Preparation methods of high temperature resistant anticorrosion potassium silicate coating and corresponding coat

A potassium silicate and anti-corrosion technology, which is applied in the scientific field, can solve problems such as harsh construction conditions, poor shielding performance, and unstable coatings, and achieve good thermal shock resistance, high temperature resistance, and improved thermal shock performance.

Active Publication Date: 2012-07-11

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Inorganic coatings represented by water-based zinc-rich coatings have good high temperature resistance, but the microporosity of the coating leads to poor shielding performance, premature failure of the coating, tendency to crack when the coating is thick, and harsh construction conditions, etc. shortcoming

Although the corrosion resistance can be improved by increasing the modulus of silicate, it is easy to gel when the modulus is high, and the coating is unstable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

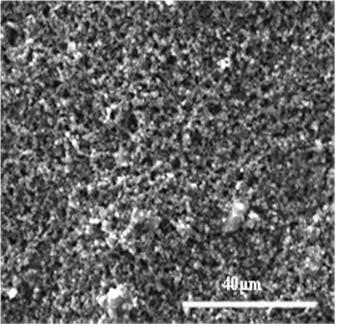

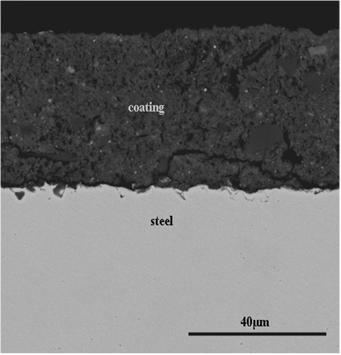

The invention relates to preparation methods of a high temperature resistant anticorrosion potassium silicate coating and a corresponding coat. The high temperature resistant anticorrosion potassium silicate coating is formed by a solute and a solvent, wherein the solute comprises a component A liquid potassium silicate having a module of 3.0-4.0 and a weight accounting for 30-80% of the total weight of the coating, and a component B which comprises nanometer Cr powder having a weight accounting for 1-15% of the total weight of the coating, aluminum triphosphate having a weight accounting for 3-20% of the total weight of the coating, Zn powder having a weight accounting for 5-20% of the total weight of the coating and Al2O3 having a weight accounting for 10-50% of the total weight of the coating; and the solvent is water, and the weight ratio of the solvent to the solute is 1:3-10. The method for preparing the coat through utilizing the coating comprises the following steps: spraying or brushing the coating on the surface of a sandblasted steel iron part, drying the surface for 5-10min, carrying out temperature maintenance for 0.5-4h according to a furnace temperature of 200-260DEG C, taking out the part, and air-cooling the part to obtain the coat. The coat of the invention has the characteristics of high temperature resistance, anticorrosion and water resistance, and has the advantages of good thermal shock resistance, nontoxicity, no pollution, and environmental protection benefiting.

Description

technical field [0001] The invention relates to science, and in particular provides a high-temperature-resistant and anti-corrosion potassium silicate coating mainly used for iron and steel materials and a preparation method of the corresponding coating. Background technique Ordinary steel such as carbon steel and cast iron is widely used in various fields of national economic construction as a class of economical materials, but its low corrosion resistance and oxidation resistance require corresponding protective measures. Stainless steel has good corrosion resistance at room temperature, but its oxidation resistance is poor when the temperature is high, especially in the salt spray environment. Organic coatings have a long history of application as protective coatings on metal materials, but one disadvantage of organic coatings is that they contain organic solvents, which are very harmful to the protection of the environment. On the other hand, most organic coatings hav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D1/02C09D5/10

Inventor 王成朱圣龙王福会

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com