Self-hold electromagnet of built-in bi-directional position detection

A self-holding and electromagnet technology, applied in the direction of electromagnets with armatures, electromagnets, electromagnetic terminals/connectors, etc., can solve the problems of increasing the volume and quality of electromagnets, so as to improve self-holding force, reduce volume, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

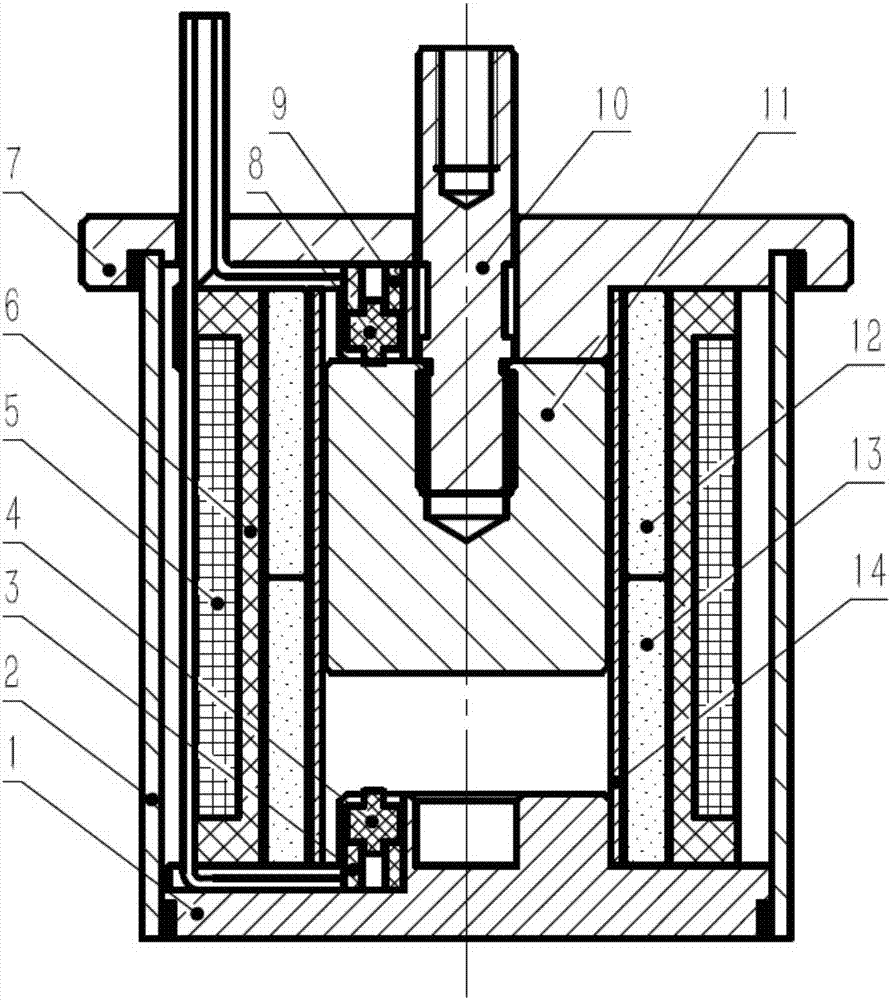

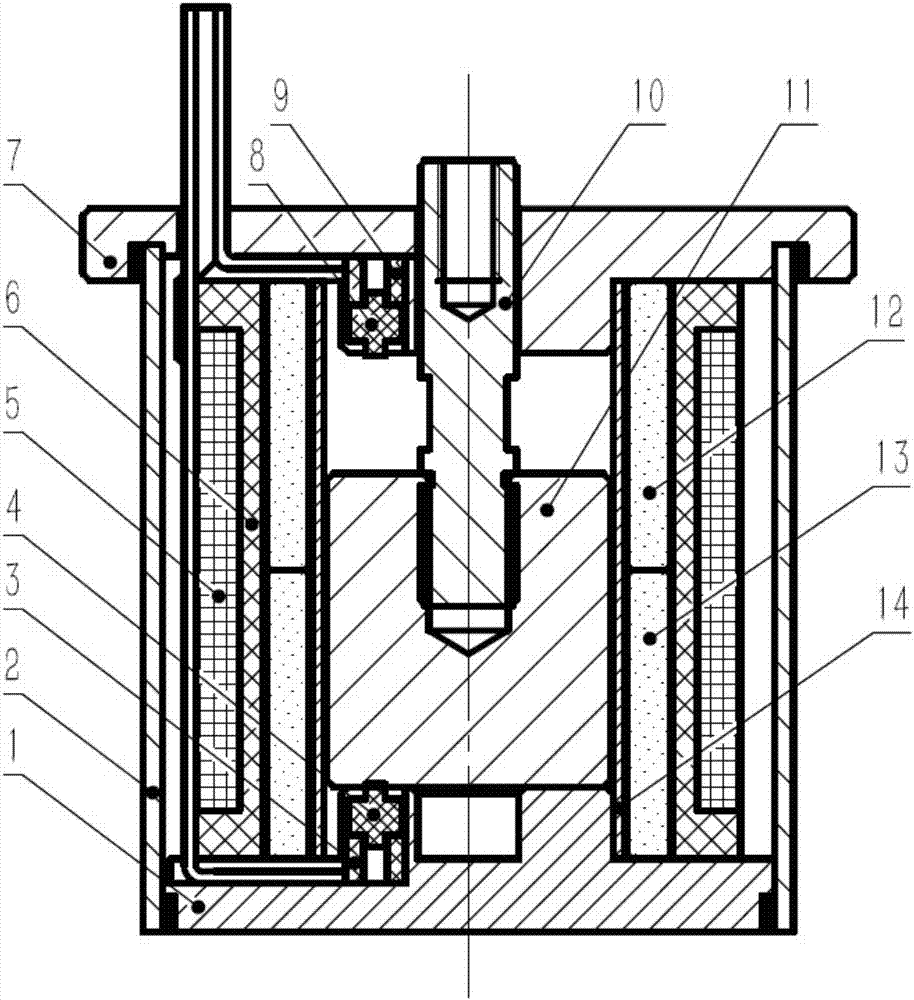

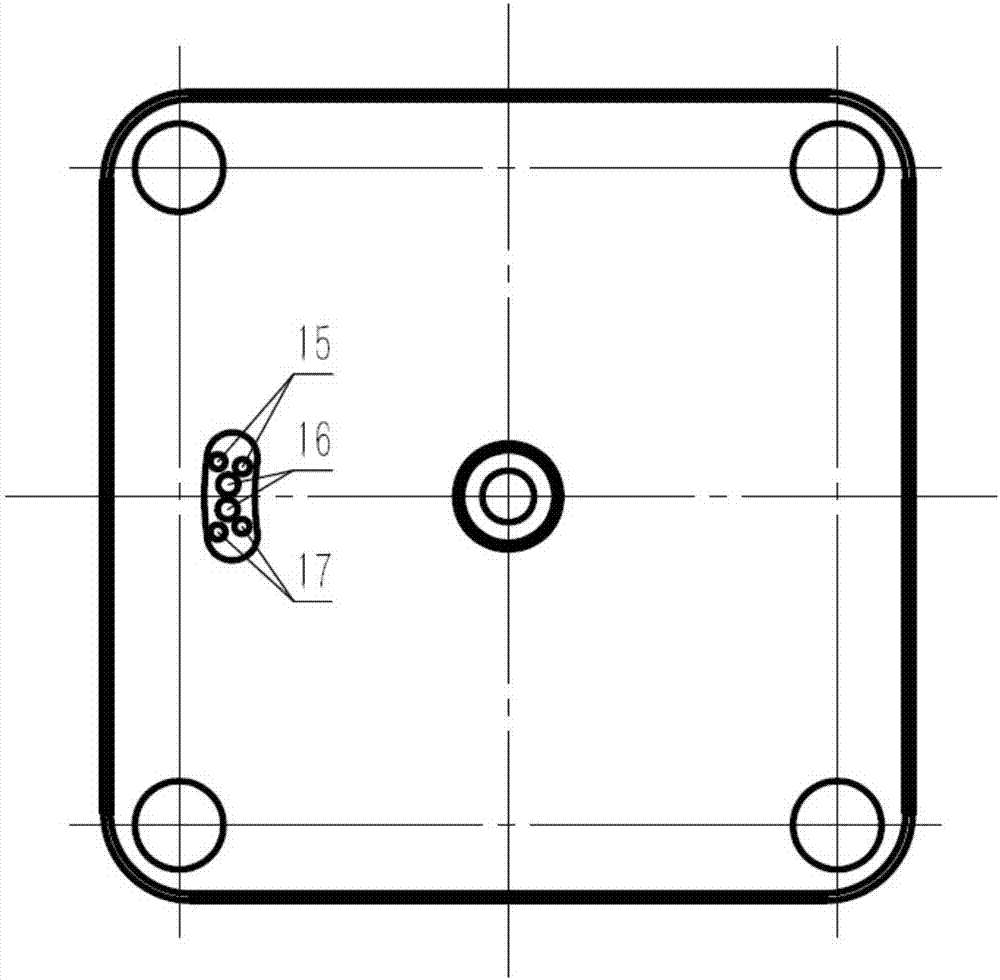

[0018] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0019] A self-holding electromagnet with built-in two-way position detection, including an output shaft 10, a piston 11, an upper end cover 7, a lower end cover 1, a guide cylinder 14, a magnetic steel, a coil skeleton 6, a coil 5 and a housing 2. The upper end The cover, the lower end cover, the piston and the housing are all magnetically conductive materials, and the output shaft is made of nonmagnetically conductive materials.

[0020] The upper end of the output shaft is vertically worn on the upper end cover, the lower end of the output shaft is coaxially connected to the piston, and the lower end cover is located below the piston. The piston is connected with the output shaft to form a movable part, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com