Receiving cavity for lower limb prosthesis and preparation method thereof

A technology of sockets and prostheses, which is applied in the field of sockets and preparations of lower limb prostheses, can solve the problems of being unable to afford the cost of assembling sockets, failing to meet the needs of the society, and high costs, so as to improve comfort and function transfer performance, The effect of reducing the requirement of professional level and increasing the degree of personalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

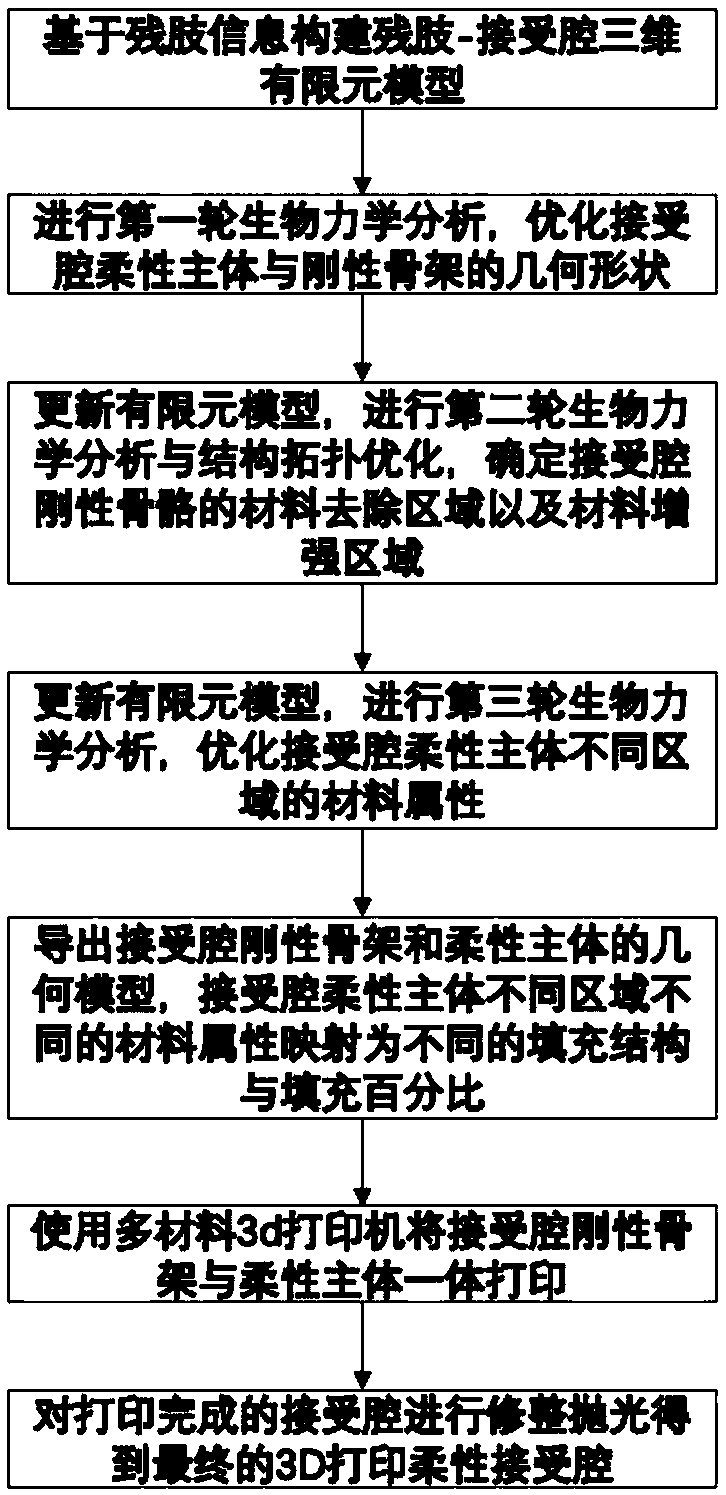

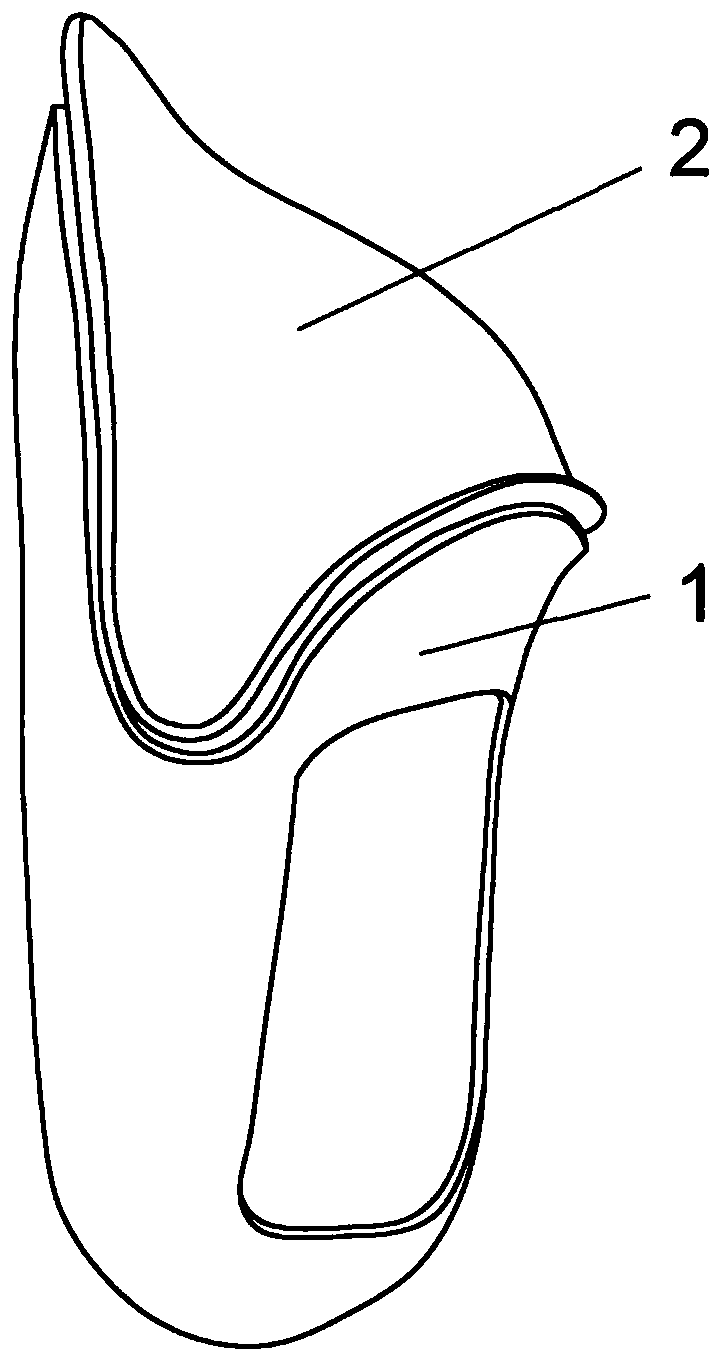

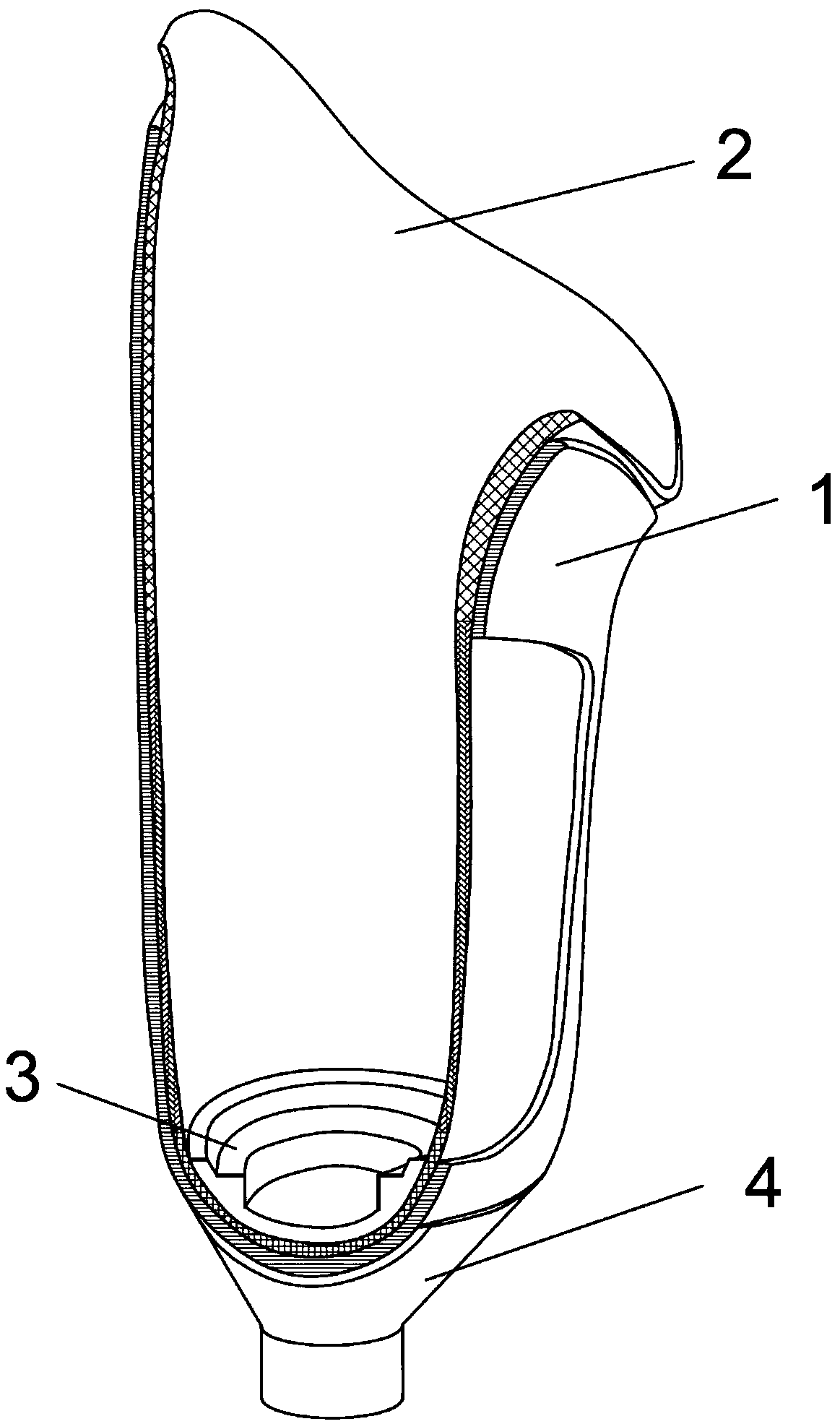

[0038] The invention provides a socket for lower limb prosthesis and its preparation method. By constructing a three-dimensional finite element model of the user's residual limb, the biomechanical analysis of the residual limb-socket interface is carried out, and the shape, material removal and reinforcement area of the socket are analyzed. , the elastic modulus of the material in the socket interface area and other key parameters are automatically adjusted and verified, and finally the designed and optimized socket is manufactured by means of additive manufacturing. By converting the professional experience of high-level prosthetic technicians and the subjective feelings of users into measurable scientific basis, the requirements for the professional level of production personnel in the process of designing prosthetic sockets can be greatly reduced, the design process can be simplified, and socket design costs can be reduced. cost. The shape-controllable characteristics of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com