Dynamic pressure gas radial bearing with axial variable stiffness and viscoelastic structure

A dynamic pressure gas bearing and viscoelastic technology, applied in the field of foil dynamic pressure gas bearing structure, can solve the problems of high processing level requirements, mechanical damage to the top foil, and complicated manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

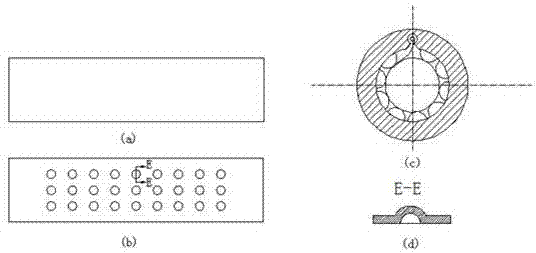

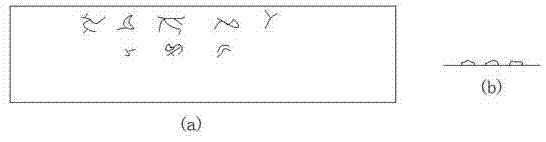

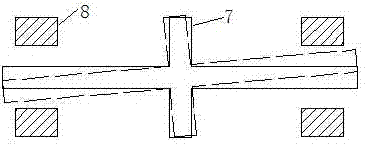

[0010] The invention discloses a foil dynamic pressure gas radial bearing with axially variable stiffness and viscoelastic structure for high-speed rotating machines. The bearing is composed of a bearing seat, supporting foil elements and positioning pins. Such as Figure 4 As shown, the foil element of the bearing has a three-layer structure: the top layer is a metal flat foil 1 with a smooth surface, the middle is a high-temperature-resistant viscoelastic rubber foil 2, and the bottom layer is a metal foil 3 with a bubble-like protrusion structure. The foil element provides structural rigidity and structural damping to the bearing. Such as Figure 4 As shown in (b), when making the support foil element, the viscoelastic rubber foil 2 is first fixed on the top flat foil 1, and then the top flat foil 1 and the bottom bubble-shaped protrusion foil 3 are together with the positioning pin 4 It is fixed at one end of the element by means of welding or gluing, and finally the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com