Method for using recycled nylon for preparation of polyamide powder

A technology of polyamide powder and recycled nylon, which is applied in the field of advanced rapid manufacturing, can solve problems that are not suitable for large-scale industrial applications, and achieve the effects of solving the shortage of raw materials, high economic benefits, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

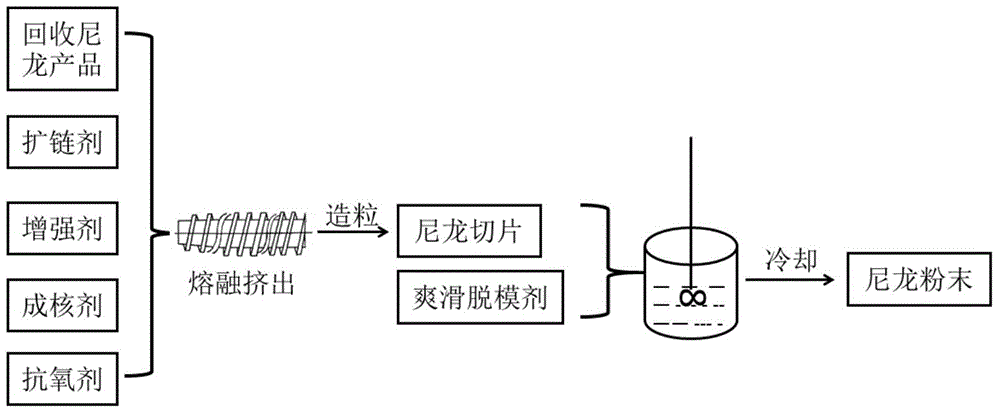

Method used

Image

Examples

Embodiment Construction

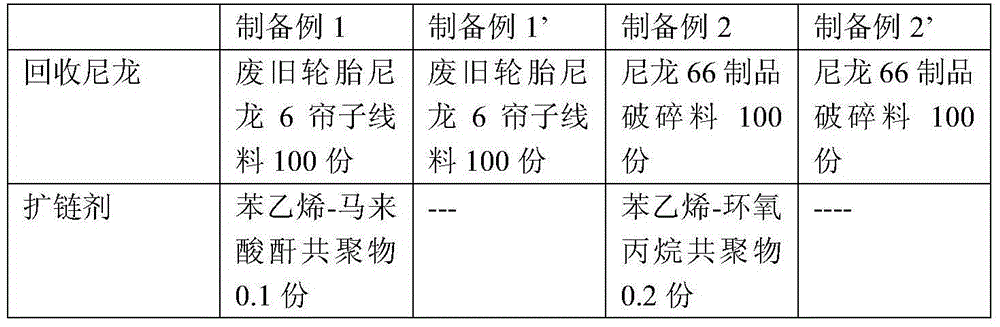

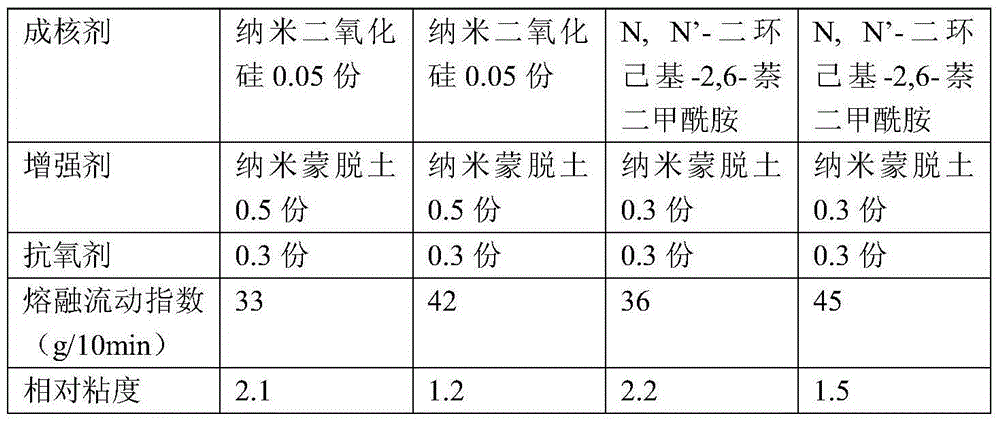

[0032] The present invention will be further described below in conjunction with specific examples.

[0033] (1) Raw materials used in the experiment

[0034] Recycled nylon: waste tire nylon 6 cord material and nylon 66 product crushed material, produced by Shenzhen Yejia Metal Plastic Recycling Resource Recycling Company.

[0035] Chain extender: styrene-maleic anhydride copolymer and styrene-propylene oxide copolymer, produced by BASF.

[0036] Antioxidant: the composition of antioxidant 1098 and antioxidant 168, the mass ratio is 1:1, produced by BASF Ciba, Germany.

[0037] Nucleating agent: nano-silica, Beijing Deke Shimadzu Technology Co., Ltd.; N,N'-dicyclohexyl-2,6-naphthalene dicarboxamide, produced by Shanxi Chemical Industry Research Institute.

[0038] Enhancer: nano-montmorillonite, produced by American NANOMER Company.

[0039] Smooth release agent: stearyl erucamide, produced by British Croda Company.

[0040] Solvent: polyethylene glycol, molecular weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com