Multilayer synchronous constant pressure pressing machine of high-sensitivity circuit board

A pressing machine and circuit board technology, applied in printed circuit, multi-layer circuit manufacturing, printed circuit manufacturing, etc., can solve the problems of different pressure and time of pressing, failure to press out products, large differences, etc., to achieve pressure Strict and time control accuracy, guaranteed lamination quality and consistency, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

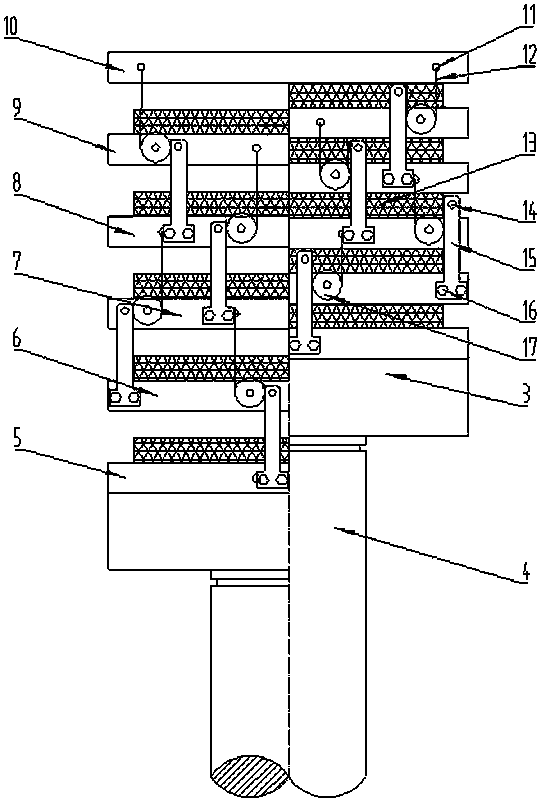

[0011] The present invention will be further clearly and completely described below with specific embodiments in conjunction with the accompanying drawings. Apparently, the described embodiment is only one embodiment of the present invention, rather than all embodiments.

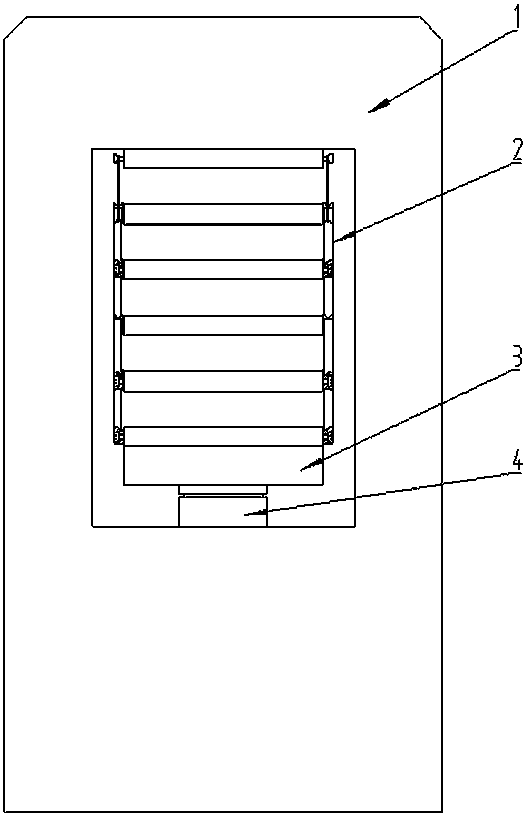

[0012] A high-sensitivity circuit board multi-layer synchronous isobaric pressing machine, which is equipped with a hot plate group simultaneous closing structure 2 on the left and right sides of each layer of hot plates in the traditional pressing machine main frame 1, and the hot plate synchronous closing mechanism is set On both sides of the pressing machine, an oil cylinder plunger 4 is arranged below the main machine frame 1 of the pressing machine and is fixed with the lower backing plate 3 . The static unclosed state in the figure is shown on the left side of the view axis, and the closed state is shown on the right side of the view axis.

[0013] The present invention is provided with six layers of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com