High-supersonic-speed internal contraction air intake channel gradually changed from convex shape into round shape and design method thereof

A hypersonic, design method technology, applied in mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve the problems of loss of flow, low efficiency, etc., to solve the problem of starting, prevent the congestion of the throat, and reduce the self-starting Mach number. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

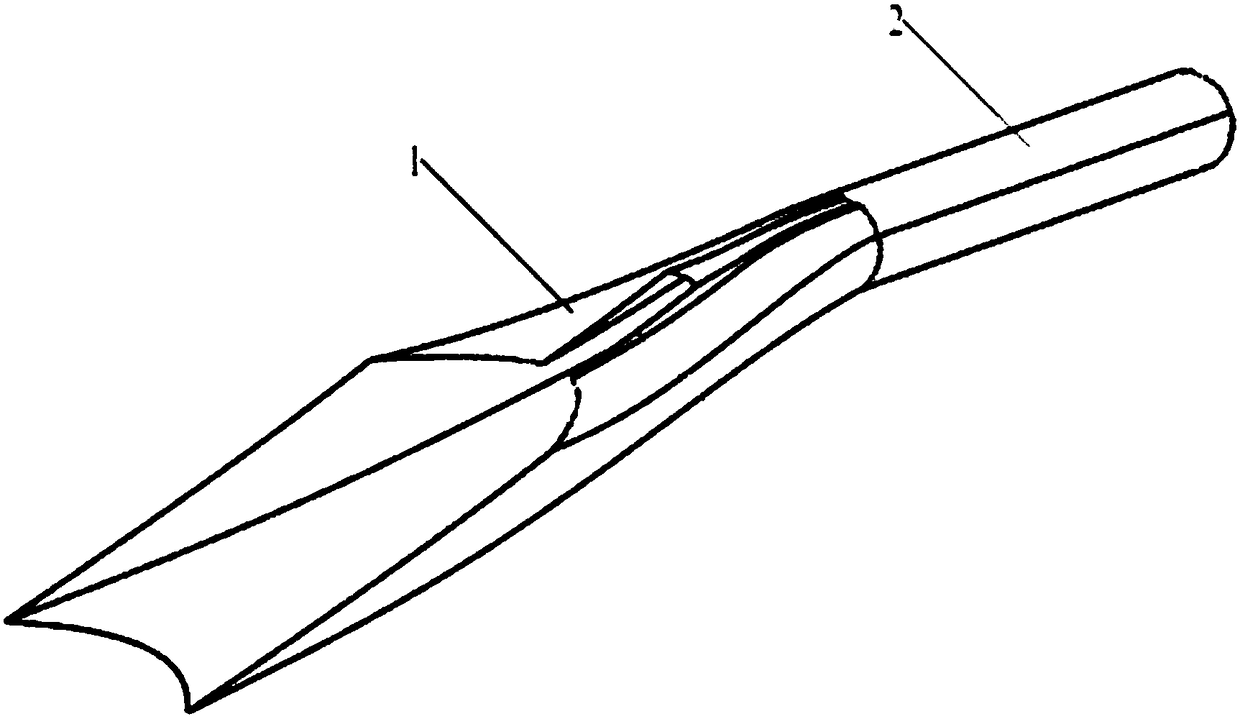

[0028] Such as figure 1 , 2 , 3 and 4 show a hypersonic convex-turned-circular inner constriction inlet, including a convex-turned-circular inlet 1 and a circular equal straight isolation section 2;

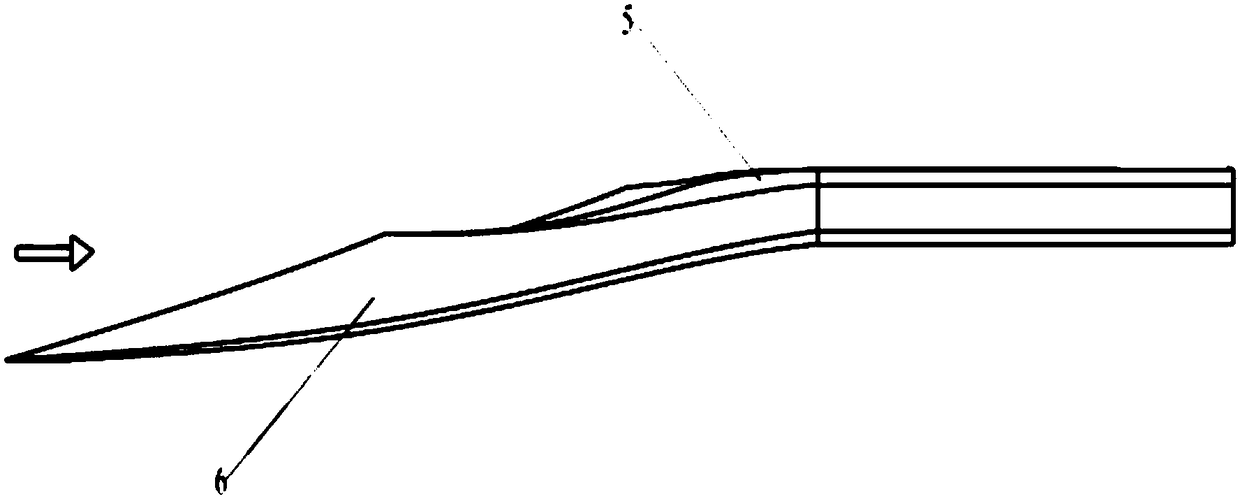

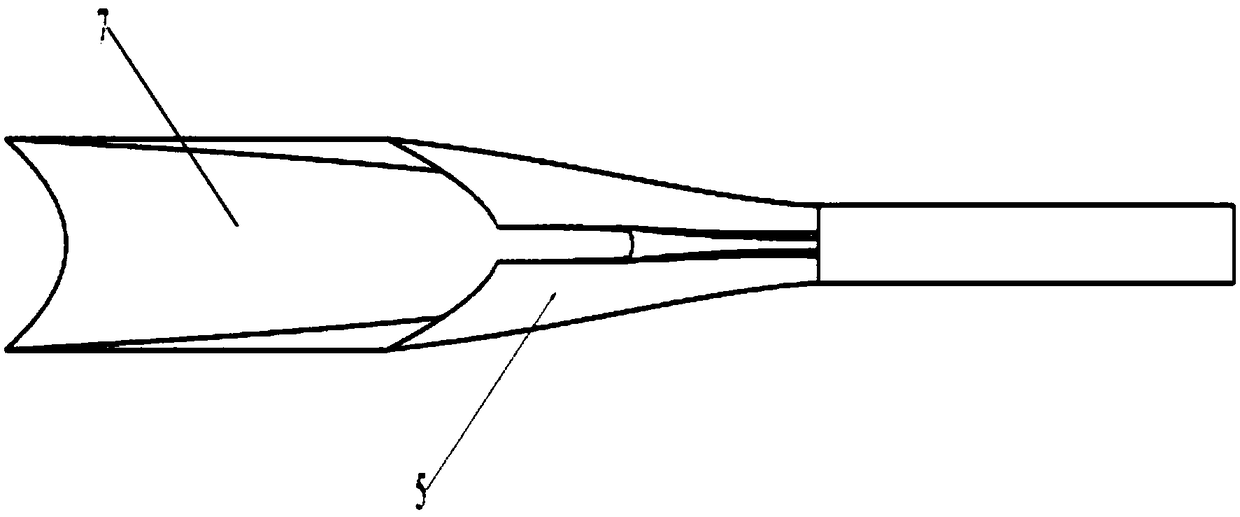

[0029] Wherein, the convex-turned circular air intake 1 includes an air intake lip plate 5, an air intake side plate 6 and an air intake top plate 7, and the middle part of the air intake lip plate 5 is provided with an upward convex portion; The entrance shape of the convex-to-circular air inlet 1 is similar to a convex shape, and shrinks toward the exit to gradually become a circle, and then connects with a circular and straight isolation section 2 of equal area.

[0030] Such as Figure 5 , 6 Shown is a design method for a hypersonic convex-to-circular inner constriction inlet. The inlet capture surface is a convex shape composed of "rectangular + upward convex slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com