The method of guaranteeing the pressing quality of special-shaped parts in the forming process

A special-shaped part and molding process technology, which is applied to tires, household appliances, and other household appliances, etc., can solve the problems of uniformity fluctuation of tire service life, impact on consumer use, and difficulty in pressing quality, so as to ensure compliance, The effect of reducing early quality problems in the market and avoiding abnormal material deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

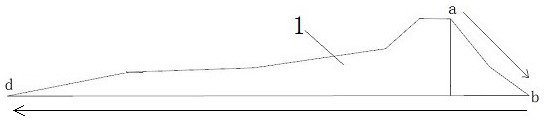

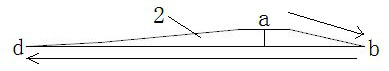

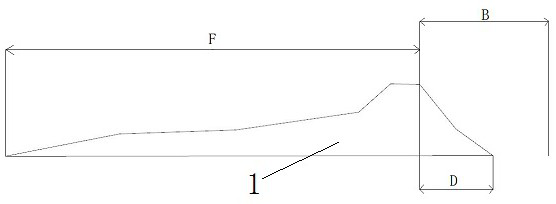

[0030] The present invention provides a method for ensuring the pressing quality of special-shaped parts in the molding process. Figure 1-2 a point in ), the inner endpoint ( Figure 1-2 point b in ) to the outer endpoint ( Figure 1-2 d point) in the order of pressing.

[0031] During the pressing process of the rubber pad part 1 and the sidewall part 2 on the drum, the lower pressing roller is pressed outward in the axial direction when the drum rotates. At this time, the track of the pressing roller on the pressed part is in a spiral shape. Due to the irregular shape of the cushion rubber part 1 and the sidewall part 2, the outward thrust generated by the pressing roller during the pressing process is obviously greater than that when the components are fitted due to the change of the thick and thin points of the components and the helical pressing track. Adhesion, resulting in localized misalignment of parts when pressed together. The thickest point of the part is used ...

Embodiment 2

[0046] On the basis of Example 1, it also includes the confirmation of the lower rubber core part 3 after pressing: the structure of the lower rubber core part 3 before pressing is as follows: Figure 5 As shown, the structure after pressing is as follows Image 6 Set the width of the lower rubber core part 3 after pressing, move the positioning laser light mark to the set position according to the width, and measure the distance between the outer thinnest end point of the lower rubber core part 3 and the positioning laser light mark If the distance meets the preset standard 2, it is determined that the lower rubber core part 3 meets the requirements for pressing; if the distance does not meet the preset standard 2, the lower rubber core part 3 is re-pressed after adjusting the pressing parameters. Wherein, the second preset standard is: distance≤10mm.

[0047] By the method of this embodiment, the pressing quality of the lower rubber core part 3 during the pressing process c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com