch for degradable materials

A degradable material and high-strength technology, applied in the direction of sustainable manufacturing/processing, sustainable packaging industry, climate sustainability, etc., can solve the problems of breaking strength and elongation of molding materials, poor mutual adhesion, cost reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

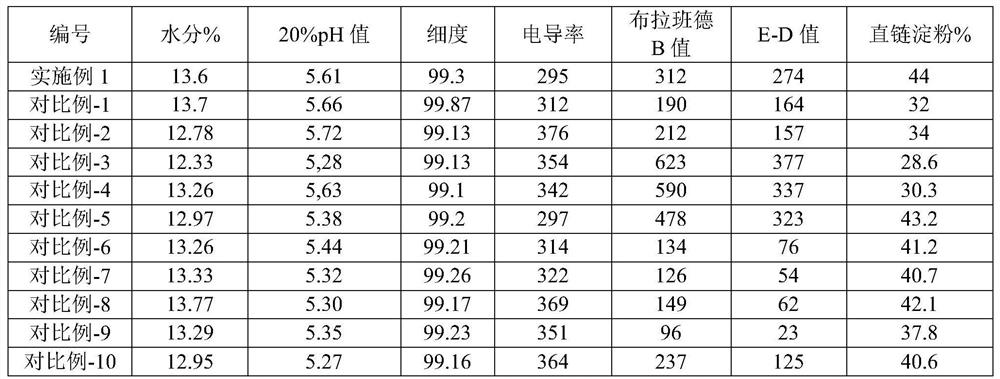

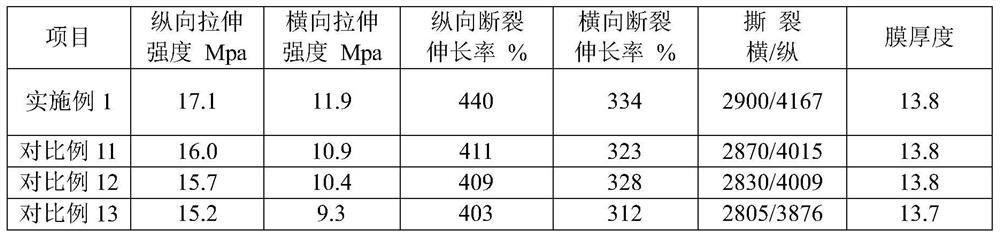

Embodiment 1

[0062] (1.1) be that 500 gram cornstarch and 500 gram pea starch and water are mixed into 40% slurry with absolute dry weight, under stirring condition control temperature is 58 ℃, add 4% liquid caustic soda to regulate the pH of starch slurry to be 5.2, then Add 2.6 grams of calcium chloride, activity unit of 2000 U / g, total amount of 1.8 grams of pullulase polysaccharase, timed reaction for 18 hours, then add 0.08 grams of copper sulfate and stir for 30 minutes to obtain starch primary slurry.

[0063] (1.2) Control the temperature of the obtained starch primary slurry at 26°C, add 16 grams of sodium chloride inhibitor, stir and react for 20 minutes, and add 4% liquid caustic soda to adjust the pH to 11.5, and then add 0.38 grams of phosphorus oxychloride for crosslinking agent, timed reaction for 30 minutes, then adjusted the pH to 9.5 with 15% hydrochloric acid, added 45 grams of vinyl acetate esterification agent to carry out esterification reaction for 2 hours, and obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com