Shielding assembly for logger connector base

A joint seat and logging tool technology, which is applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve the problems of not being fully utilized, and achieve the effects of shortening the length of the tool, reducing interference, and optimizing the arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following description is merely exemplary in nature and is not intended to limit the invention, its application or uses.

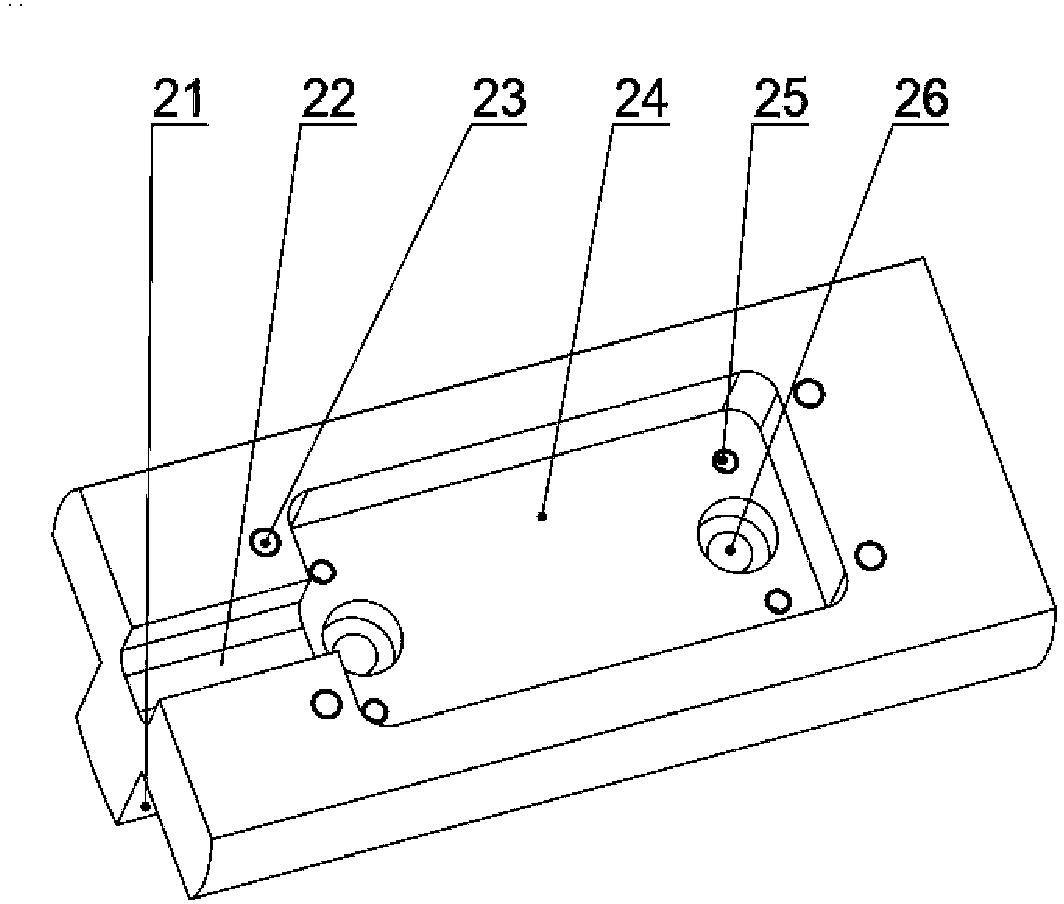

[0021] refer to figure 1 , figure 1 is a perspective view of an exemplary embodiment of a shield assembly for a tool subhead. In this embodiment, the shielding assembly may include a connector seat 11 , a pad 12 , and a shielding cover 14 . Preferably, the spacer 12 and the shielding cover 14 can be made of high-permeability materials, such as high-permeability stainless steel, which is conducive to better electromagnetic shielding. In addition, the shielding assembly may further include a high-voltage module 13 , M3 screws 15 , M2.5 screws 16 , and M4 screws 17 . The high-voltage module 13 can be fixed in the spacer 12 by M2.5 screws 16 , the shielding cover 14 can be installed on the upper surface of the spacer 12 by M3 screws 15 , and the spacer 12 can be installed in the joint seat 11 by M4 screws 17 . The spacer 12 and the shielding cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com