Apparatus and method for cleaning rubber blankets on rubber blanket cylinders

A technology of rubber cloth and cleaning cloth, applied in the field of rubber cloth device, can solve the problems of inability of printing press, high labor cost, poor printing quality, etc., and achieve the effect of optimizing contact pressure, high printing capacity, and reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

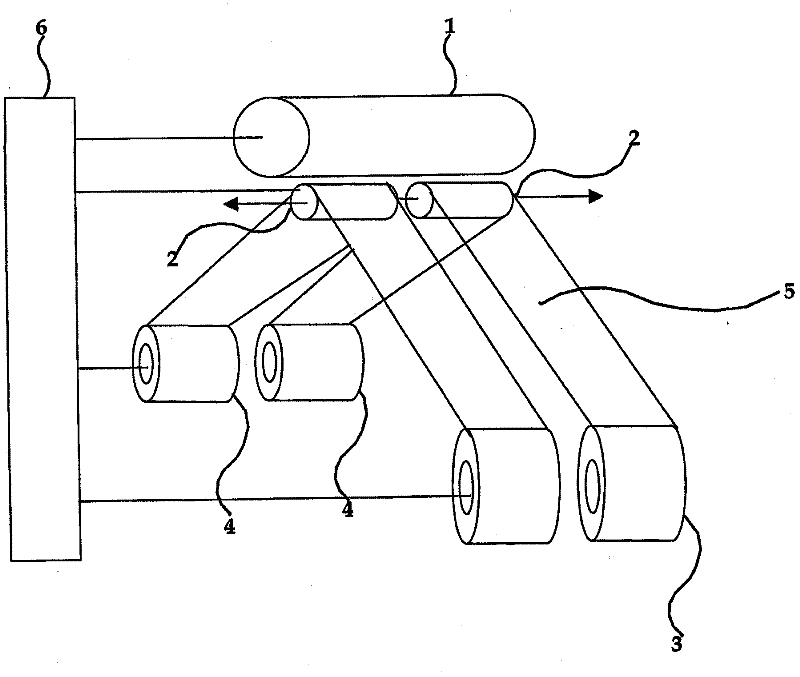

[0041] figure 1 A device for cleaning blankets according to the invention is schematically shown.

[0042] Among them, it can be clearly seen: a rubber cloth cylinder 1 with a rubber cloth pressed on its surface, a cleaning assembly 2 connected to each other, a cleaning cloth supply shaft 3 , a cleaning cloth winding shaft 4 and a cleaning cloth 5 . Sports transport equipment 6 in figure 1Not described in detail in , wherein these lines show that the moving transport device is connected to the blanket cylinder 1, the above-mentioned interconnected cleaning assembly 2, the above-mentioned cleaning cloth supply shaft 3 and the above-mentioned cleaning cloth winding shaft 4, It is also part of it. After the cleaning cloth is unrolled on the above-mentioned supply shaft 3, it is guided by the above-mentioned cleaning assembly 2, pressed against the rubber cloth with predetermined contact pressure, and then guided to the cleaning cloth winding shaft 4. Here, the aforementioned d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com