Ceramic chip of NOx sensor

A technology of nitrogen oxides and sensors, which is applied in the field of measurement or testing, can solve problems such as inaccurate concentration, and achieve the effects of simple preparation process, avoiding chamber collapse, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below with reference to the drawings and examples, but the present invention is not limited to the following embodiments.

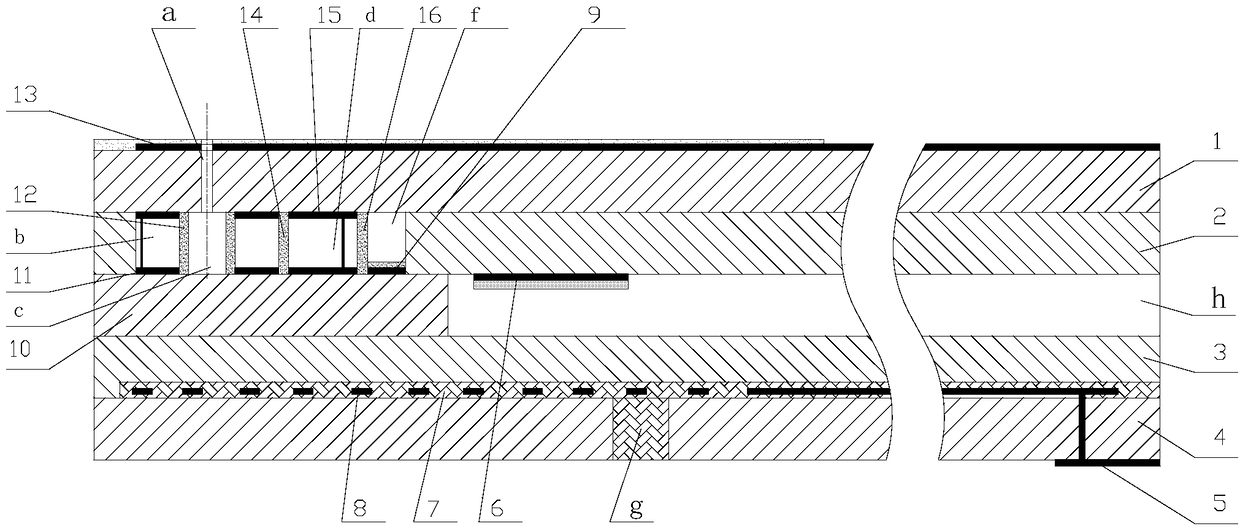

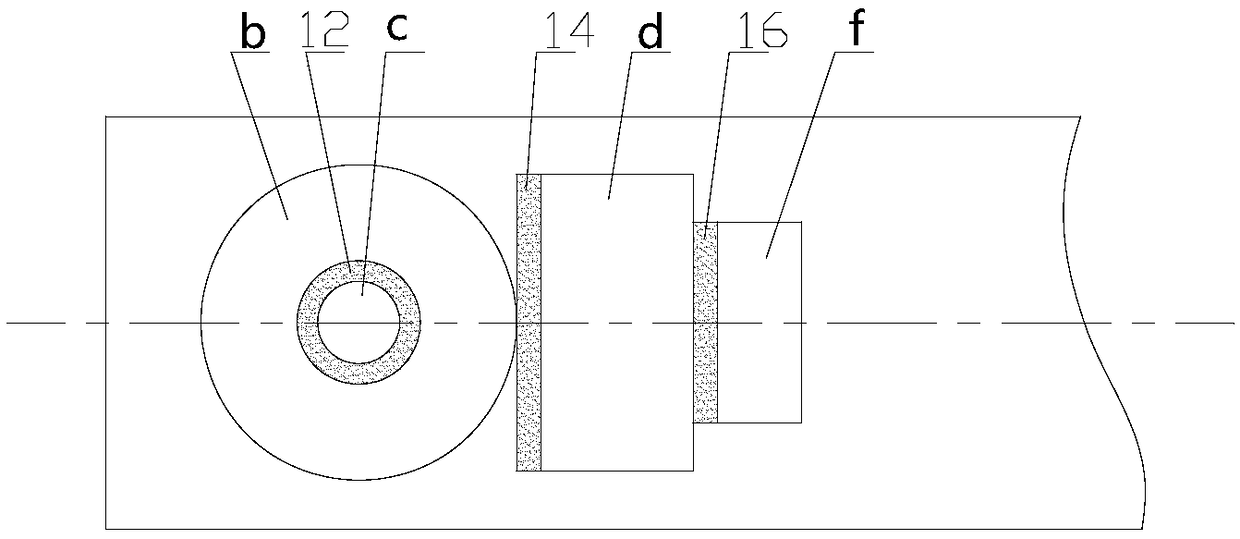

[0017] exist figure 1 , 2 Among them, a nitrogen oxide sensor ceramic chip in this embodiment consists of a first layer of diaphragm 1, a second layer of diaphragm 2, a fourth layer of diaphragm 3, a fifth layer of diaphragm 4, an outer lead wire of a heating electrode 5, a reference Specific electrode 6, heating electrode insulating layer 7, heating electrode 8, measuring electrode 9, third layer of diaphragm 10, main oxygen pump negative electrode 11, first diffusion barrier 12, oxygen pump positive electrode 13, second diffusion barrier 14, auxiliary pump The negative electrode 15 and the third diffusion barrier 16 are connected.

[0018]The chip body consists of the first layer of diaphragm 1, the second layer of diaphragm 2, the third layer of diaphragm 10, the fourth layer of diaphra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com