Method for preparing cellulose nano-fibril film by utilizing wood powder

A technology of nanofibrils and lignocellulose, which is applied in the field of preparation of lignocellulose nanofibrils, can solve the problems of low hydrolysis yield and achieve the effect of simple and easy grinding treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] 1. Chemical pretreatment,

[0009] 1) Screen 60-70 mesh dry wood powder, accurately weigh 4g, add 300ml of toluene and ethanol mixture, the volume ratio is 2:1, into the Soxhlet extractor, extract at 90°C for 7h, remove For extracts such as ash, dry the extracted wood powder at room temperature for 24 hours to volatilize the toluene and ethanol on the surface;

[0010] 2) Transfer the dried wood powder into a 250ml beaker, add 150ml of distilled water, 1ml of glacial acetic acid and 1.5g of sodium chlorite, stir well with a glass rod, seal the mouth of the cup with plastic wrap, and put it in a constant temperature water bath at 75°C Heat for 1 hour; put a magnet in the cup for constant stirring to make the reaction more complete; add 1ml of glacial acetic acid and 1.5g of sodium chlorite to the beaker after 1 hour, and continue heating in a water bath at 75°C for 1 hour, repeating this 6 times , until the sample turns white; then filter with a vacuum filter pump and a...

Embodiment 2

[0025] Different cellulose nanofibers are prepared from poplar wood fibers: the chemical treatment steps are the same as above. After the chemical treatment is completed, the cellulose fibers are prepared with distilled water into an aqueous suspension with a mass fraction of cellulose fibers of 0.4%, a total of 500 ml, which are divided into five equal parts after thorough stirring, that is, the volume of each part is 100 ml. Then pour 300 ml of distilled water into each part of the cellulose fiber aqueous suspension, and stir thoroughly, so as to obtain five parts of the cellulose fiber water suspension with a mass fraction of 0.1%, each with a volume of 400 ml. Finally, the five aqueous cellulose fiber suspensions were ground for 1, 3, 7, 15 and 30 times respectively, and the rotation speed of the grinding disc was 1500 rpm. Thus, five cellulose nanofibers with different sizes were prepared, named CNF 1, CNF 3, CNF 7, CNF 15 and CNF 30, respectively.

Embodiment 3

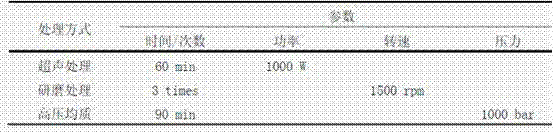

[0027] Ultrasonic treatment and high-pressure homogenization of nanocellulose fibrils / plexiglass (CNF / PMMA) nanocomposites: re-preparation of cellulose nanofibers from poplar wood fibers,

[0028] The specific operation is as follows: after the chemical treatment, it is also configured into three water suspensions with a mass fraction of cellulose fibers of 0.1%, and then two of them are subjected to 7 grinding treatments, and then ultrasonic grinding is performed on the basis of 7 grindings. Treatment and high-pressure homogenization, the ultrasonic power is 1000 W, the time is 60 min, and the pressure of high-pressure homogenization is 1000 bar, and the time is 90 min. In this way, different cellulose nanofibers are prepared, and then a suction filtration operation is performed to prepare a cellulose nanofiber film, and then a corresponding nanocomposite film is prepared by an impregnation method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com