Offset printing method and device

A technology of offset printing and placing table, applied in the directions of printing devices, printing, printing machines, etc., can solve the problems of substrate printing accuracy, reduced reproducibility, undisclosed, unrealistic, etc., to prevent the deviation of printing accuracy and reproducibility , The effect of suppressing overlapping dislocation and overlapping dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

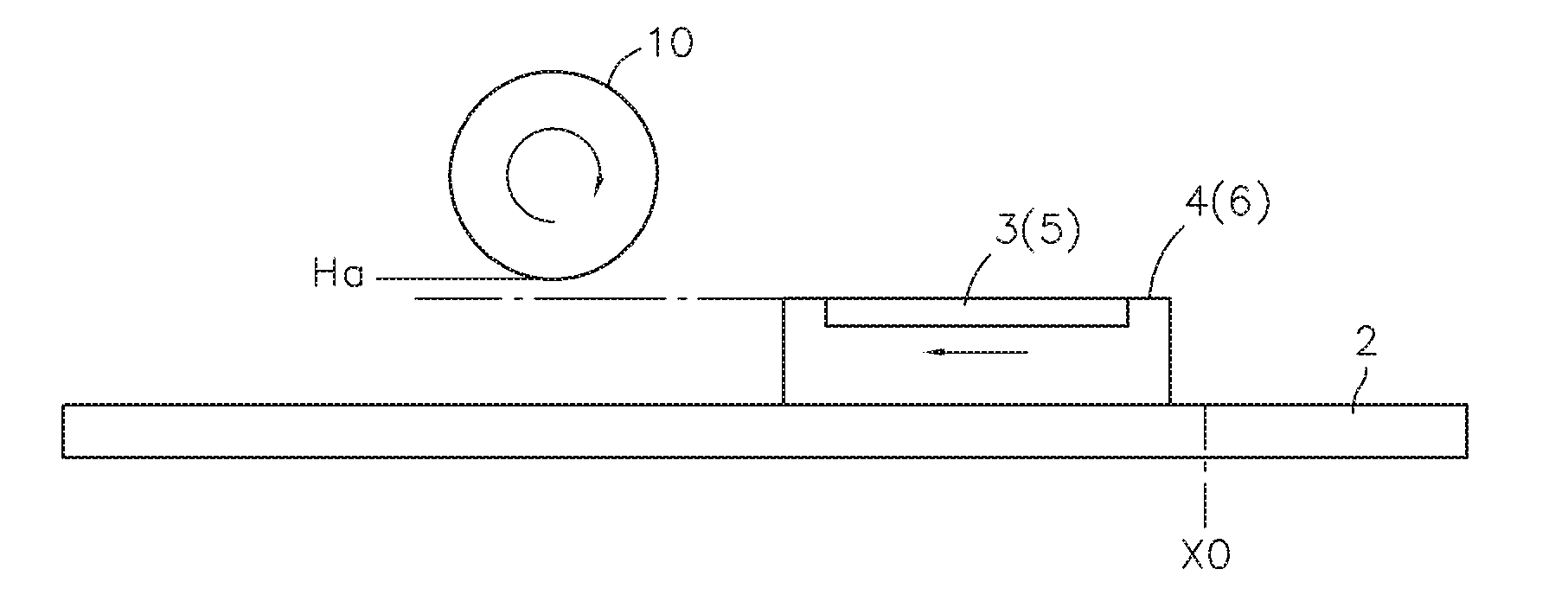

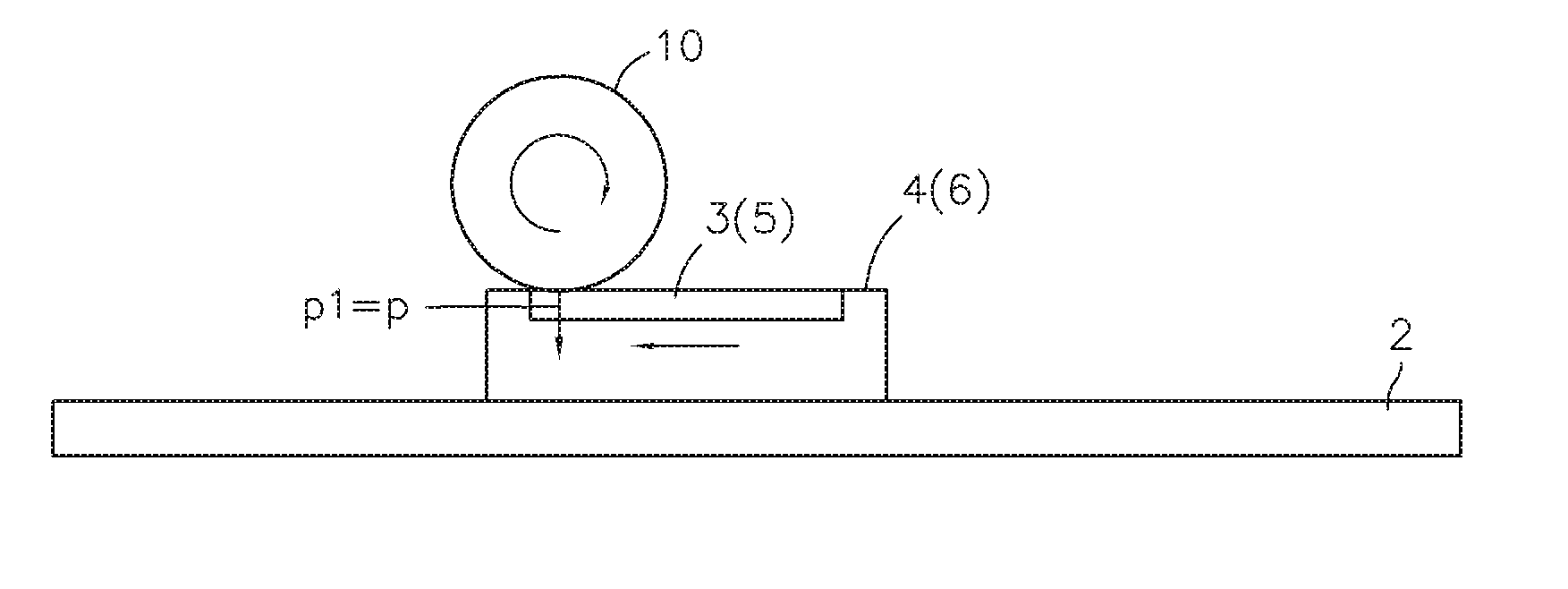

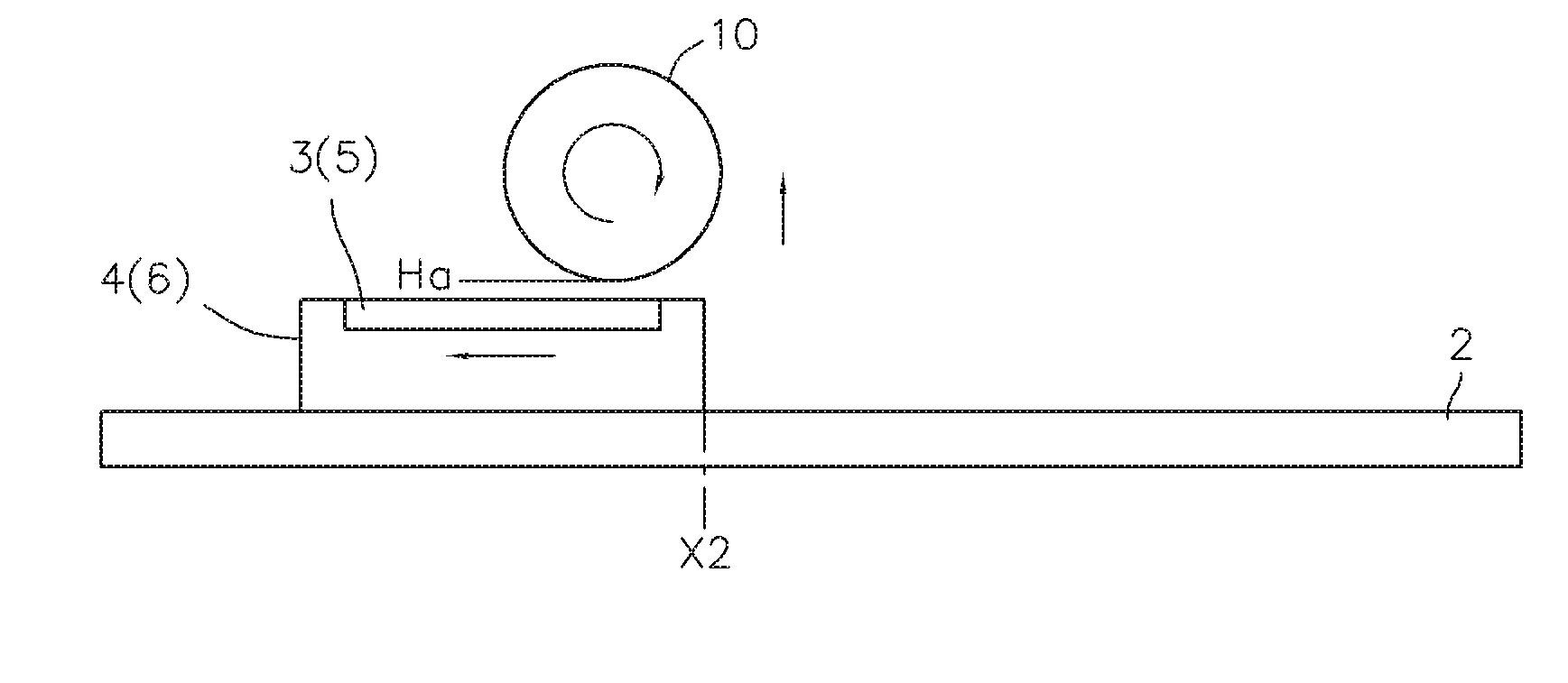

[0091] Figures 1 to 11B One embodiment of the offset printing method and apparatus of the present invention is shown, and has the following configurations.

[0092]That is, on the upper side of the horizontal pedestal 1 , there are provided guide rails 2 extending in one direction (X-axis direction), for example, a set of two guide rails 2 . On the guide rail 2, sequentially from one end side in the length direction of the guide rail 2 ( figure 1 The left side in the figure) are disposed with a plate mounting table 4 holding a plate 3 such as an intaglio plate on its upper surface, and a substrate mounting table 6 as a printing object mounting table holding a printing target substrate 5 on its upper surface. These mounting tables 4 , 6 are mounted so as to be slidable with respect to the guide rail 2 via independent guide blocks 2 a , and independently move (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com