Roll-shape configuration method of ultra-wide six-roll variable-crown cold continuous rolling mill

A technology of tandem cold rolling mill, configuration method, applied in the direction of profile control etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

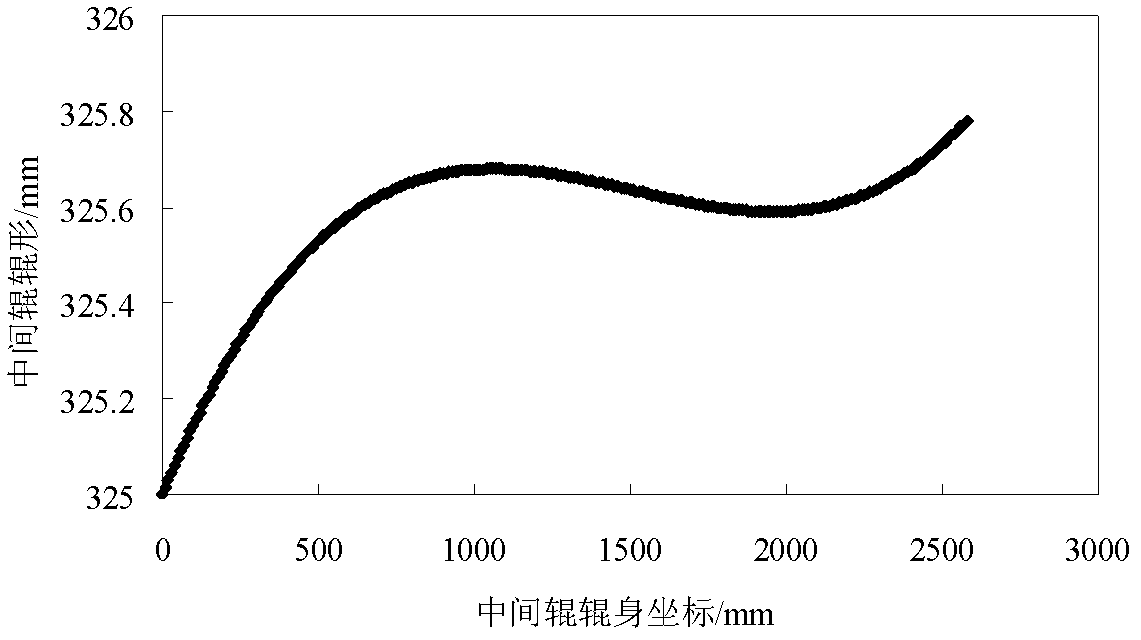

[0037] The technical scheme of the present invention will be further described below in conjunction with a specific embodiment of a 2180mm ultra-wide tandem cold rolling mill. The roll shape configuration adopts the small side wave shown in the previous formula (1) to control the roll shape of the work roll to reduce the reduction ratio of the edge of the strip to eliminate the local wave shape, and adopts the continuously variable crown intermediate roll shown in the formula (2) Roll shape control Symmetrical quadratic wave shape, use the variable crown support roll shown in formula (3) to uniform roll contact pressure between rolls, improve roll shape self-maintenance, and ensure the stability of shape control during the service life of the support roll , the specific roll shape configuration is as follows figure 1 shown.

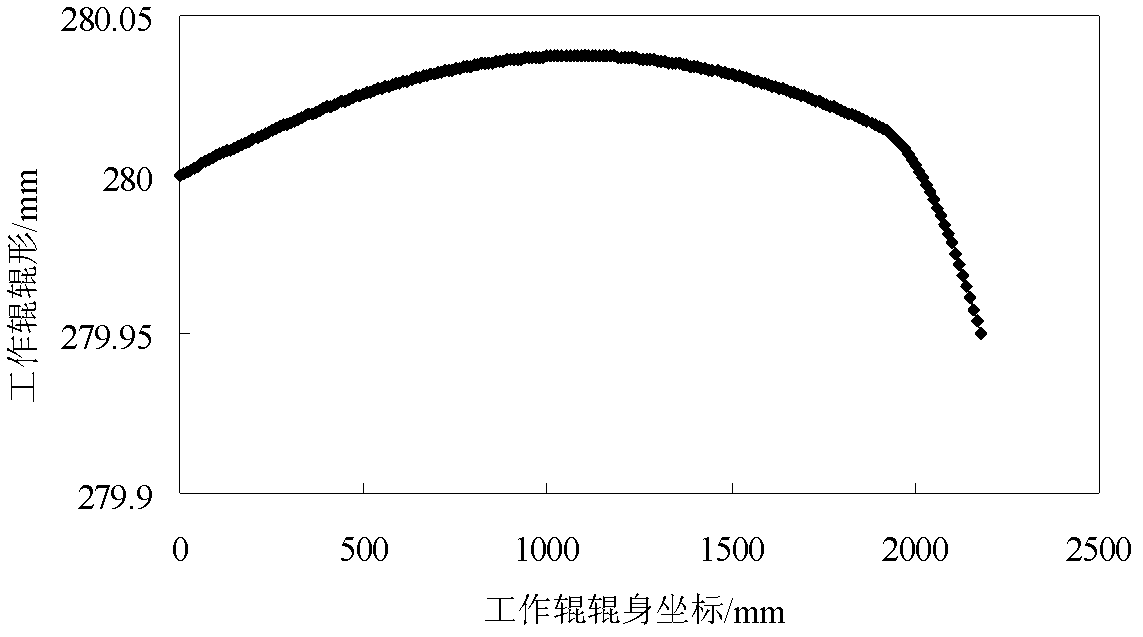

[0038] (1) Work roll shape design

[0039] It is known that the work roll body length L of a 2180mm tandem cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com