New special skylight glass sealing strip pressing equipment

A technology of skylight glass and special equipment, which is applied in the field of auto parts manufacturing, can solve problems such as water leakage, and achieve the effects of improving durability, ensuring pressing quality, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

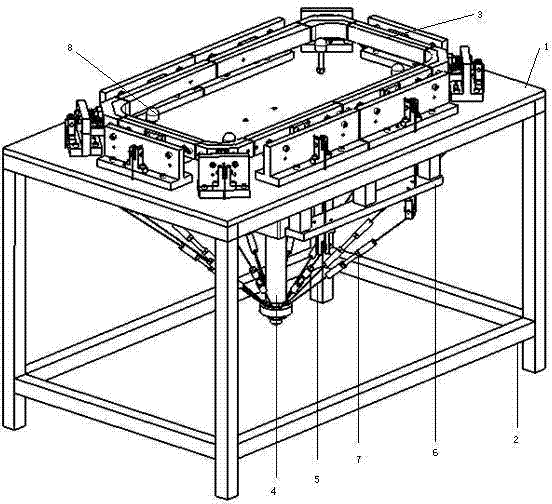

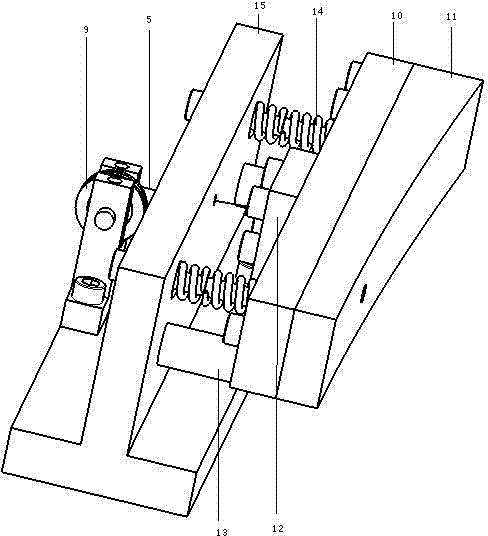

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , the special equipment for press-fitting the novel skylight glass sealing strip of the present invention includes a workbench 1, a bracket 2, a glass leg 8, a cylinder 4, a steel wire 5, a steel wire support 6 and a press-fit module 3, and there is one cylinder 4, which is located on the workbench 1 Below, one end of the steel wire 5 is connected to the cylinder 4, and the other end is connected to the pressing module 3 through the steel wire support 6. This new type of special equipment for pressing the sealing strip of the skylight glass has 10 sets of pressing modules 3, and each long side has two sets of pressing modules. Each short side of the modules 3 has a set of pressing modules 3 , and each corner has a set of pressing modules 3 . When operating, start the cylinder, which drives the steel wire to pull the pressing block backward, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com