Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer, tire parts, tire tread/tread pattern of pneumatic tires, etc., and can solve the problem of uneven wear of the shoulder landing, tread separation, uneven contact pressure, etc. problems, to achieve the effect of improving high-speed durability, suppressing uneven wear, and uniform ground contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

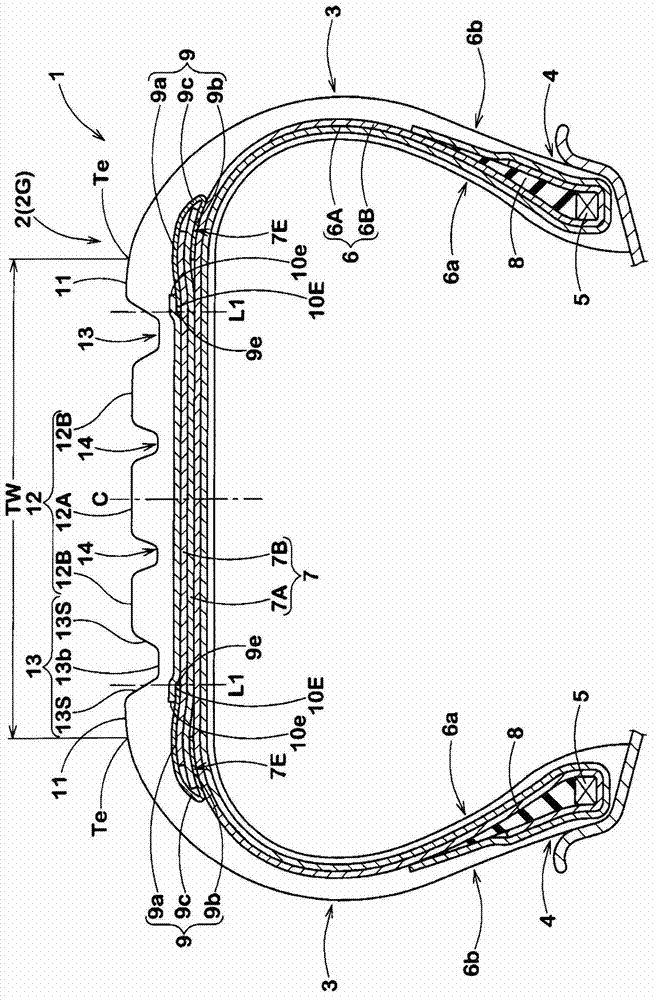

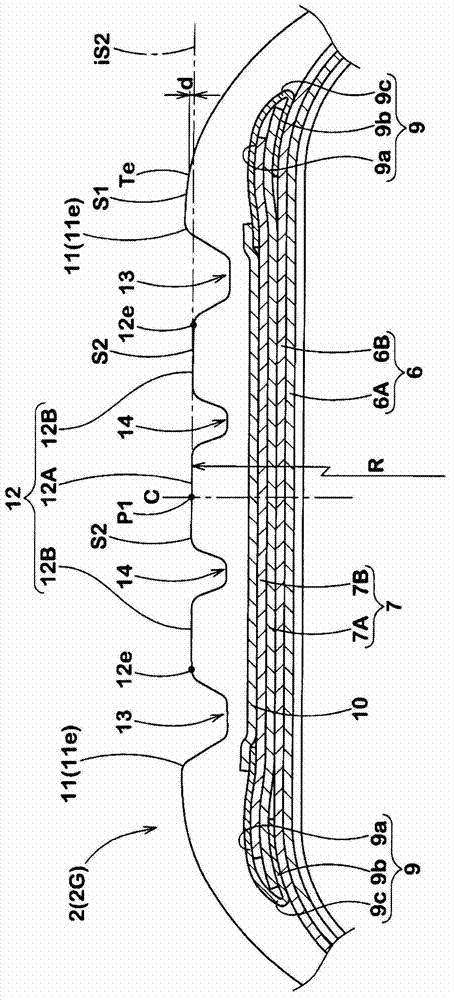

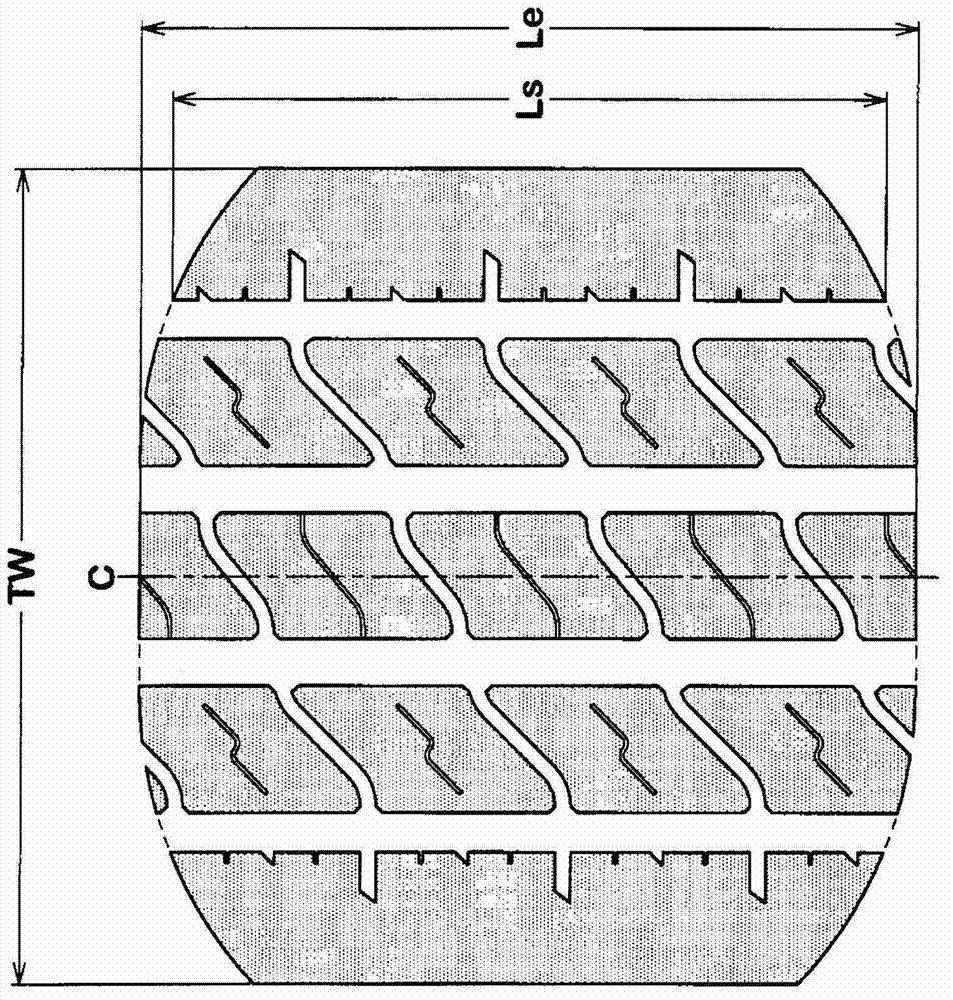

[0061] Prototype according to the specifications in Table 1 figure 1 The basic construction of the pneumatic tire of size 235 / 50R18 was carried out, and the durability was measured. The test method is as follows.

[0062] Durability:

[0063] The tire to be tested was run on a roller at a speed of 70 km / h under the conditions of a rim of 18×7JJ, an internal pressure of 180 kPa, and a load of 6.15 kN, and the distance traveled until the tire shoulder landed was damaged was measured. As a result, comparative example 1 was made into an index of 100, and this result shows that the durability is higher as the numerical value is larger.

[0064] The test results are shown in Table 1.

[0065] Table 1:

[0066]

[0067] ※The above distance d shows the value measured at the tread end

[0068] As a result of the test, it was confirmed that the tires of Examples 1 to 9 had improved durability compared to the tires of Comparative Examples 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com