Compound pressing roller mechanism of novel coating machine

A pressing roller mechanism and coating machine technology, applied in the field of coating machines, can solve the problems of complex structure, bending and deformation of rubber pressing rollers, affecting the pressing quality, etc., to meet development requirements, large pressing force, and ensure pressing quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

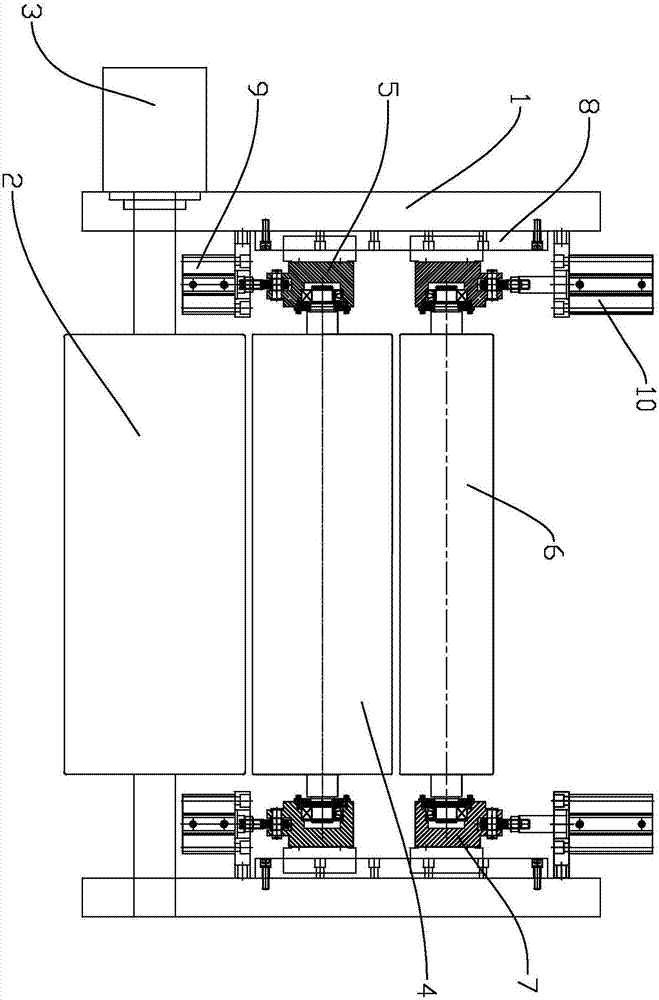

[0019] Reference figure 1 , The present invention is a new type of composite pressing roller mechanism of a coating machine, including:

[0020] Rack 1;

[0021] The composite roller 2 is rotatably installed on the frame 1. The composite roller 2 is preferably driven by a motor 3. Of course, the composite roller 2 can also be driven by other structures, such as hydraulic pumps;

[0022] The pressure roller 4 is rotatably mounted on both ends of the first sliding seat 5, and the first sliding seat 5 is slidably installed on the frame 1. The pressure roller 4 is preferably made of rubber;

[0023] The back pressure roller 6 is rotatably mounted on a second sliding seat 7 at both ends, and the second sliding seat 7 is slidably installed on the frame 1. The back pressure roller 6 is preferably made of steel;

[0024] The composite roller 2, the pressure roller 4 and the back pressure roller 6 are arranged in parallel, and the pressure roller 4 is located between the composite roller 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com