Display panel and preparation method

A technology of display panel and phase separation method, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. It can solve the problems of water-blocking layer fracture and poor flexibility, so as to improve water-blocking performance and possibility The effect of reducing and changing the process steps less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

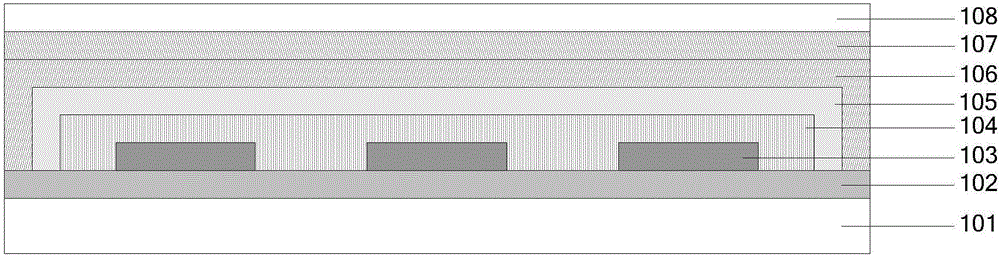

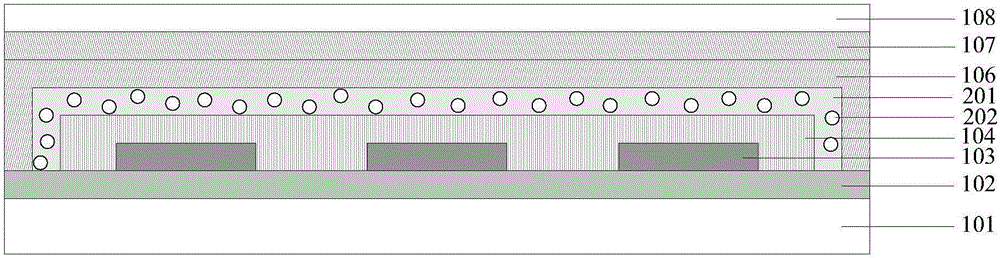

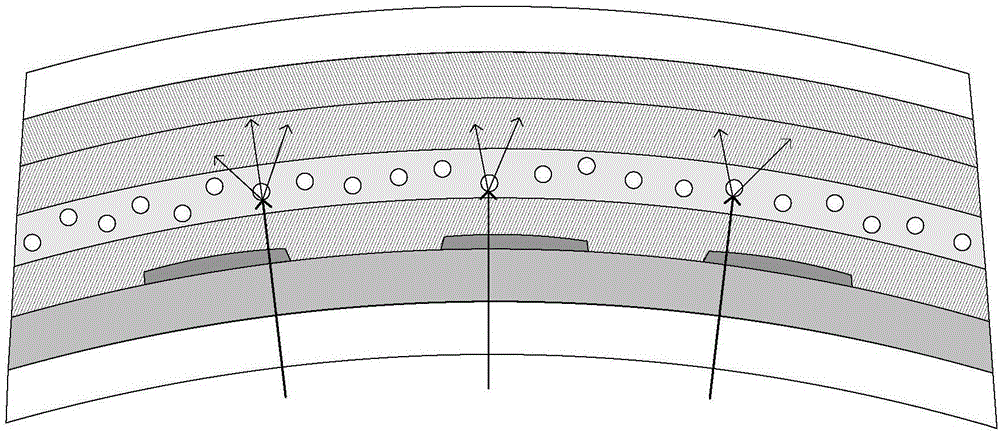

[0039] The embodiment of the present invention provides a display panel and a preparation method, which are used to disperse the stress on the stressed surface of the inorganic water-blocking layer during the bending process through the droplet microstructure in the organic buffer layer, and improve the performance of the inorganic water-blocking layer. The stress on the stress-bearing surface is relatively concentrated, and the inorganic water-blocking layer is broken due to the poor flexibility of the inorganic water-blocking layer, and a new water molecule erosion channel is formed at the fracture; and the droplet microstructure in the organic buffer layer Prolonging the penetration path of water molecules prolongs the time for water molecules to reach the light-emitting layer in the display panel, which improves the device life of the light-emitting layer; the display panel provided by the embodiment of the present invention has better water resistance than the display panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com