Earthed telescopic meshed-type civil electrical connecting device as well as plug and socket thereof

A technology for electrical connection plugs and connection plugs, which is applied in the direction of two-component connection devices, parts of connection devices, coupling devices, etc., can solve the problems of insecurity, high risk, and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

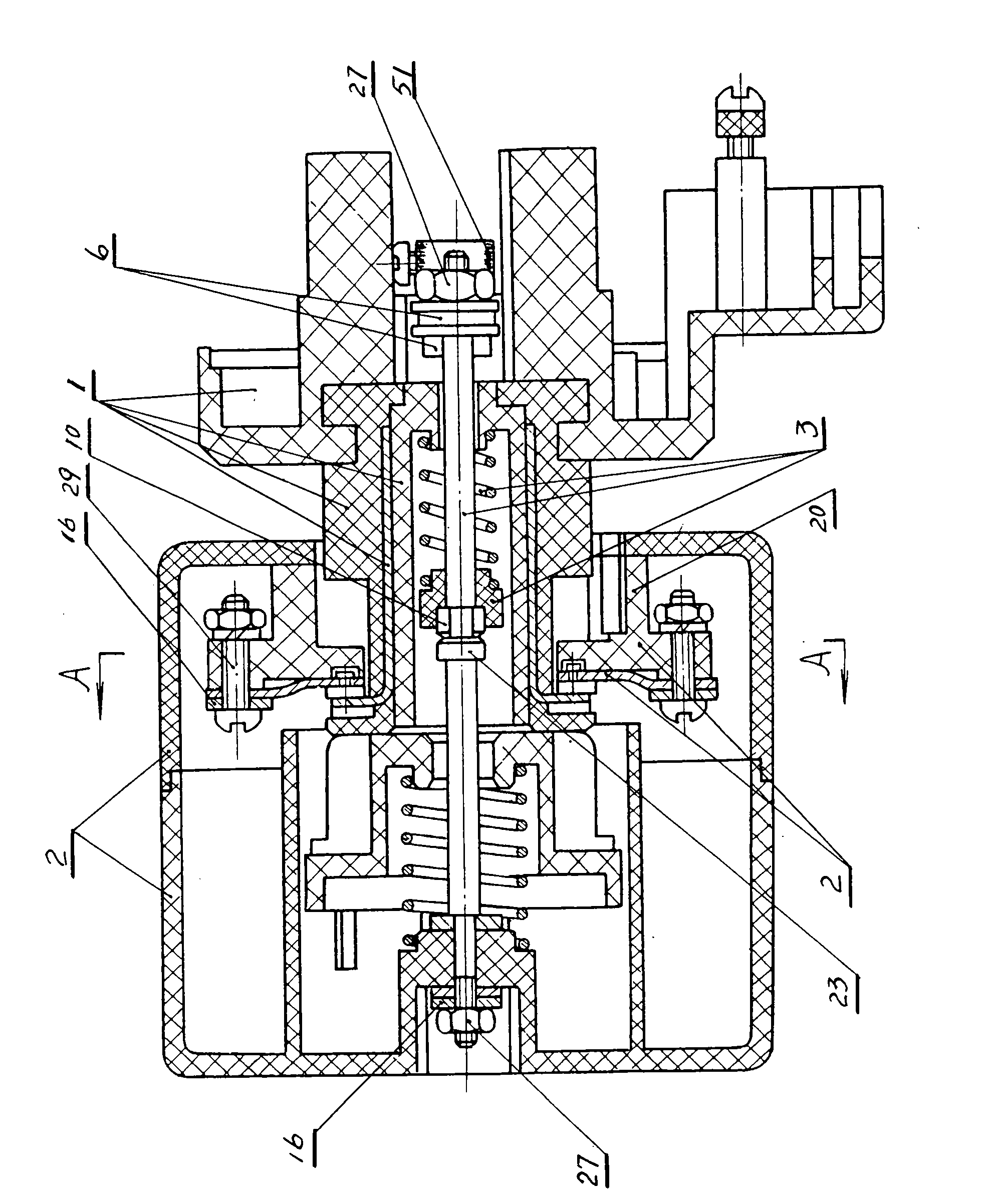

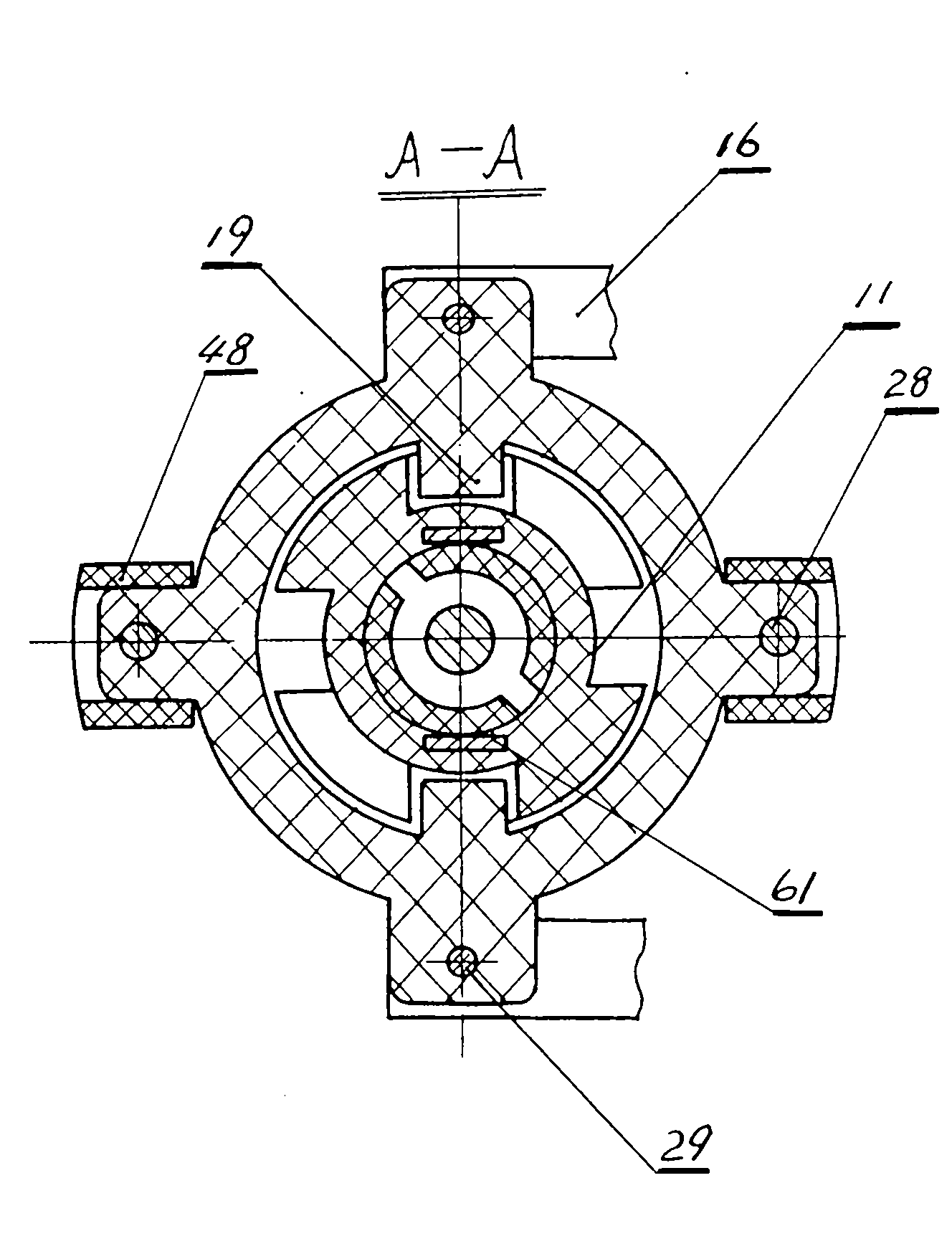

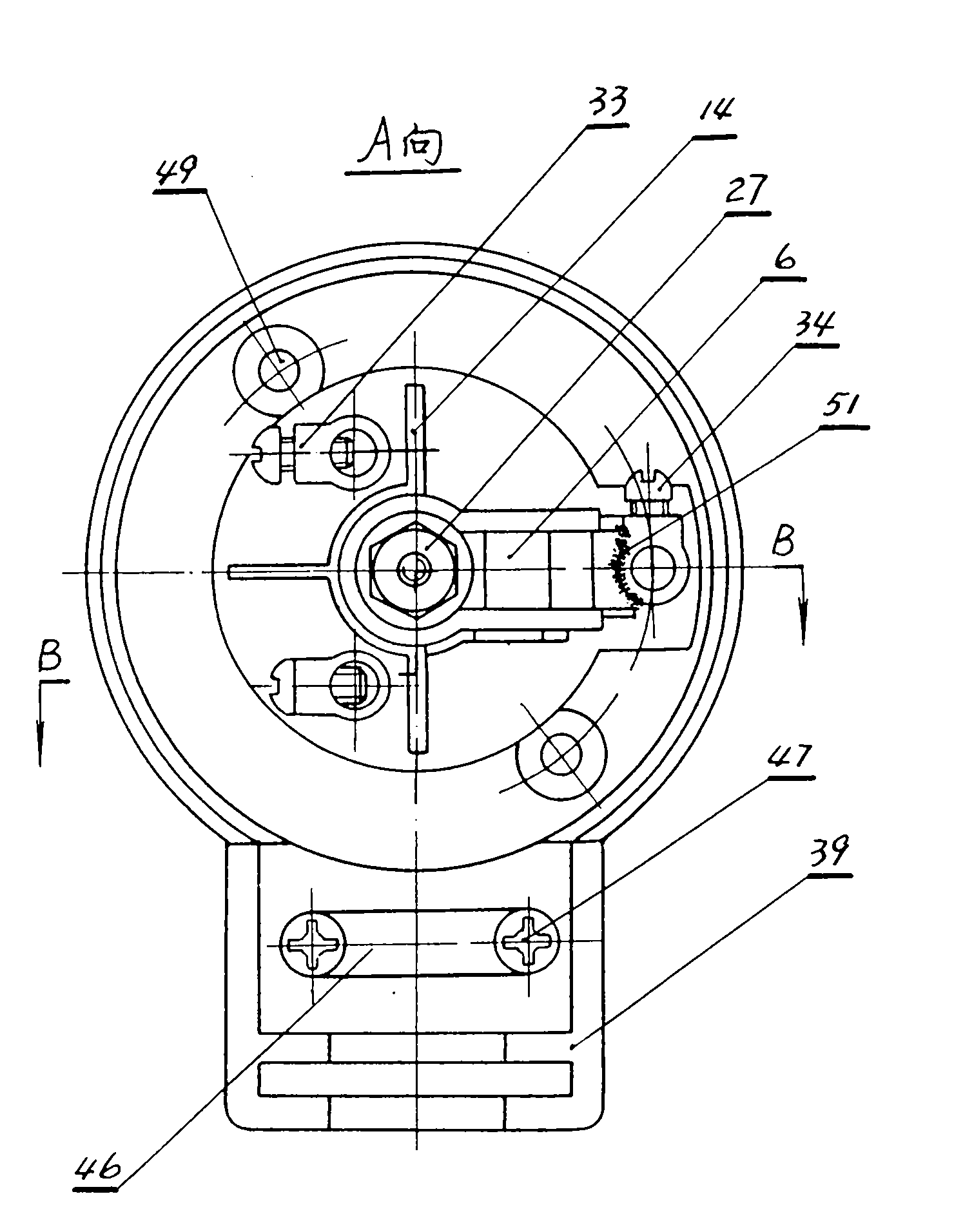

[0061] Please refer to Figure 1 to Figure 33 . First, according to the required specification, shape, size and appearance design, process the alignment setting consisting of the connecting plug plug body (7) with the connecting plug operating body front cover (39) and the connecting plug operating body rear cover (40) There is a guide positioning groove (11) and a conductive metal body A (61) with a sleeve type terminal (33) riveted at one end and a metal contact A (8) at the other end and welded together with the sleeve type terminal The rotating resilient engagement type electrical connection plug (1) of the flexible copper cable (6); similarly, according to the required specification, shape, size, appearance design, process the connecting plug that is provided with the base positioning card (48) Socket front cover (24) and the alignment sleeve (32) that is provided with positioning chute, ground metal body positioning step seat (36) connects socket back cover (26) and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com