Patents

Literature

122results about How to "Flat and beautiful appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

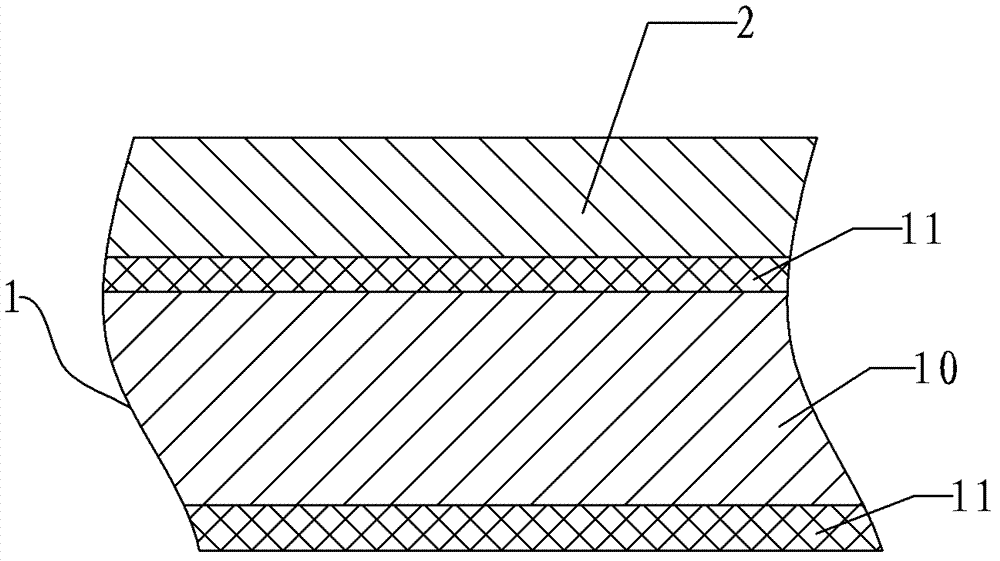

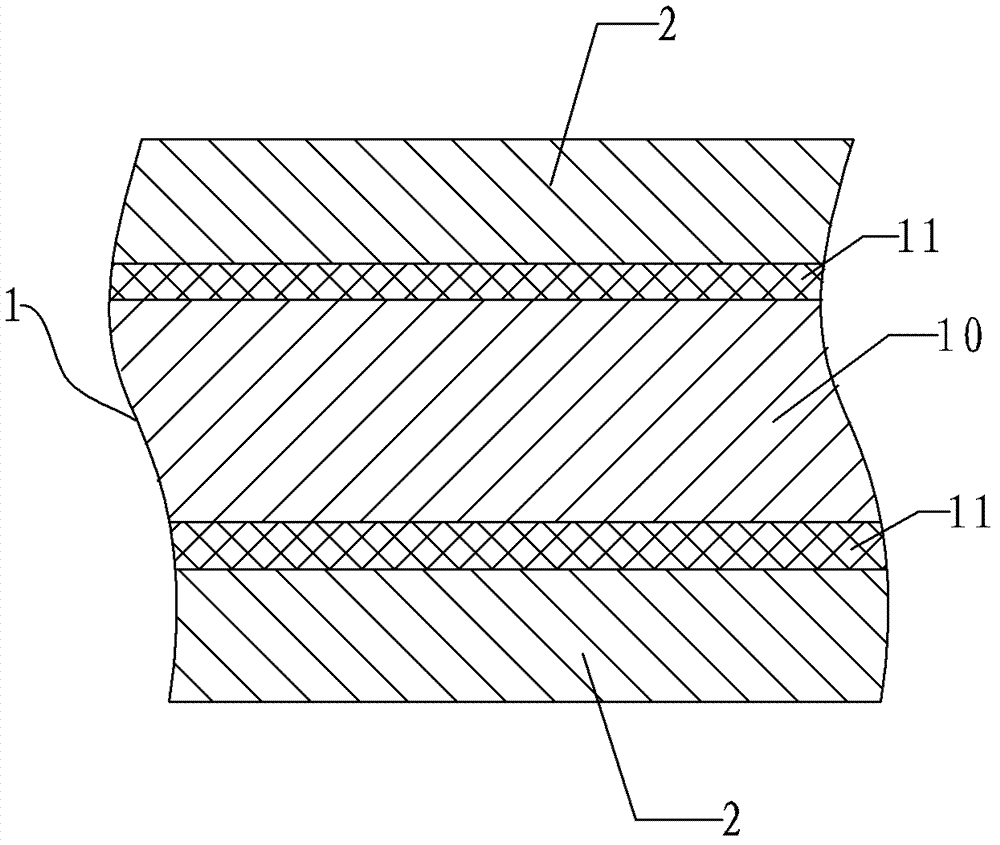

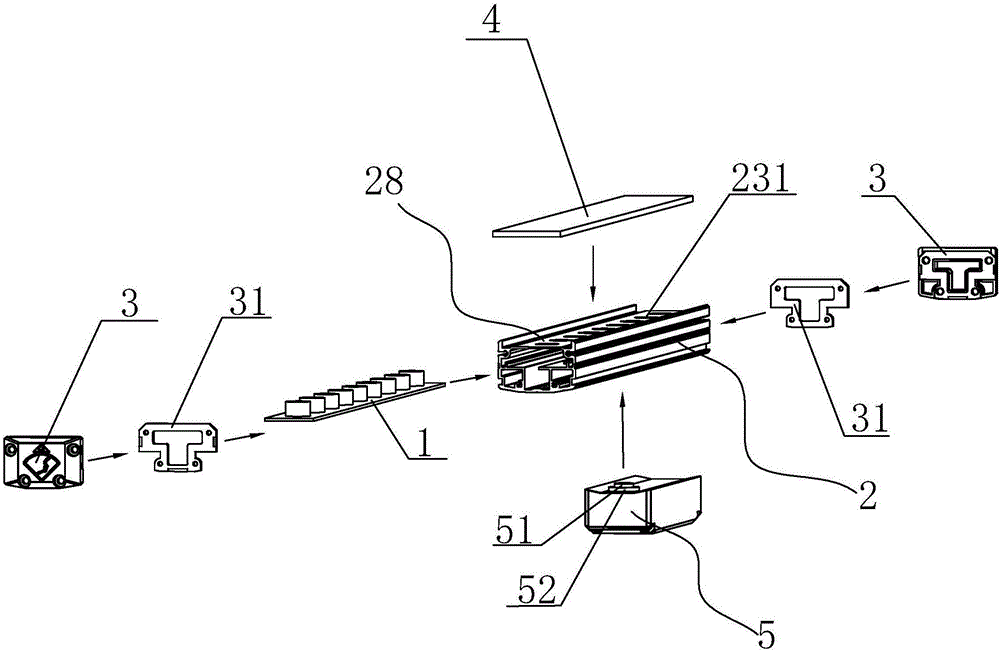

A continuous composite molding lightweight photovoltaic module and its continuous composite molding equipment

ActiveCN110491961BGuarantee the quality of laminationImprove yield rateFinal product manufacturePhotovoltaic energy generationBattery cellMaterials science

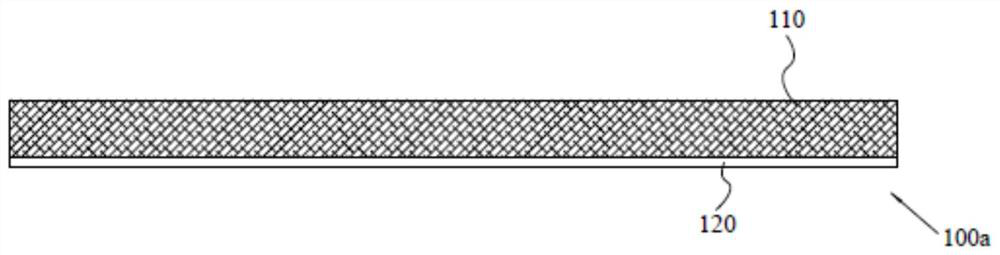

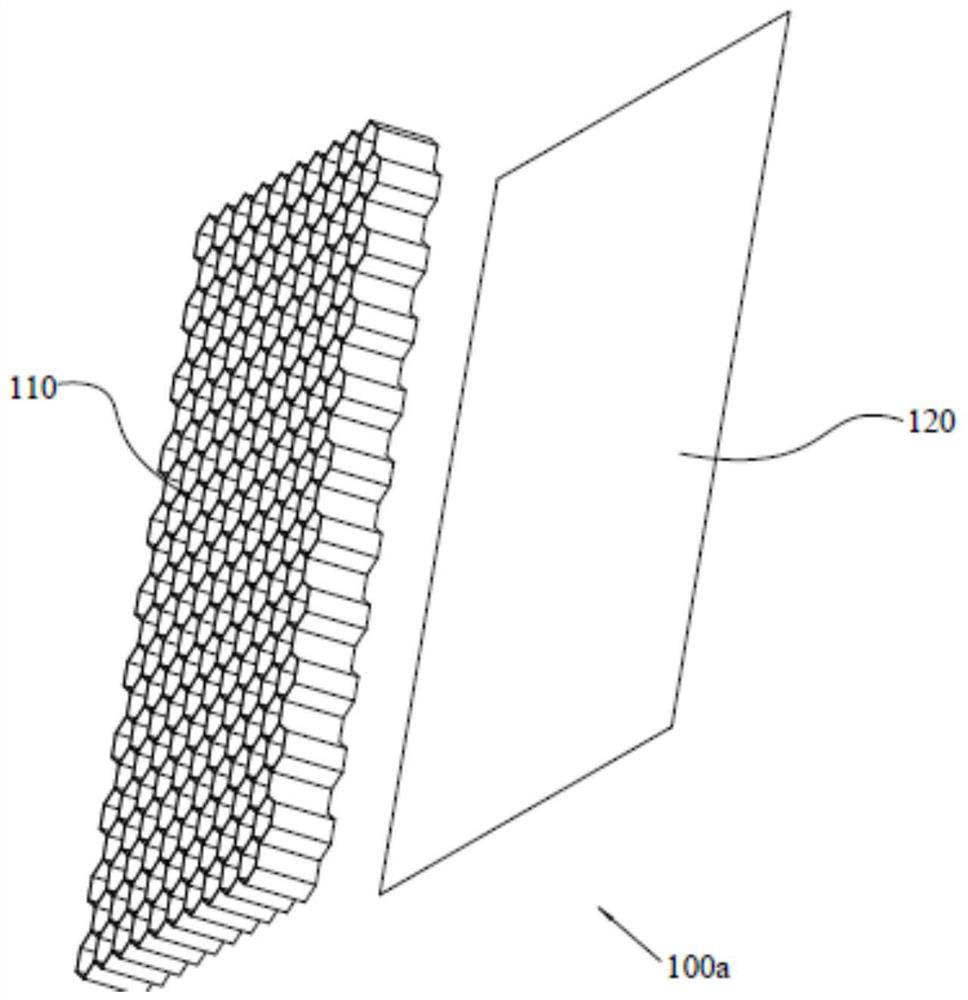

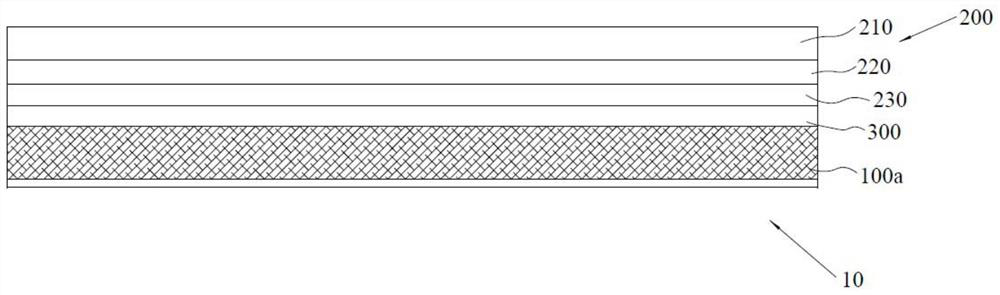

The invention discloses a continuous composite molding lightweight photovoltaic module, which includes a photovoltaic laminate and a lightweight photovoltaic backplane. The photovoltaic laminate includes a front flexible packaging layer, a battery sheet layer, and a back flexible packaging that are laminated and packaged as one. layer, the lightweight photovoltaic backplane includes at least a thermoplastic core layer in the shape of a honeycomb or porous foam and a first thermoplastic substrate layer, and the photovoltaic laminate and the lightweight photovoltaic backplane are composited into one body through a continuous composite molding process; The invention also discloses continuous composite molding equipment; the invention also has the advantages of light weight, safety and reliability, frameless design is not easy to accumulate dust and does not need to be grounded, and its layout can be flexible and changeable, avoiding the high burst problem of traditional double glass components, Moreover, the present invention will not cause problems such as bubbling, degumming, deformation and creep under the lightweight photovoltaic backplane scheme using the adhesive film layer structure, and will not be limited by the thickness of the light photovoltaic backplane, which fully meets the requirements of photovoltaic standards. , can realize real-scale promotion and application.

Owner:SUNMAN (ZHENJIANG) CO LTD

Silicon dioxide reinforced PA66 and preparation thereof

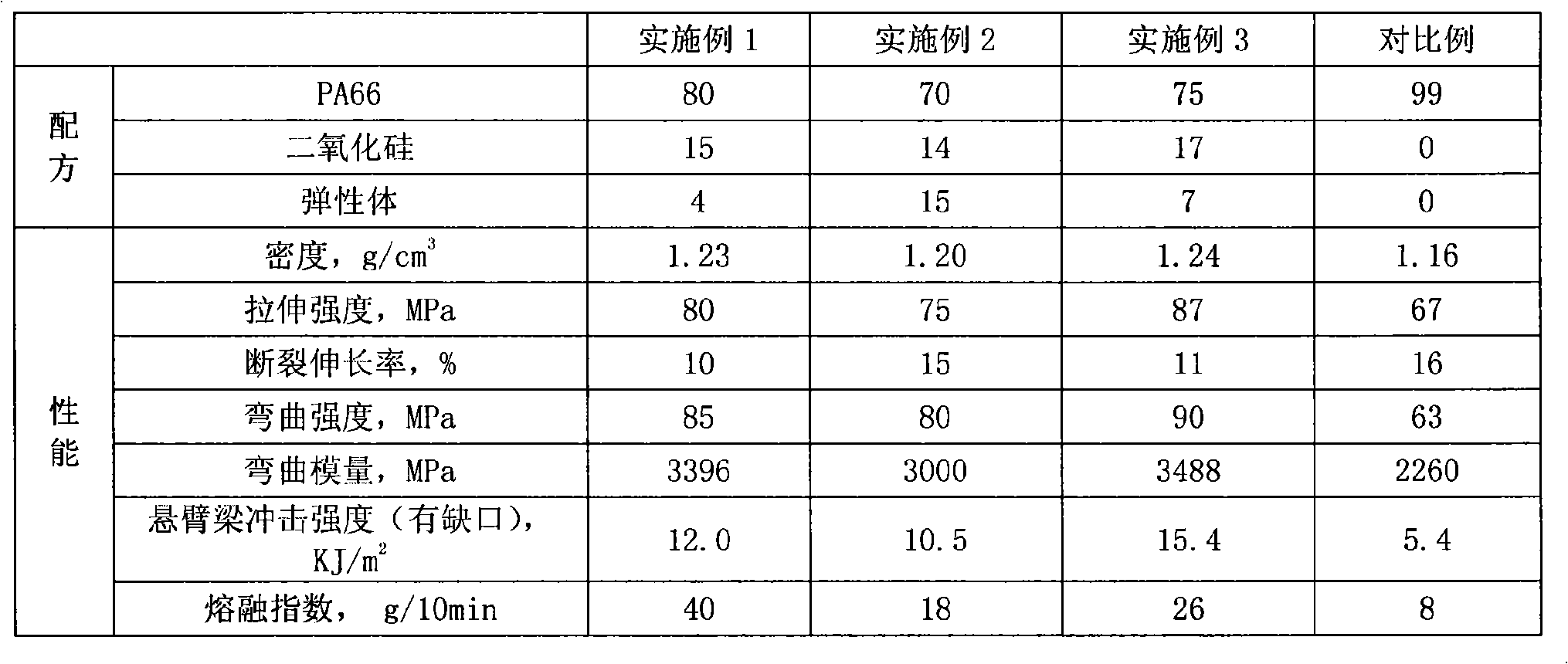

The invention relates to a silica reinforced PA66 and a preparation method thereof, the raw materials of which include following materials by weight: 70-80 portions of PA66, 13-17 portions of silica, 4-15 portions of elastomer, 0.1-0.3 portion of coupling agent, 0.2-0.5 portion of antioxidant, and 0.5-1 portion of lubricant. The preparation method is as follows: (1) prepare high filling base material by extruding pelletizing after the silica, the coupling agent, the antioxidant, the lubricant and the PA66 are uniformly mixed, wherein, the weight ratio of the PA66 to the silica is from 45: 55 to 60: 40, with the amount of the lubricant being 0.5 to 1 percent of the gross weight of the PA66 and the silica; (2) carry out the extruding pelletizing after the high filling base material is uniformly mixed with the elastomer, the residual PA66 and the lubricant. By well combining rigidity, flexibility and fluidity, the invention can be used for machining large-sized plastic pieces, and further enlarging the application scope of the PA66.

Owner:NANJING HONGRUI PLASTIC PROD

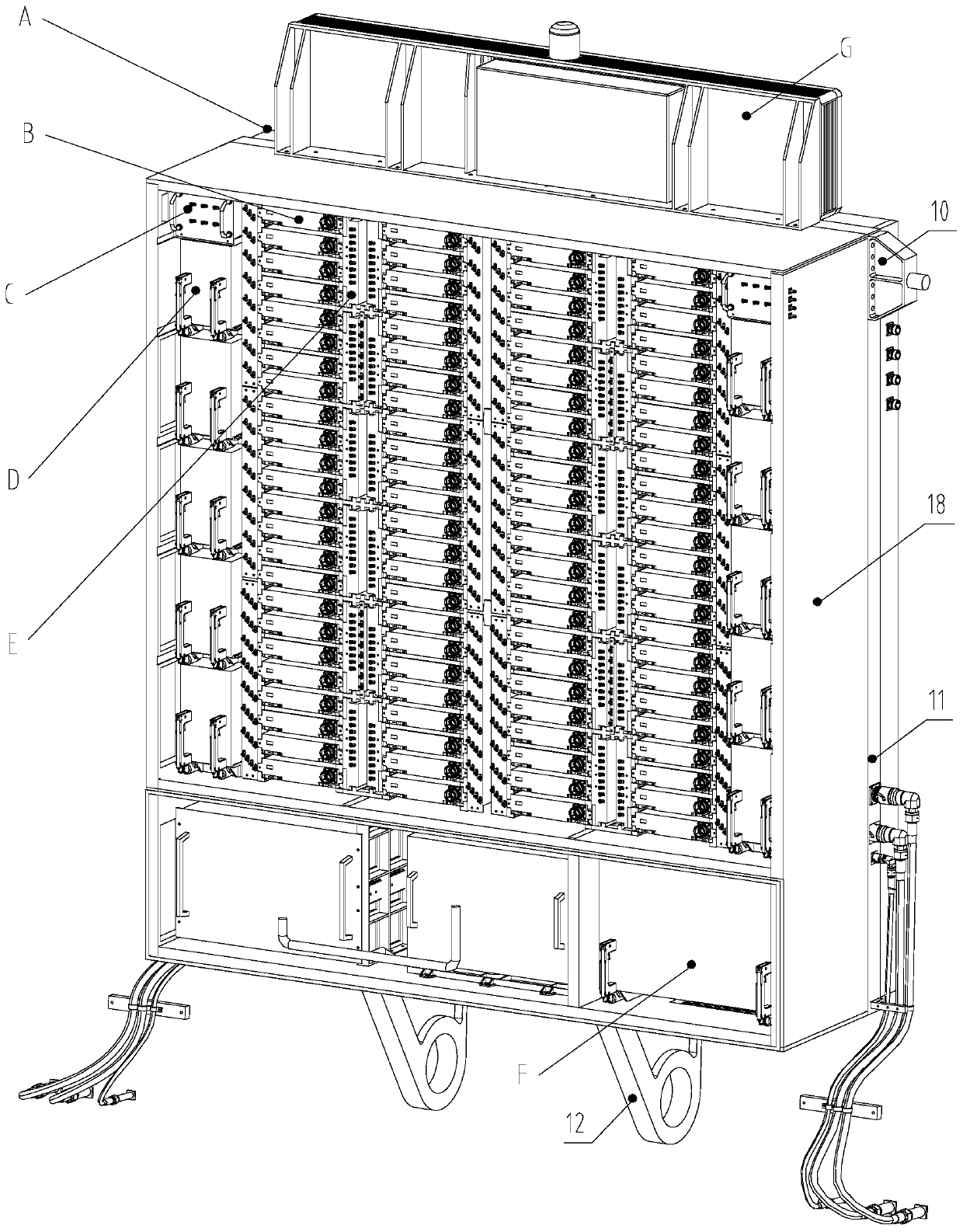

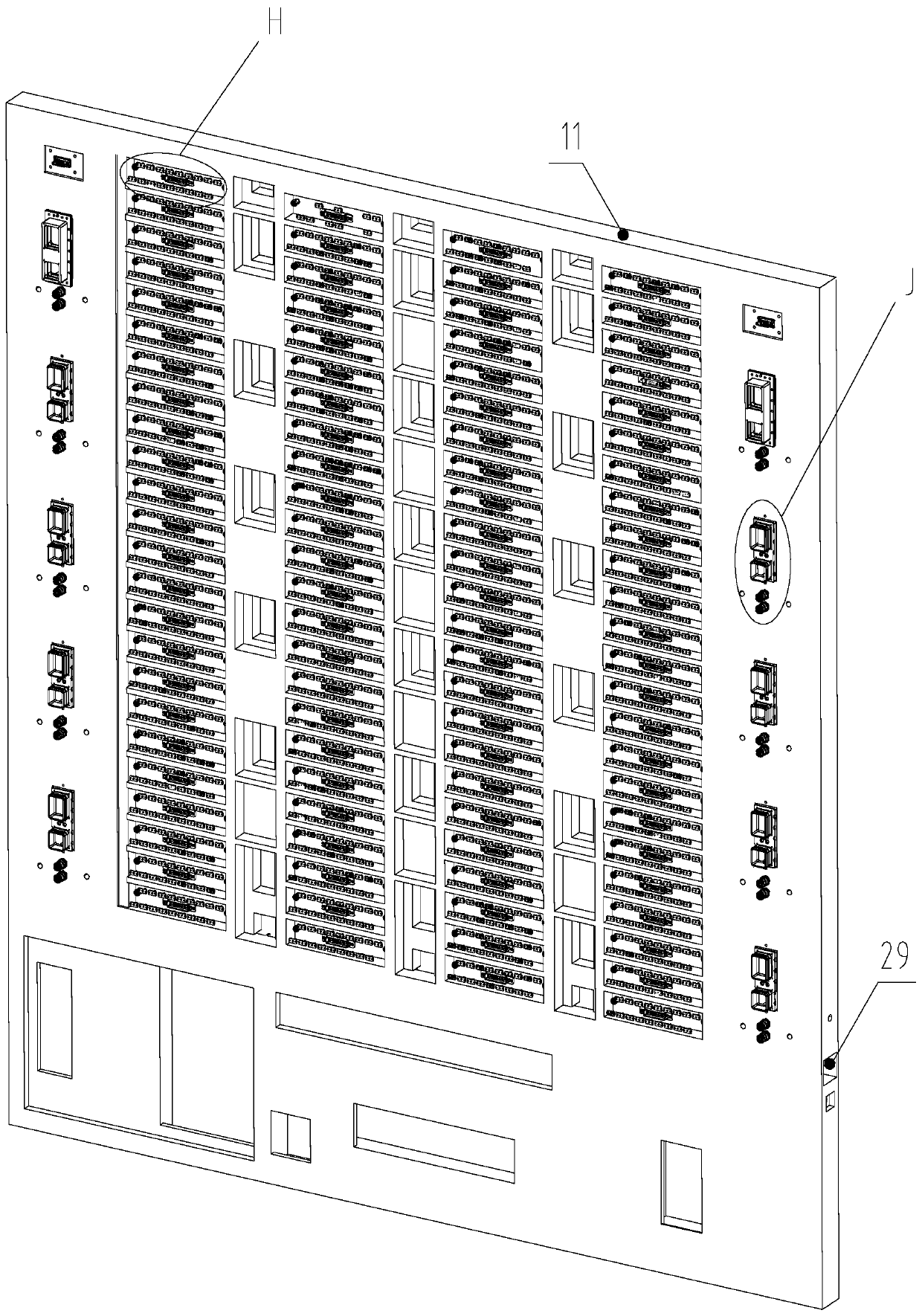

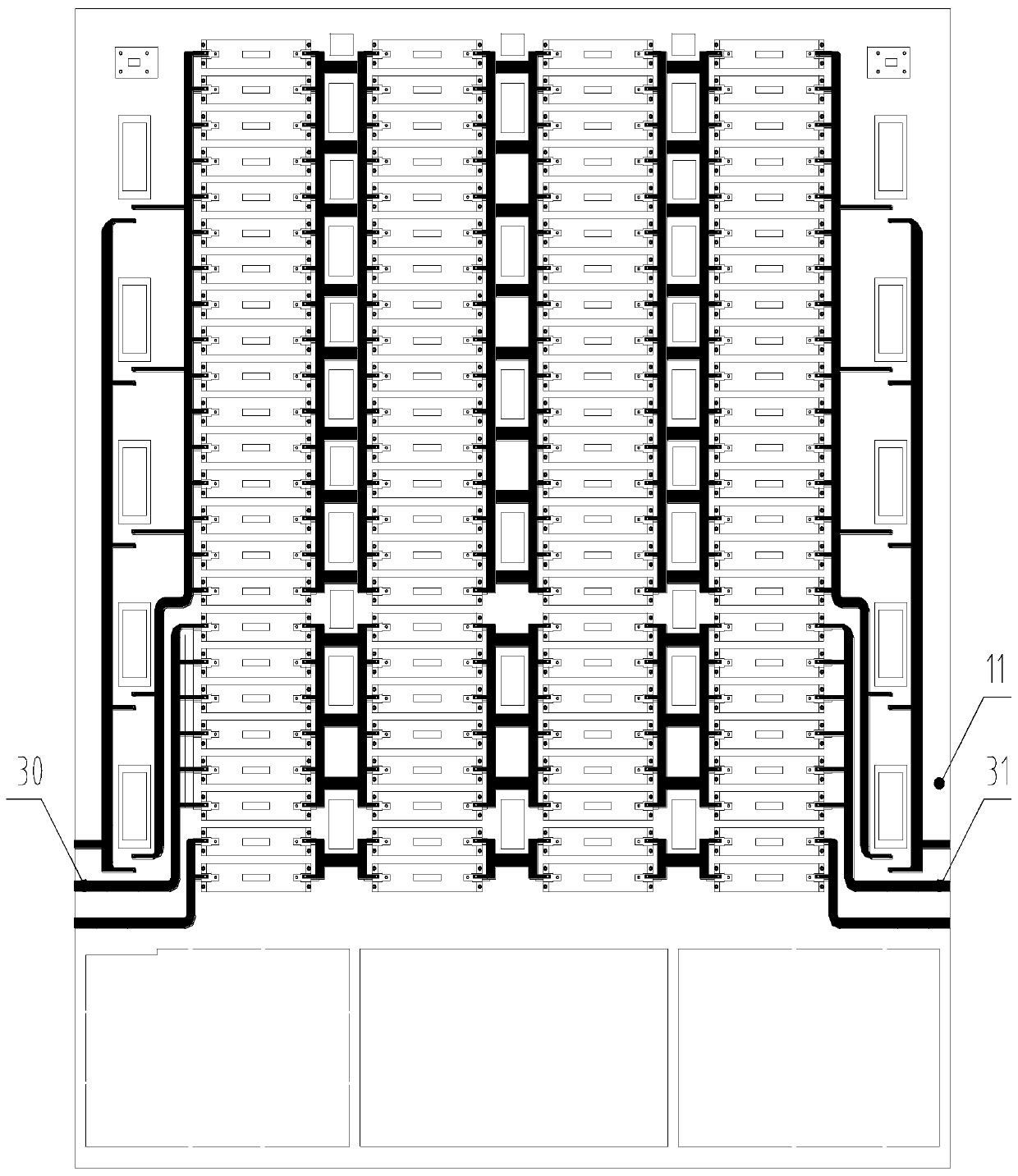

High-integration lightweight array radar antenna skeleton

ActiveCN110265764AReduce weightHigh precisionAntenna supports/mountingsDe-icing/drying-out arrangementsMaintainabilityRadar

The invention relates to the field of radar antenna vehicles and particularly relates to a high-integration lightweight array radar antenna skeleton. An outer frame is arranged around a backplane. A liquid cooling water channel is arranged inside the backplane. The backplane is formed by an aluminum plate through primary processing. A coolant enters the backplane from a liquid inlet and exits from a liquid outlet. A plurality of liquid-cooled blind-mate plugs are arranged on the backplane. An antenna longitudinal rib plate, an antenna transverse rib plate, and an antenna unit mounting slot are disposed inside the outer frame. A cavity portion in the outer frame on the front side of the backplane divides the space inside the outer frame into electronic compartments by the antenna longitudinal rib plate and the antenna transverse rib plate. The lower space in the outer frame is provided therein with an extension compartment. The upper space in the outer frame is provided therein with a component compartment. The cavity portion in the outer frame on the back side of the backplane is provided therein with the antenna unit mounting slot. The antenna skeleton assembly of the invention has the characteristics of compact and reasonable layout, high integration, reliable structure, low weight, good rigidity, high precision, good maintainability and fast heat dissipation.

Owner:WUHAN BINHU ELECTRONICS

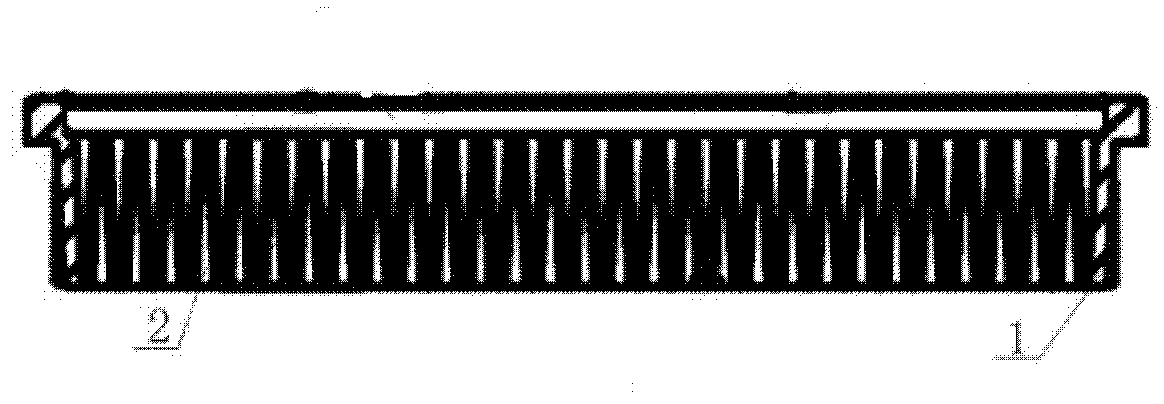

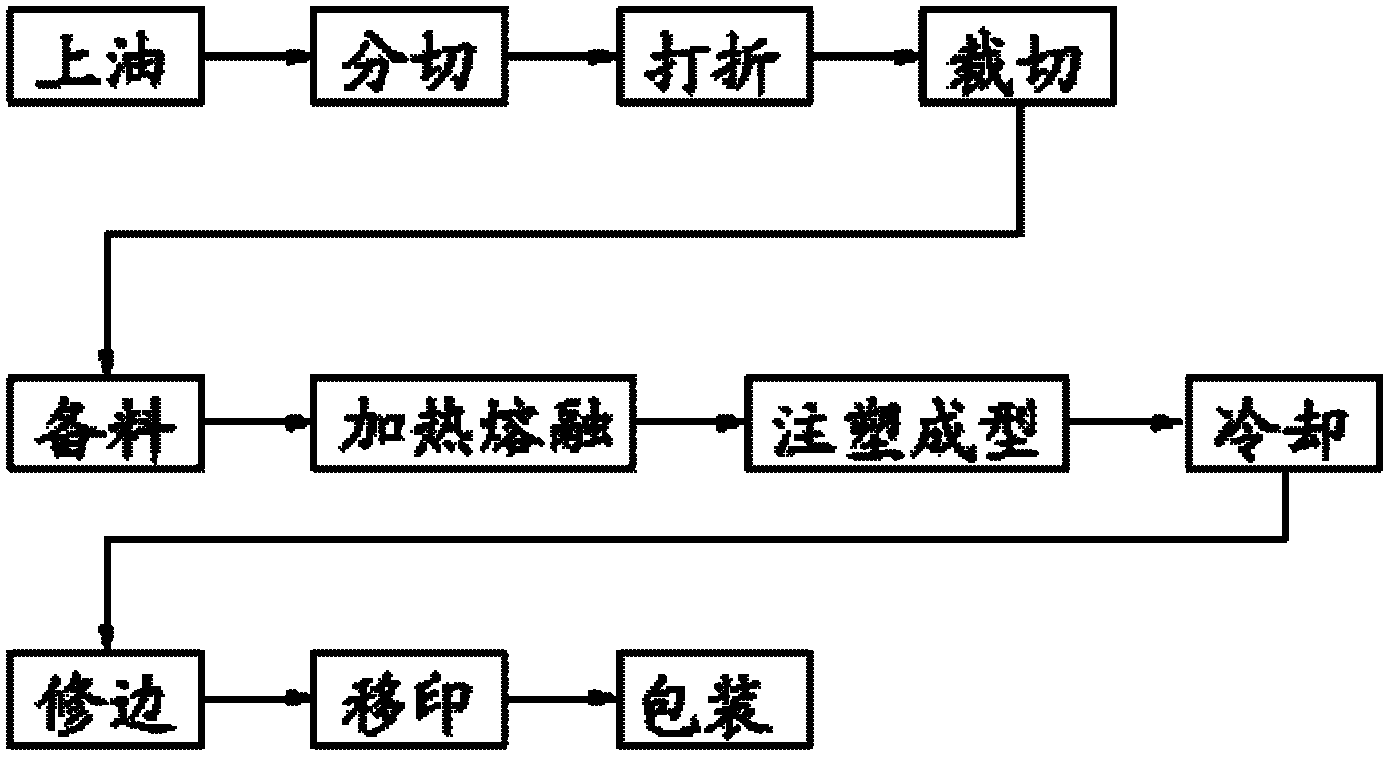

Air filter and preparation process thereof

InactiveCN102631816AEasy to separateGood sealing effectDispersed particle filtrationCombustion-air/fuel-air treatmentCombustionForming processes

The invention provides an air filter which comprises a fixed frame and a filter element, wherein the peripheral edges of the filter element are embedded into a frame body of the fixed frame; the fixed frame is made of a thermoplastic elastomer (TPE); the filter element is nonwoven cloth; and the fixed frame and the filter element are integrated through an insert forming process. The invention also provides a preparation method for the air filter. The preparation method comprises the following steps of preparing the filter element, forming inserts and treating after forming. According to the air filter and the preparation method thereof, the air filter is high in sealing property, large in ventilating amount and flat and attractive in appearance, can be recycled and degraded and is particularly suitable for automobile engines, so that the combustion efficiency and the power of the engine are improved effectively.

Owner:HKR SPECIALTY EQUIP +1

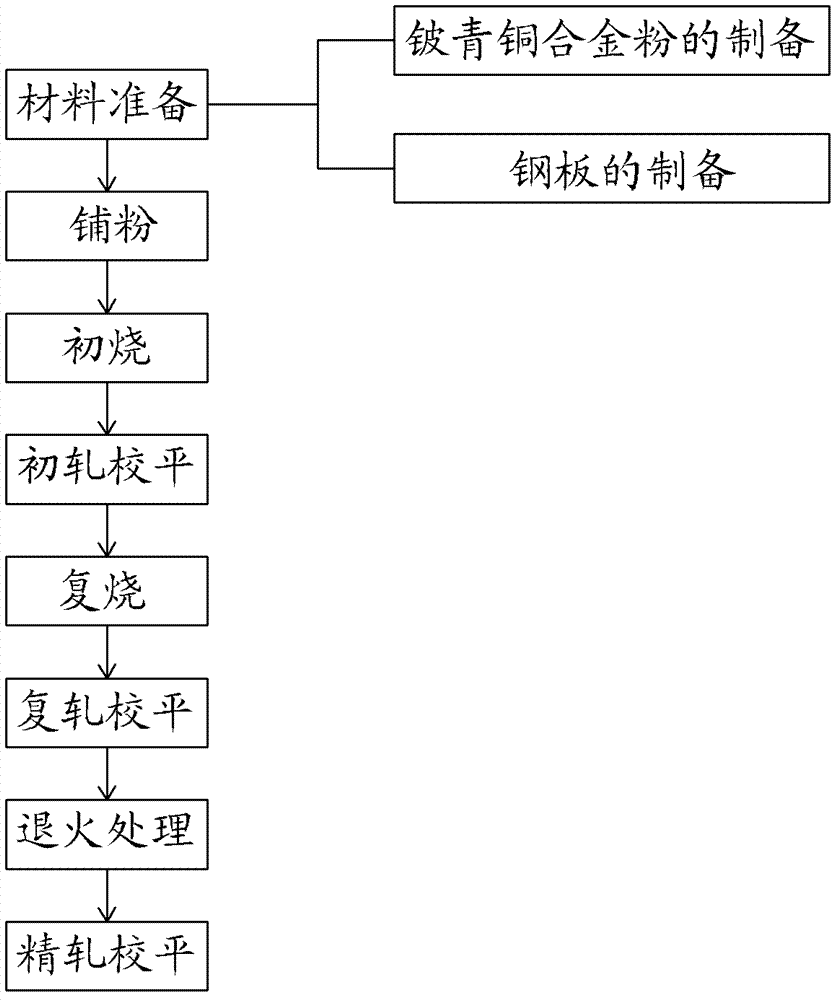

Easily-molded environment-friendly beryllium bronze-steel bimetallic bearing material and manufacturing method thereof

ActiveCN102848634AImprove bindingImprove carrying capacityFurnace typesHeat treatment furnacesAlloyCopper

The invention provides an easily-molded environment-friendly beryllium bronze-steel bimetallic bearing material which is suitable for manufacturing bearing shells, bushes, flanges and the like in large-power high-rotating speed automobile engines, and is sintered by a steel plate layer and an alloy layer; the steel plate layer and the alloy layer are an upper layer and a lower layer, or an inner layer and an outer layer; the steel plate layer comprises a steel plate at a base layer and a copper-plated layer on the steel plate surface; the steel plate material is low-carbon high-quality carbon steel with a carbon content of less than 0.2%; the thickness of the copper-plated layer is 0.30-1.00 mm; the alloy layer material is beryllium bronze alloy powder; the beryllium bronze alloy powder comprises the following chemical components by weight: 2-5% of beryllium, 5-7% of tin, 7-8% of zinc, and the balance of copper; and the particle size of the beryllium bronze alloy powder is less than 0.1 mm. The invention also provides the manufacturing method of the easily-molded environment-friendly beryllium bronze-steel bimetallic bearing material.

Owner:江苏联其材料科技有限公司

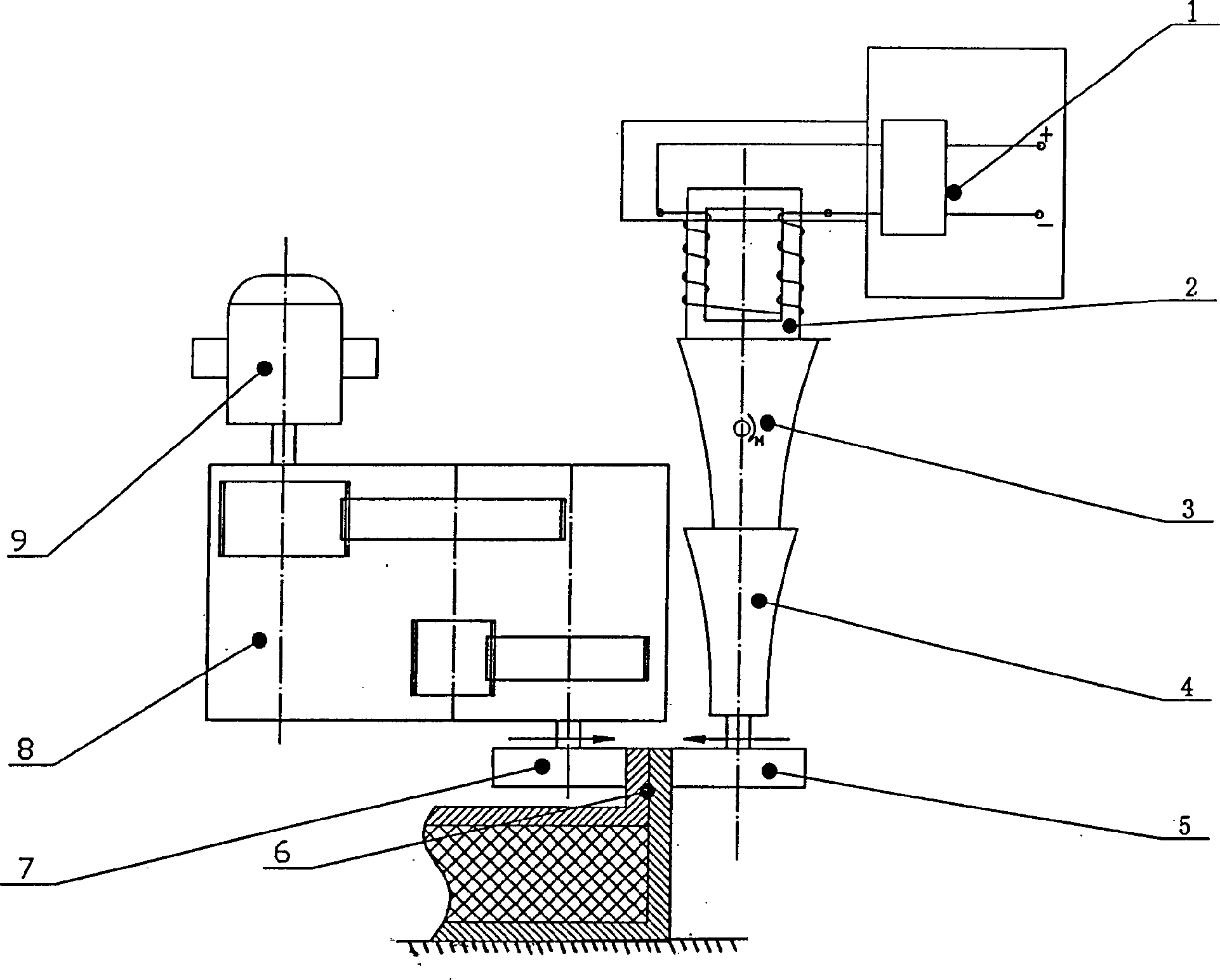

Ultrasonic roll welding device

InactiveCN1803446ASeamlessEasy to recycleMechanical vibrations separationNon-electric welding apparatusUltrasound deviceAdhesive

The invention discloses an ultrasonic roll-welding device, which comprises the following parts: ultrasonic equipment within ultrasonic generator, energy converter, fixation rod and amplitude rod, welding rolling wheel, reflective rolling wheel, decelerator and servo motor, wherein the rear end of amplitude rod extends a segment of shaft to match the welding rolling wheel; the output shaft of servo motor connects the input end of decelerator and the output end of decelerator matches the reflective rolling wheel; the workpiece is placed on the working bench with the reflective rolling wheel and welding rolling wheel compact the edge of workpiece. The invention can weld the plastic panel and edge of plastic floor directly, which is convenient to recover.

Owner:ZHEJIANG UNIV

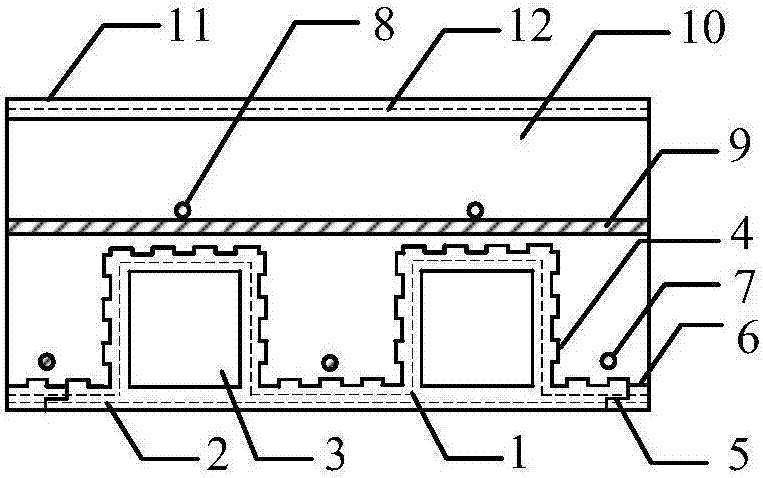

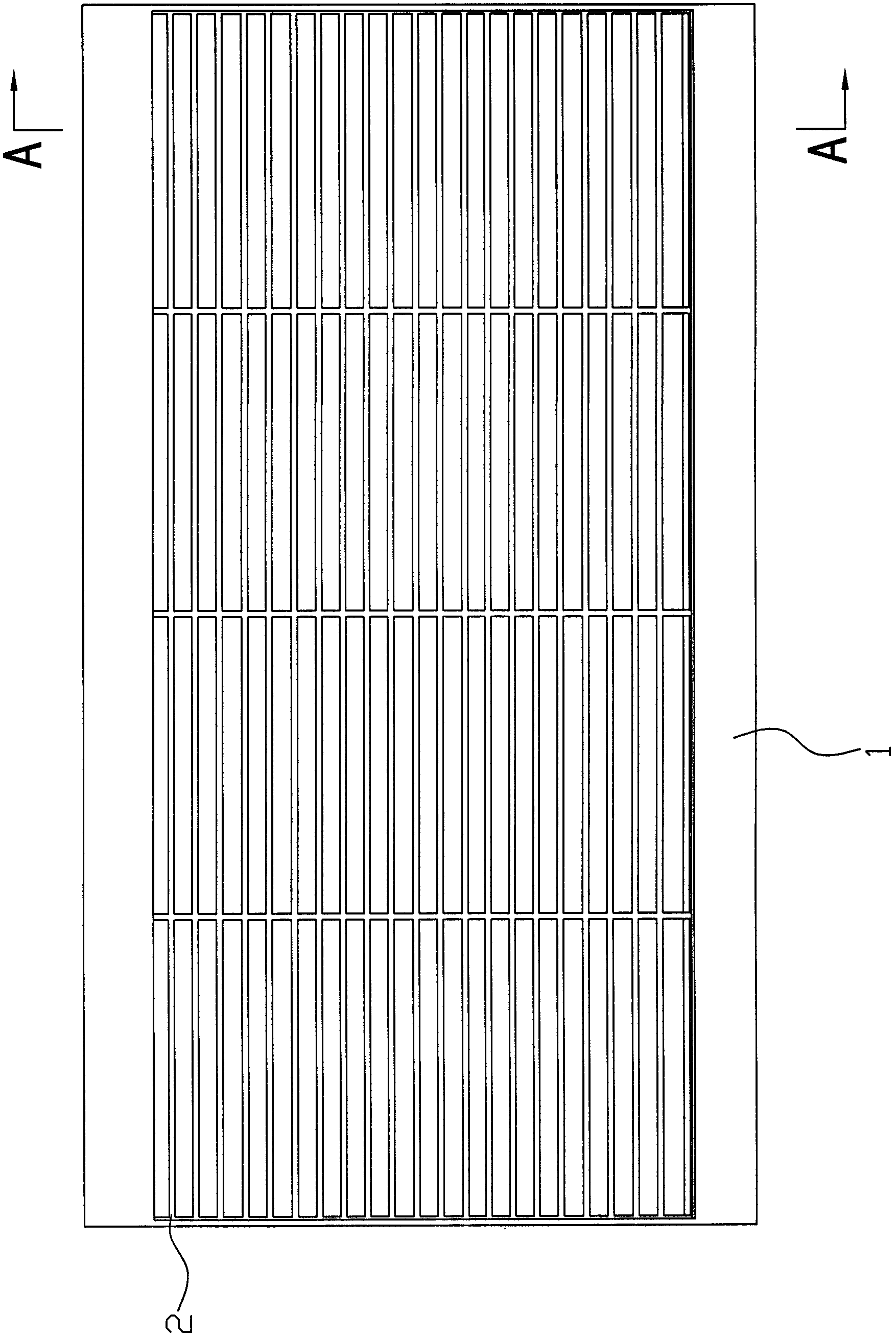

Reinforcement type textile concrete floor and manufacturing method and installing method thereof

The invention provides a reinforcement type textile concrete floor and a manufacturing method and an installing method thereof. The reinforcement type textile concrete floor comprises a prefabricated multi-cavity textile concrete sheet, a fine stone reinforced concrete reinforcing layer and a waterproof leveling layer. The prefabricated multi-cavity textile concrete sheet is composed of textiles, chopped fibers and mortar. In the installation process, the short span direction of the floor is used as the length direction of the prefabricated multi-cavity textile concrete sheet, the prefabricated multi-cavity textile concrete sheet serves as a floor formwork and can also serve as a lower protection layer and a tension layer of the floor after being subjected to casting molding, the thickness of the protection layer is not limited, the story height is reduced, corresponding loads are borne, the construction cost can be reduced, and the construction progress is accelerated. The floor is high in bearing force, good in durability, good in crack resistance, low in amount of needed concrete and low in cost. The floor casting process is simple, and the construction efficiency is high.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

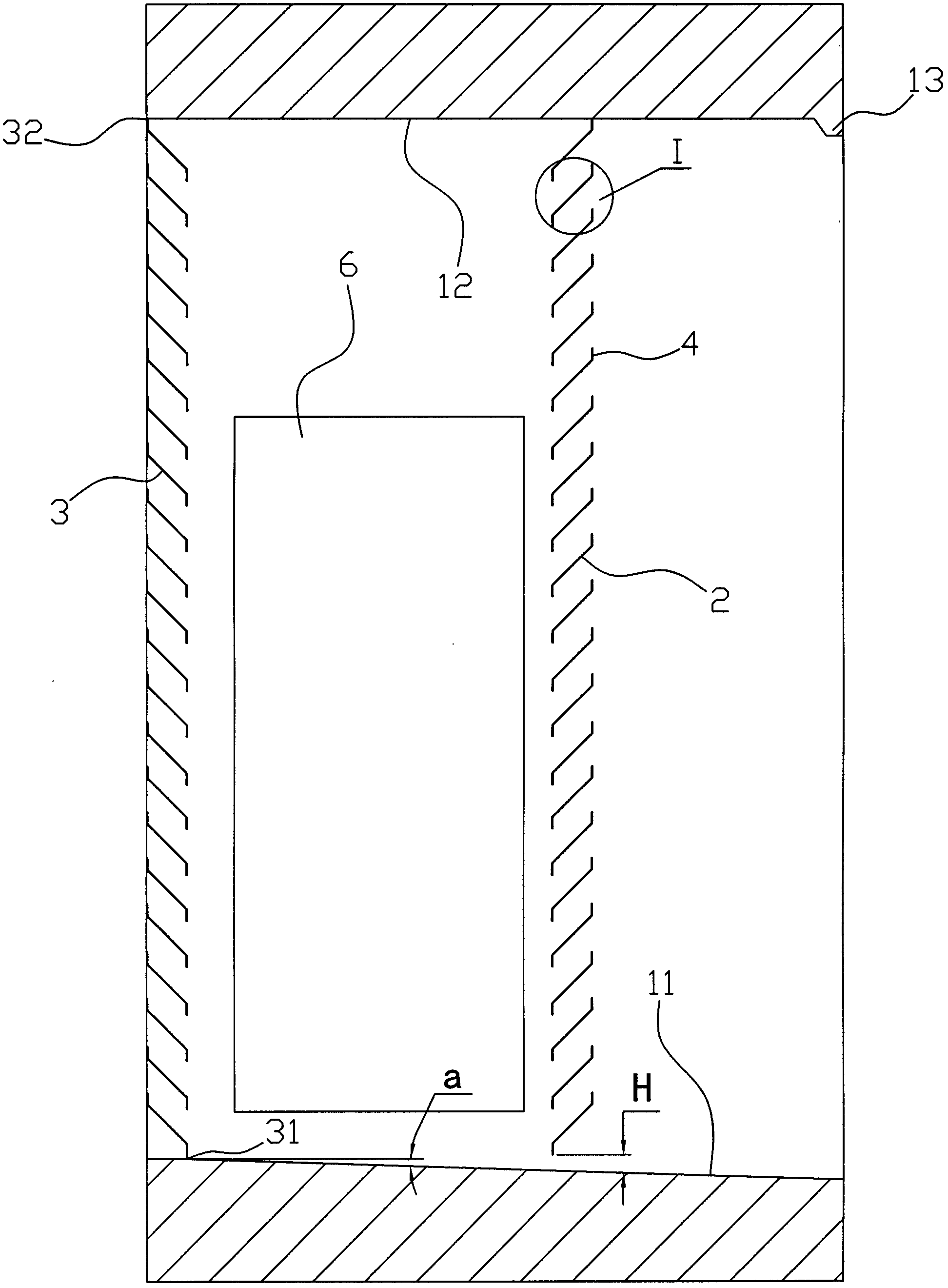

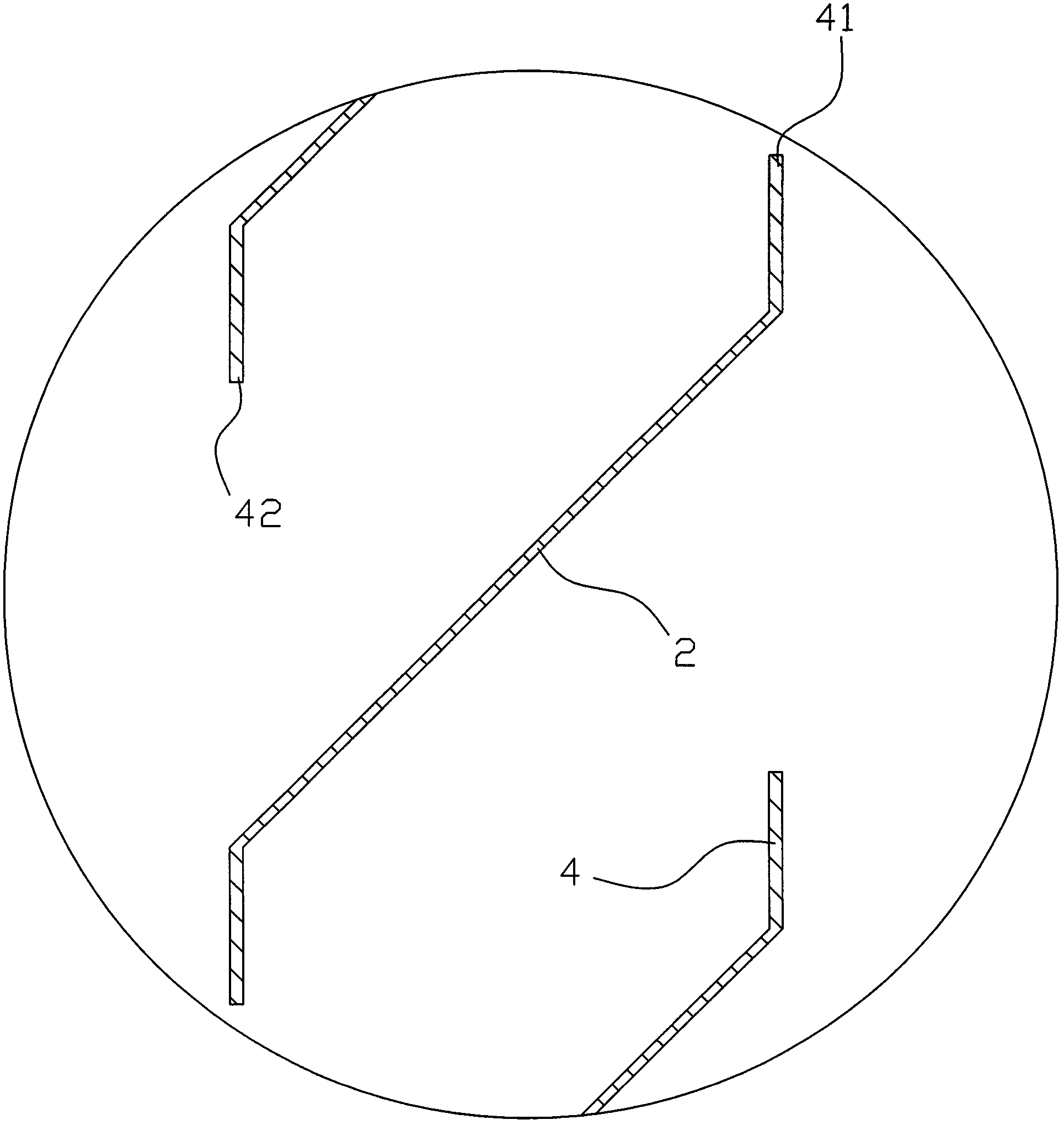

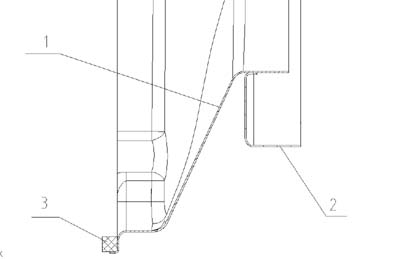

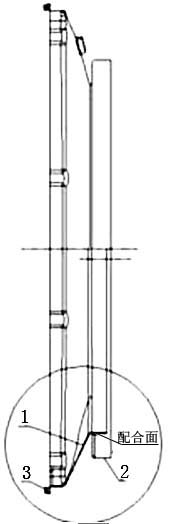

Blind window

ActiveCN103899227AImprove ventilationGood effect against rainwater intrusionCondensed water drain-offWindow shutterAerospace engineering

A blind window comprises blades which are vertically arrayed at intervals in parallel. The blades are obliquely arranged on a window (1). The blind window is characterized in that the blades are arrayed in two layers and are arrayed in the window at intervals in the front-back direction; the blades (2) on the outer layer have high outer sides and low inner sides and are obliquely arrayed together; and the blades (3) on the inner layer have high inner sides and low outer sides and are obliquely arrayed together. The blind window has the advantages that when in a typhoon weather, rainwater blown from the horizontal direction is guided by the blades on the outer layer, drops downwards, then is stopped by the blades, which have the high inner sides and the low outer sides, of the inner layer, and flows out of the window from a lower water draining gap, so that the problem that part of scattered rainwater which is not guided by the blades of the outer layer can penetrate in the blades of the inner layer and then enters an indoor environment is solved, ventilation can be guaranteed by the blades of the inner layer, the rainwater can be further stopped, the bottom of the window is an inclined plane which has the high inner side and the low outer side, the rainwater blown in the outer layer in heavy rain can flow to an outdoor environment by using the bottom of the window, and the rainwater can be effectively prevented from being accumulated and flowing in the indoor environment.

Owner:ZHOUSHAN ELECTRIC POWER SUPPLY COMPANY OF STATE GRID ZHEJIANG ELECTRIC POWER +1

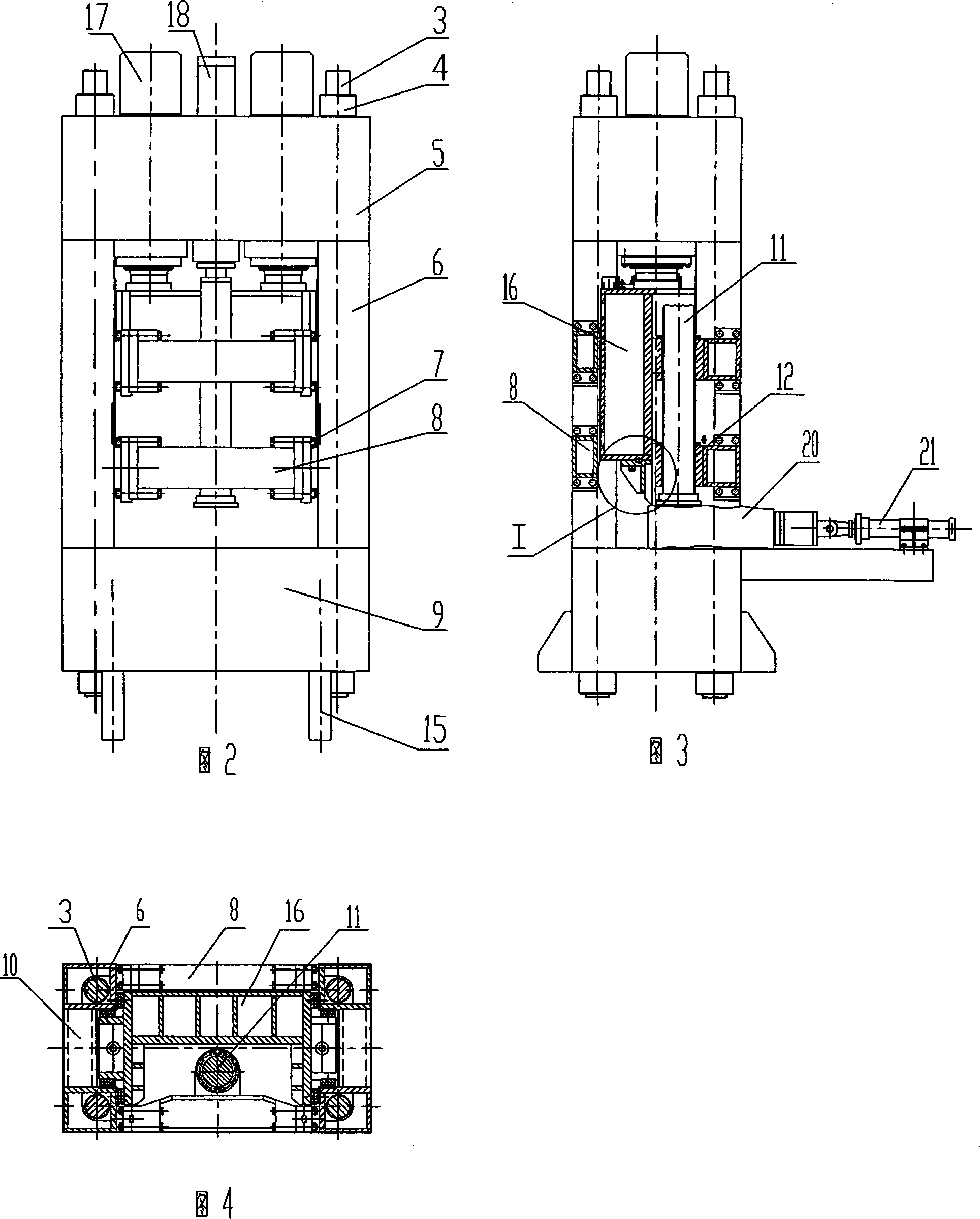

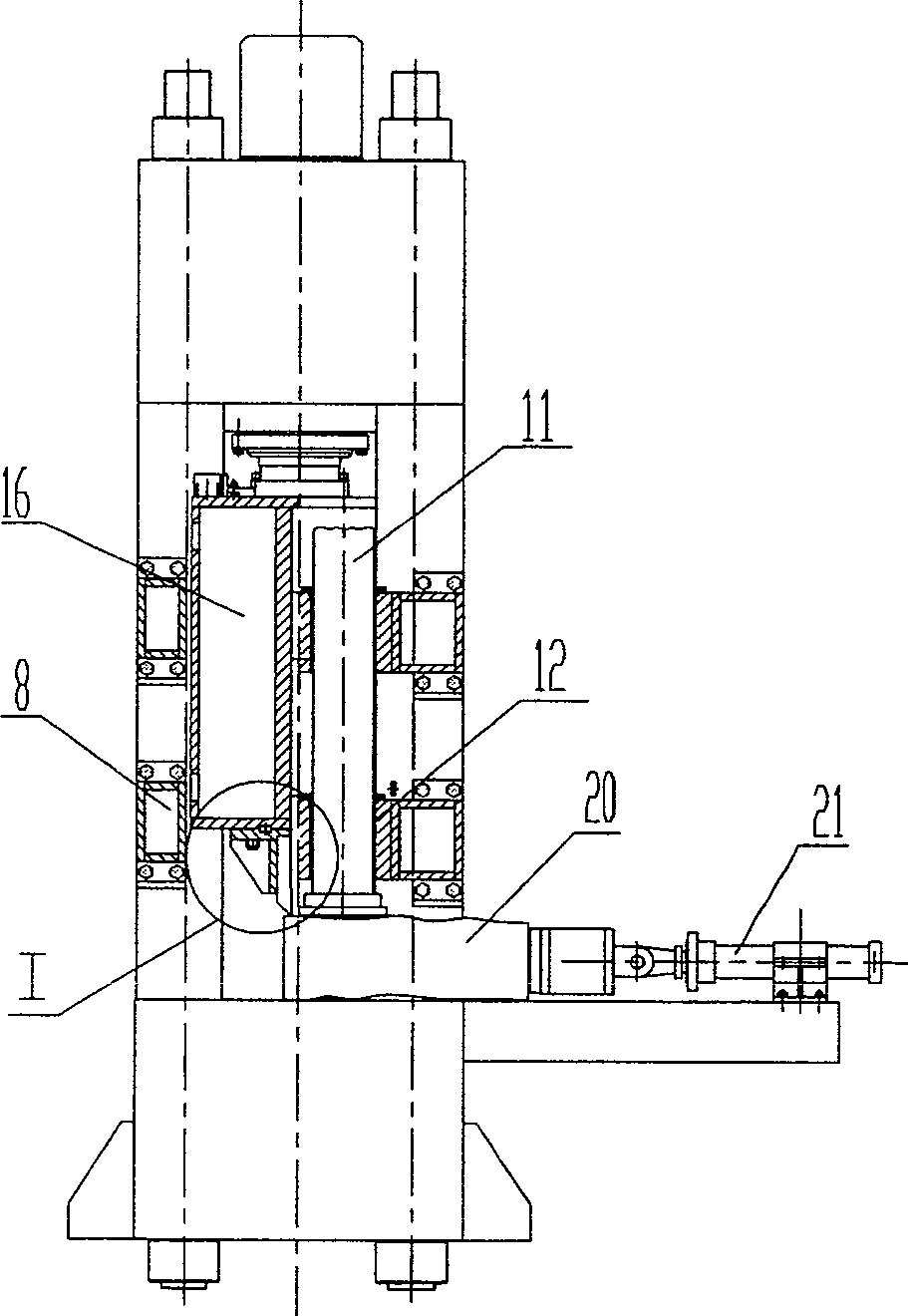

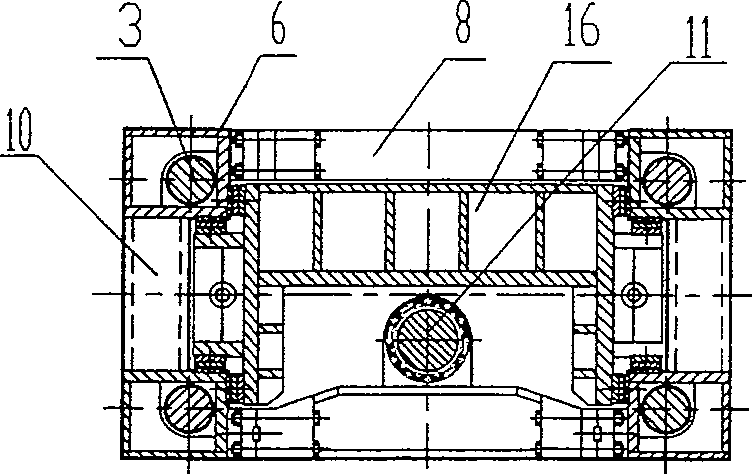

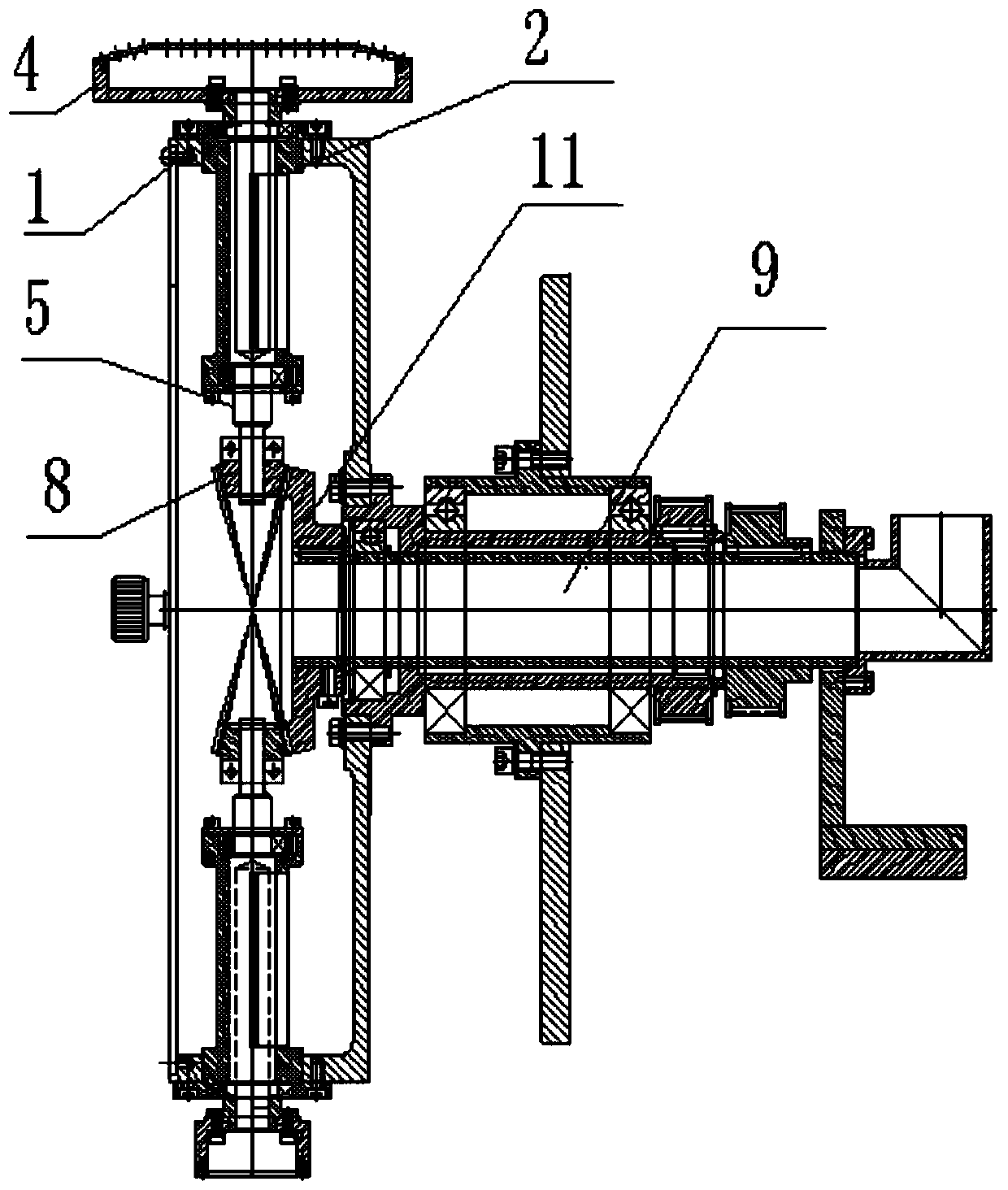

Frame type oleodynamic press for the crushing of titanium sponge knife

ActiveCN101176931AReduce distortionGuaranteed verticalityShearing machinesShearing machine accessoriesTitaniumBar pressing

The invention discloses a frame-type hydraulic press for sponge titanium jackknifing crush, belonging to the titanium alloy production facility. At present, the prior equipment applied for titanium lump crushing is the three-beam four-column jackknifing crush hydraulic press both at home and abroad, which has a plurality of drawbacks such as huge size, heavy weight, complex force condition of the components, bad rigidity of facility, high manufacturing cost and difficult maintenance. The invention is characterized in that: an upper beam, four frames and a lower beam of the hydraulic press form an enclosed force frame; four frames form an entirety; two cutting cylinders and one pressure cylinder are arranged on the upper beam; a plunger of the cutting cylinder is connected with a sliding block, the cutter connected on the sliding block, and the piston of the cylinder connected with the pressure rod, and a return cylinder and a push cylinder are arranged on the lower beam. The invention has the advantages of novel and simple structure, light weight, good rigidity, high precision, low manufacturing cost, long service life, easy maintenance and other advantages.

Owner:TAIYUAN HEAVY IND

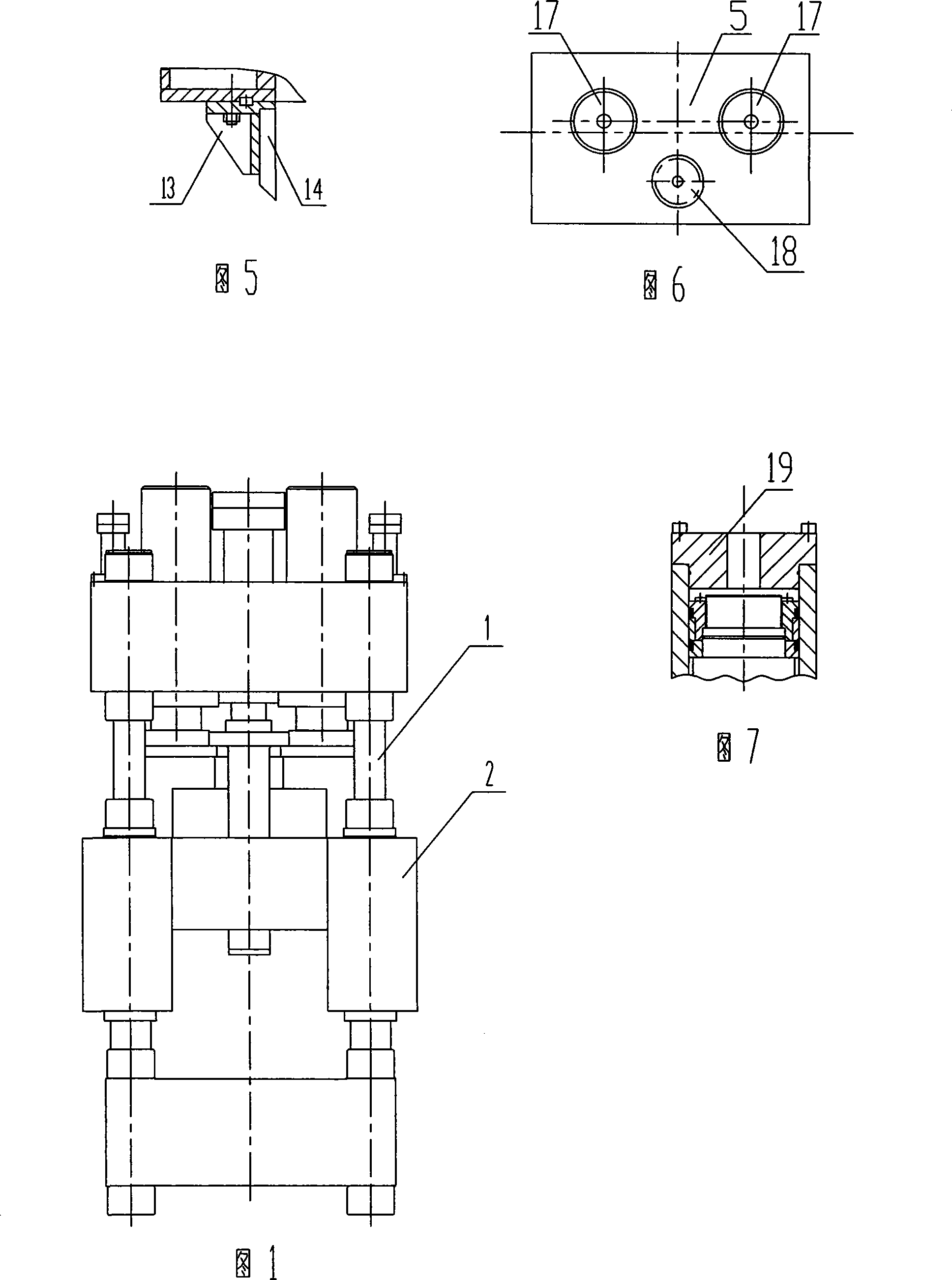

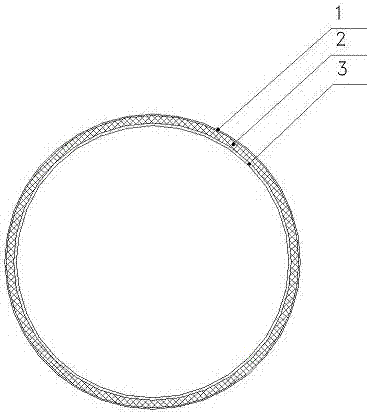

Insulation shell manufacturing process of glass steel integrated pump station and insulation shell

PendingCN106985419ASolve insulation problemsIncrease productivityTubular articlesInsulation layerComposite material

The invention discloses an insulation shell manufacturing process of a glass steel integrated pump station and an insulation shell. The process is characterized by comprising the following steps: (1) a pipe mold and a winding material are prepared; (2) a lining layer of a pump station shell is manufactured on the mold, and is heated for curing; (3) the heated and cured lining layer is wound with a structure layer for manufacturing the glass steel pump station shell; and the structure layer is cured; (4) after the structure layer in the step (3) is cured, an insulation layer and a glass steel baffle plate are prefabricated at the external of the structure layer; (5) after the insulation layer in the step (4) is manufactured, the insulation layer is checked and finished; (6) an outer shell is manufactured by secondary winding on the basis of the step (5); (7) after the outer shell is manufactured, the calendering and the demolding curing are performed; and (8) products are detected after the demolding curing; the qualified products are warehoused; and the unqualified products are repaired or scrapped.

Owner:LIANYUNGANG LIANXIN FRP

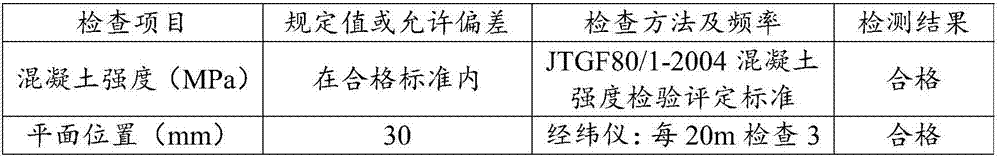

Construction method with aluminum alloy formworks as gravity type highway retaining wall formwork and retaining wall

InactiveCN107366303AMeet construction quality requirementsHigh strengthArtificial islandsUnderwater structuresForest resourceRetaining wall

The invention discloses a construction method with aluminum alloy formworks as a gravity type highway retaining wall formwork and a retaining wall and relates to the technical field of building construction. The technical problems that according to traditional formworks, the construction quality requirements of the gravity type retaining wall built at a mountain highway section adjacent to a cliff or a river cannot be meet, in addition, potential safety hazards exist, and forest resources are excessively consumed are relieved. According to the construction method with the aluminum alloy formworks as the gravity type highway retaining wall formwork, the aluminum alloy formworks are adopted to be assembled into the retaining wall formwork in a sectioned mode on a spacious site firstly, then the retaining wall formwork is hoisted to the designed position and fixed, and then concrete is poured; the construction quality requirements of the gravity type retaining wall built at the mountain highway section adjacent to the cliff or the river can be meet, besides, safety accidents can be reduced to the maximum limit, the construction speed can be also improved, and the constriction period is shortened; and meanwhile, the collapse phenomenon can be avoided, wood resources do not need to be consumed, and thus the energy-saving and environment-friendly beneficial effects are achieved. The retaining wall can take the effects of slope protection and edge protection for a long time.

Owner:江苏燕宁工程科技集团有限公司

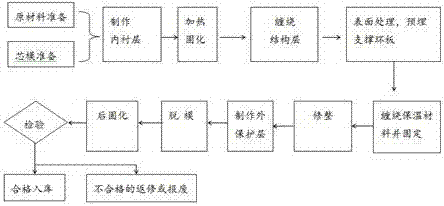

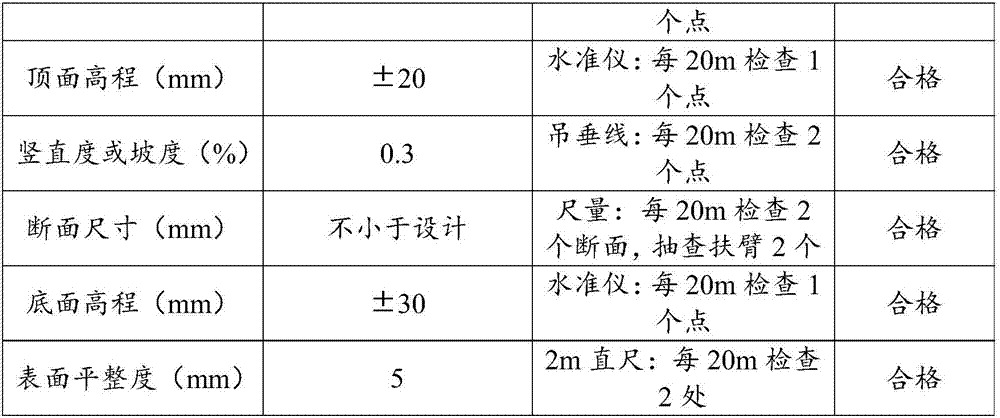

Die for valve core framework coated insulating silicone and using method thereof

The invention discloses a die for valve core framework coated insulating silicone and a using method thereof, belonging to the technical field of dies. The die for valve core framework coated insulating silicone, from top to bottom, sequentially comprises an injection-compression head, an upper die, a middle die and a lower die, wherein the injection-compression head is fixed on an upper hot plate of a forming machine, and the lower die is fixed on a lower hot plate of the forming machine; the die for valve core framework coated insulating silicone also comprises a sliding die core, the sliding die core is assembled on the lower die and located in a die cavity of the middle die, a valve core framework is located between the sliding die core and the inner wall of the die cavity of the middle die, and a position on the upper surface of the lower die and corresponding to the valve core framework is provided with granular bulges so as to ensure that the lower bottom surface of the valve core framework is not in contact with the upper surface of the lower die; the upper die compresses the sliding die core through a press block protruding downwards on the upper die, so that the sliding die core expands and locks the valve core framework. The die and the method disclosed by the invention can ensure that the thickness of a silicone coated layer on the surface of the valve core framework coated insulating silicone is flat and uniform, and a silicone coated surface has no waste rubber edge.

Owner:南京金三力橡塑有限公司

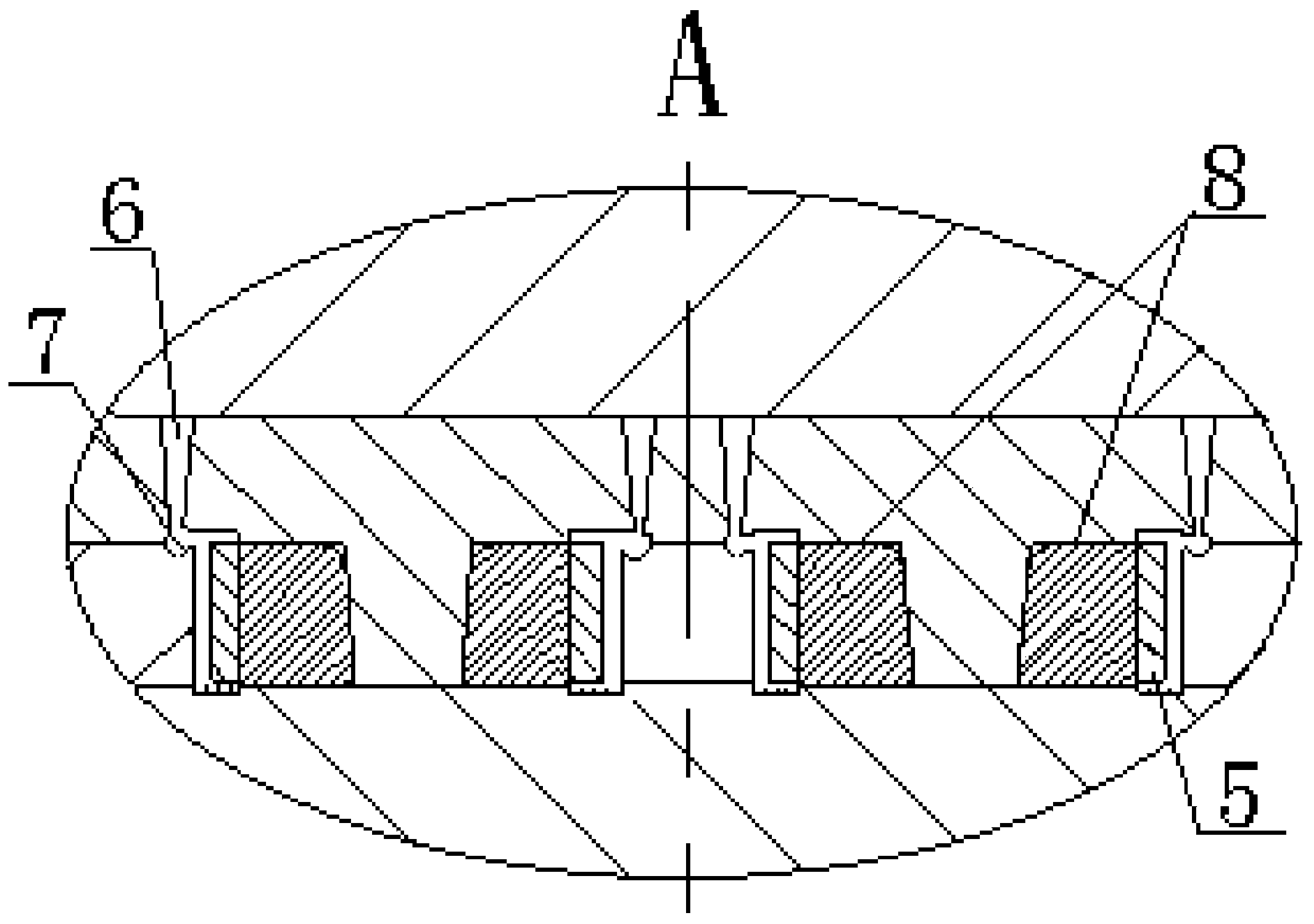

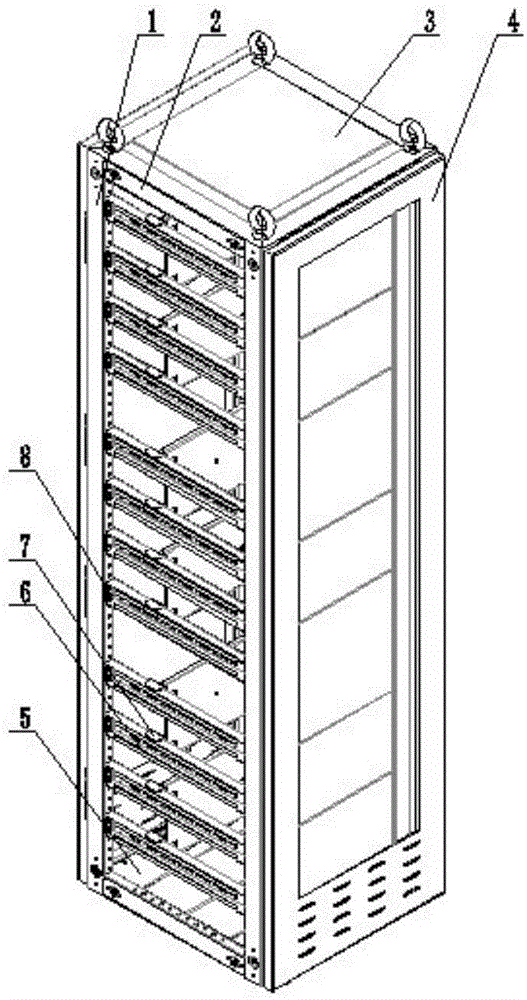

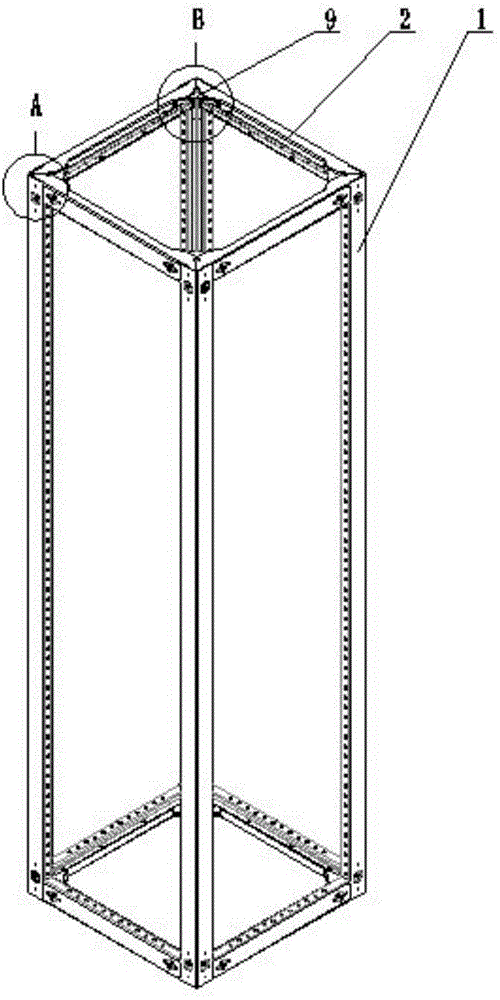

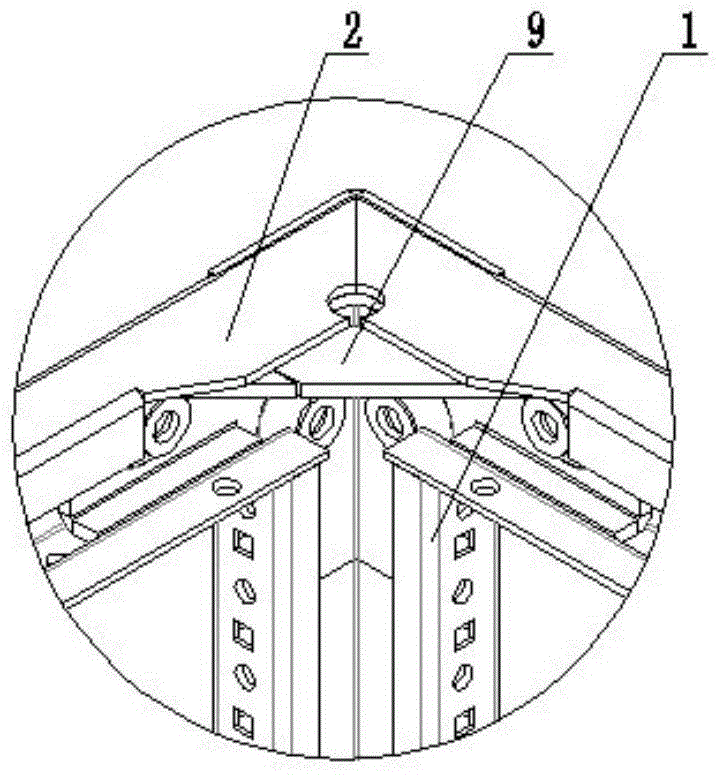

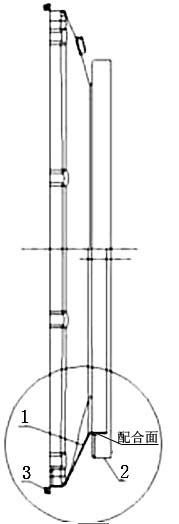

Novel 45-degree-wing-angle G sectional material switch cabinet

ActiveCN104466691AFlat and beautiful appearanceLow costSubstation/switching arrangement casingsStructural engineeringAlloy

The invention relates to a novel 45-degree-wing-angle G sectional material switch cabinet. A main body frame of a cabinet body is of a square frame-type structure composed of four stand columns and eight vertical main beams. The stand columns are made of reinforcement type open sectional materials, the main beams are made of 45-degree-wing-angle G sectional materials, and through fixing and positioning between metal plate tee joint parts and positioning holes and indenting counter bores of the stand columns as well as between the metal plate tee joint parts and positioning holes and indenting counter bores of the main beams, and positioning connecting between bayonets of the stand columns and the main beams, the stand columns and the main beams are fixed together. Side beams are fixedly and horizontally installed between the stand columns, and the two ends of each side beam are fixedly installed on the stand columns through protrusive connecting parts. An installing plate is vertically and fixedly installed between every two vertical adjacent side beams, and the two ends of each installing plate are fixedly installed on the corresponding side beam through connecting frames. The four corners of the switch cabinet are of wrapping-connecting assembly structures and are mainly formed by the stand column sectional materials, the main beam sectional materials and the metal plate tee joint parts in an inside and outside matching mode. The tee joint parts are concealed inside the wrapped corners composed of the main beams and the stand columns, the switch cabinet is attractive and flat in shape, the weight is reduced by over 60% compared with tee joint parts made of common aluminum alloy materials in a cast mode, and the cost can be lowered by over 90%.

Owner:TIANJIN RES INST OF ELECTRIC SCI +1

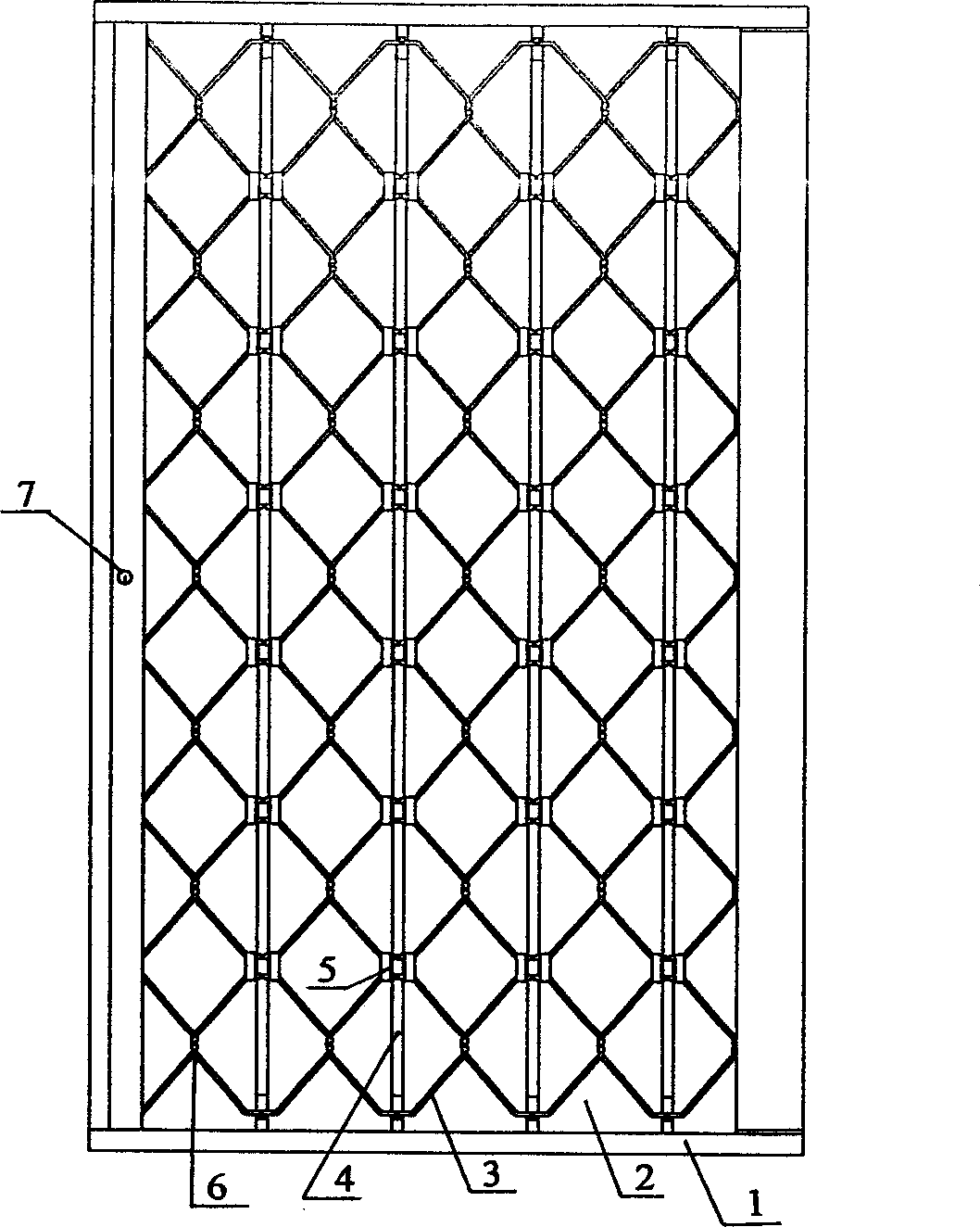

Folding safe window

InactiveCN1367302AImprove anti-theft performanceSimple structureShutters/ movable grillesSash windowEngineering

Owner:南京大策门窗有限公司

Surface tensile shearing antistatic bodkin single-side woolen and production method thereof

InactiveCN102978815ANot easy to decolorizeRich in colorWeft knittingDyeing processAfter treatmentPulp and paper industry

The invention discloses a surface tensile shearing antistatic bodkin single-side woolen and a production method thereof. The bodkin single-side woolen comprises surface silk and bottom silk, wherein the surface silk is formed by weaving 900D / 768F terylene, the 900D / 768F terylene is formed by twisting 30% common terylene and 70% cationic modified terylene in a texturing process, and the bottom silk is formed by weaving 150D / 48F terylene. As the common terylene is directly twisted with the cationic modified terylene in the texturing process, during the weaving process, cross strips caused by uneven network after the cationic modified terylene is combined with the common terylene do not exist; through the surface silk, radicals having excellent affinity with dispersive cationic dye are increased, so that the fabric is difficult to decolorize, and can be dyed under a normal temperature; the fabric is subjected to antistatic treatment, so that the problem that the terylene fabric easily generates static electricity can be effectively solved; and the anti-pilling performance of the fabric is increased through after treatment and sizing.

Owner:JIANGSU SHENGLI ENTERPRISE

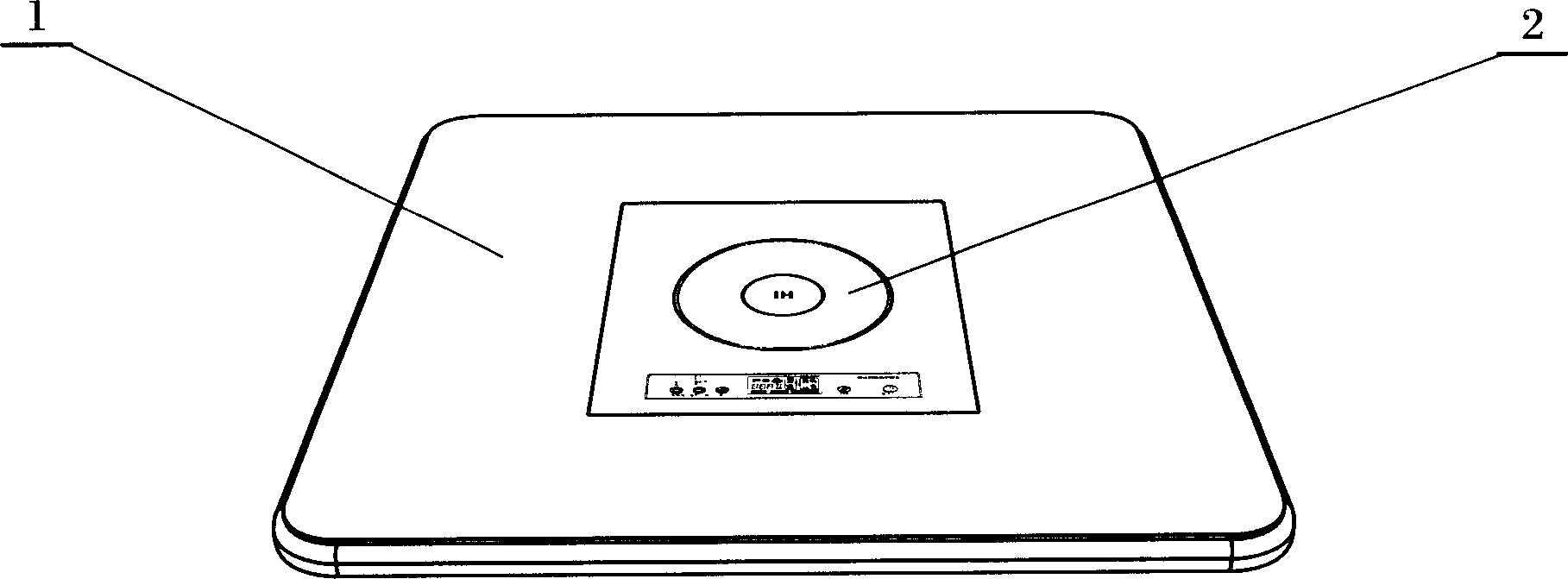

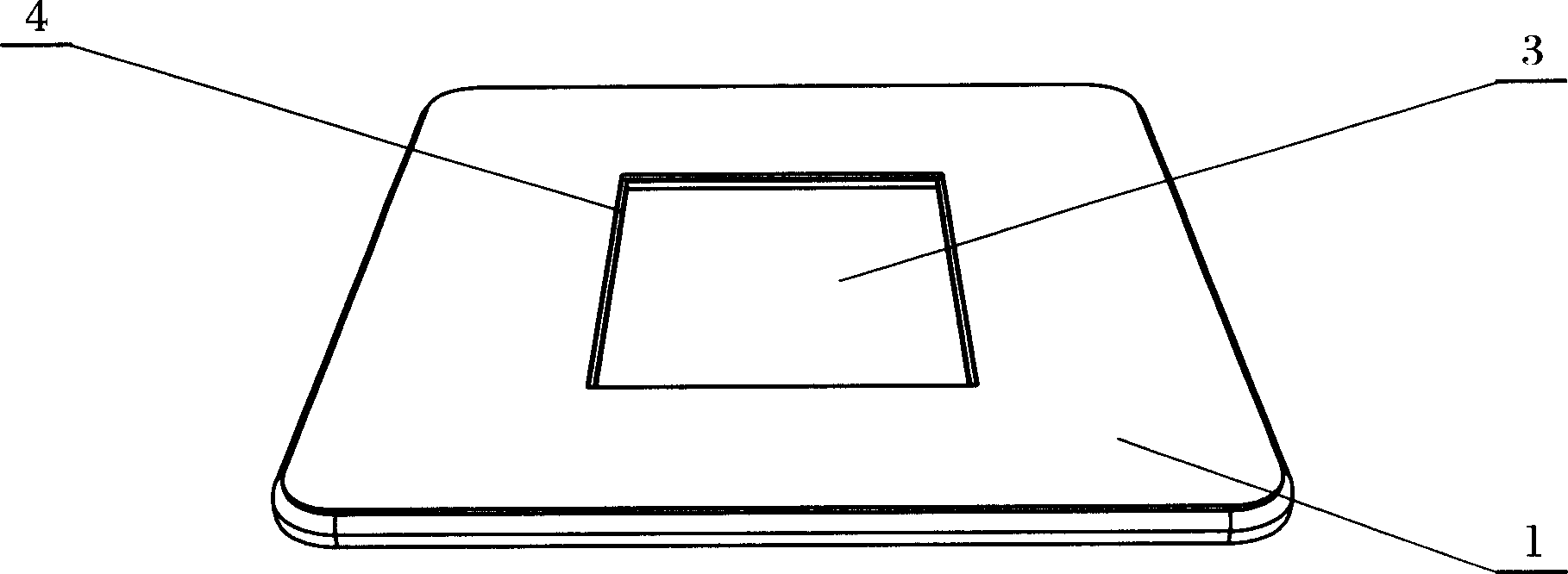

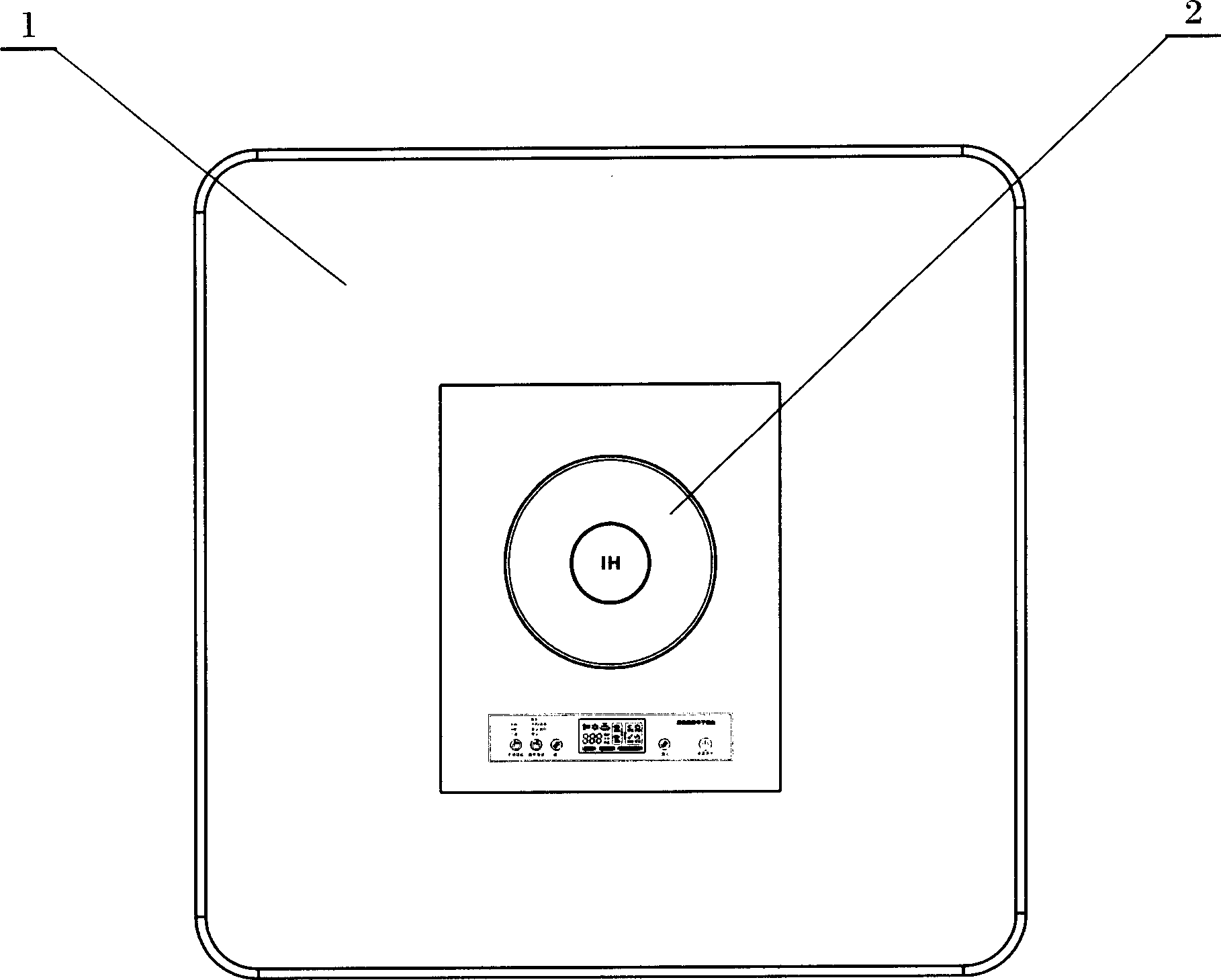

Electromagnetic oven panel structure

InactiveCN1811280ASimple structureFlat and beautiful appearanceDomestic stoves or rangesLighting and heating apparatusEngineeringToughened glass

The present invention is electromagnetic oven panel structure, and belongs to the field of table and multifunctional electric furnace technology. The panel has stepped opening for electromagnetic oven to be embedded in, and the electromagnetic oven has top plate of microcrystal glass or toughened glass and with touch switch. The present invention may have the panel made of different kinds of material and decorated with various patterns, and makes the electromagnetic oven easy to operate.

Owner:邓正刚

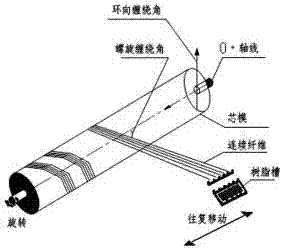

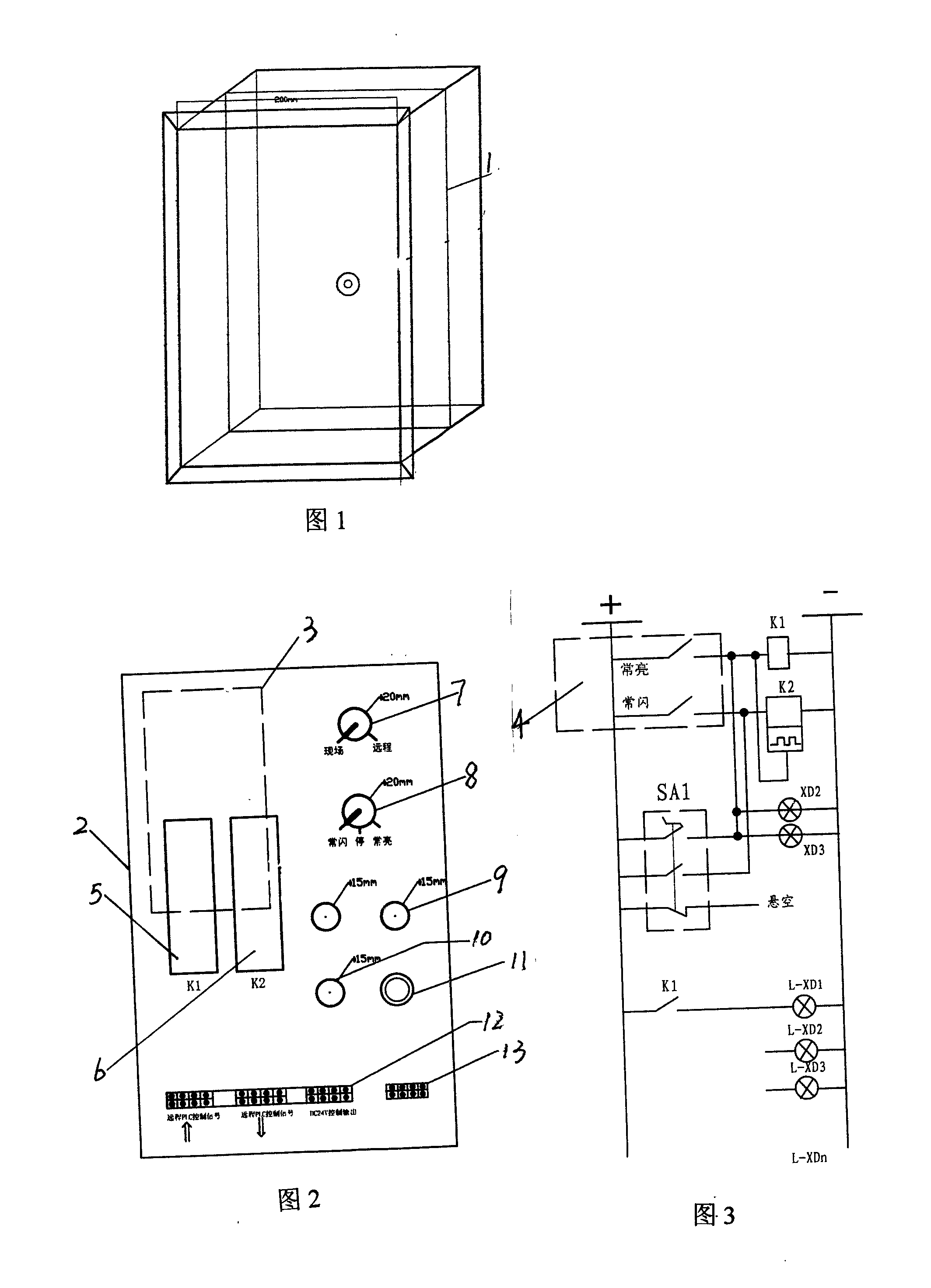

Profile mark controller device

InactiveCN101188889AOperational securityFunctionalElectric light circuit arrangementEnergy saving control techniquesControl signalTransfer switch

The invention provides a contour sign controller device, which relates to a control device of road traffic safety signs. The control device is composed of a control panel and a control box; the control panel 2 is positioned in the control box 1; the back of the control panel 2 is provided with a power supply 3 and a PLC 4; the front face of the control panel 2 is provided with an output relay 5, a relay 6 with pulse output time, a locale / long distance transfer switch 7, a locale control switch 8, a status indicator light 9, a power light 10, a power switch 11, a control signal wire connecting terminal 12 and a power wire connecting terminal 13; the control signal connecting end is respectively connected with the output relay 5 and the relay 6 with pulse output time, and communicated with the status indicator light 9; the locale control switch 8 and the locale / long distance transfer switch 7 are communicated with the output relay 5, and communicated with the status indicator light 9; a control end of the output relay 5 is connected with the relay 6 with pulse output time, and the output end of the output relay 5 is communicated with an active and illuminant contour sign. The invention has simple and convenient installation, as well as neat and beautiful appearance.

Owner:柏高权

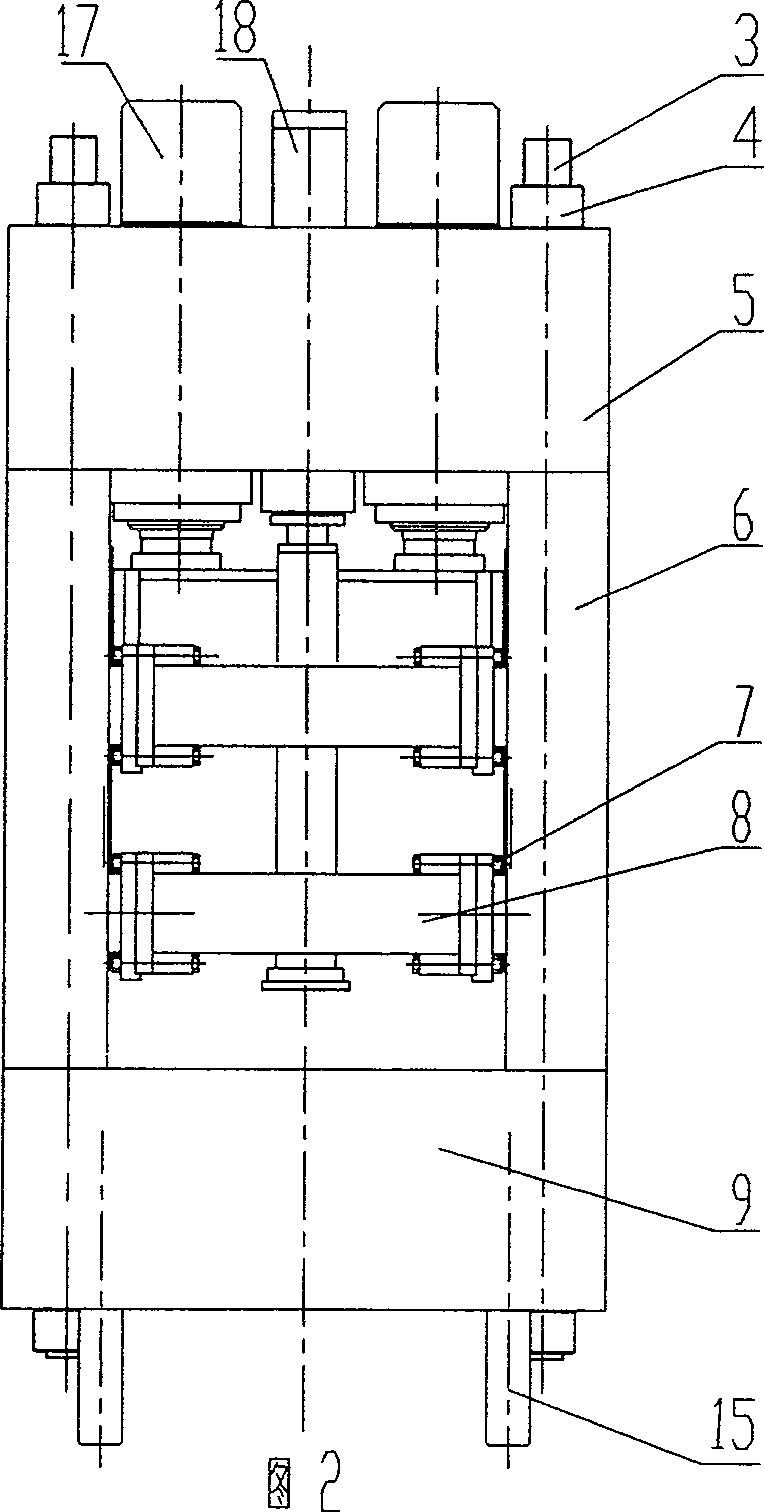

Frame type oil press for the titanium sponge knife for crushing

ActiveCN100491034CReduce distortionGuaranteed verticalityShearing machinesShearing machine accessoriesTitaniumBar pressing

The invention discloses a frame-type hydraulic press for sponge titanium jackknifing crush, belonging to the titanium alloy production facility. At present, the prior equipment applied for titanium lump crushing is the three-beam four-column jackknifing crush hydraulic press both at home and abroad, which has a plurality of drawbacks such as huge size, heavy weight, complex force condition of the components, bad rigidity of facility, high manufacturing cost and difficult maintenance. The invention is characterized in that: an upper beam, four frames and a lower beam of the hydraulic press form an enclosed force frame; four frames form an entirety; two cutting cylinders and one pressure cylinder are arranged on the upper beam; a plunger of the cutting cylinder is connected with a sliding block, the cutter connected on the sliding block, and the piston of the cylinder connected with the pressure rod, and a return cylinder and a push cylinder are arranged on the lower beam. The invention has the advantages of novel and simple structure, light weight, good rigidity, high precision, low manufacturing cost, long service life, easy maintenance and other advantages.

Owner:TAIYUAN HEAVY IND

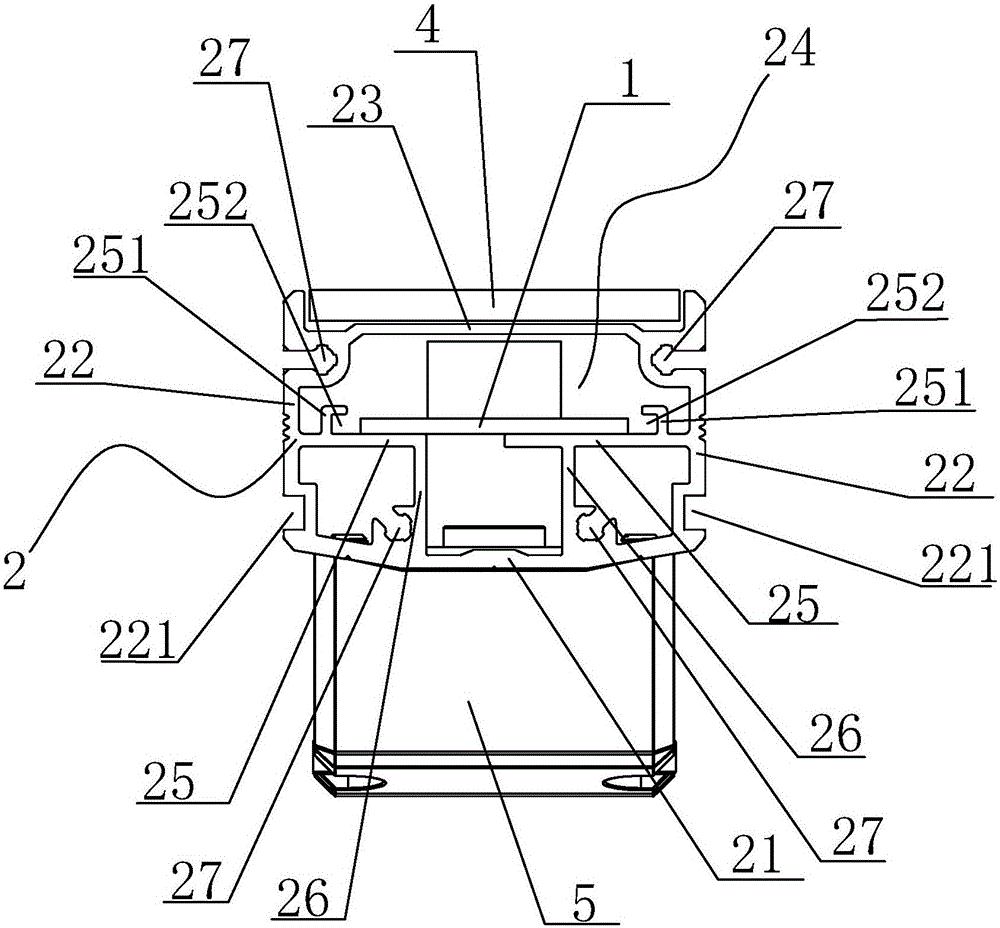

Waterproof and dustproof wall washer

InactiveCN106195790AFlat and beautiful appearanceWater seepage will not occurMechanical apparatusProtective devices for lightingEngineeringWater seepage

The invention discloses a waterproof and dustproof wall washer. The waterproof and dustproof wall washer comprises a light source plate, an integrally formed lamp outer shell, and two end covers used for covering the two ends of the lamp outer shell, wherein the lamp outer shell comprises a bottom plate, two side plates and a panel used for bonding a glass pressing plate; the bottom plate, the two side plates and the panel form a rectangular through cavity; the light source plate is placed inside the through cavity; shapes of the end covers and the two ends of the lamp outer shell are matched; and the edges of the end covers and the outer surface of the lamp outer shell are flush. According to the waterproof and dustproof wall washer, the appearance of the wall washer is smooth and beautiful, gaps capable of accumulating dust and seeping water are avoided, and the wall washer does not have the phenomenon of water seepage.

Owner:广东人和照明实业有限公司

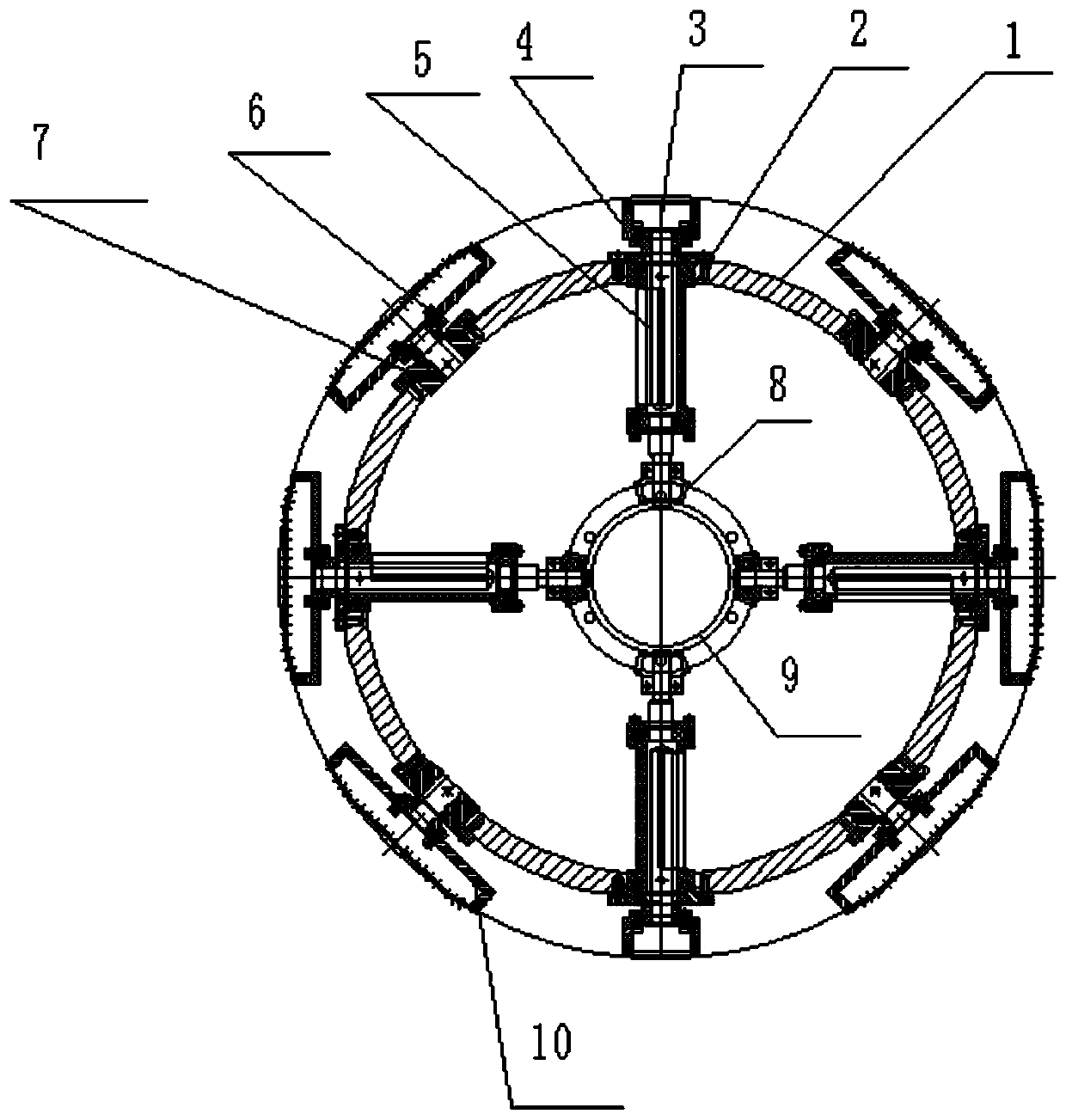

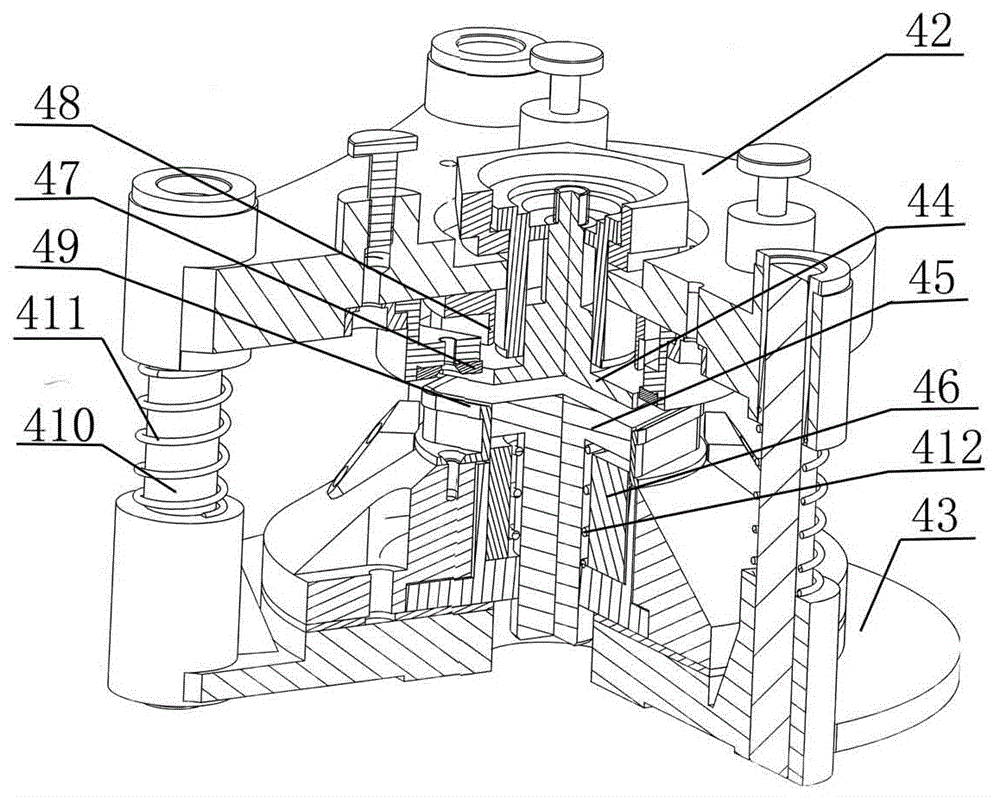

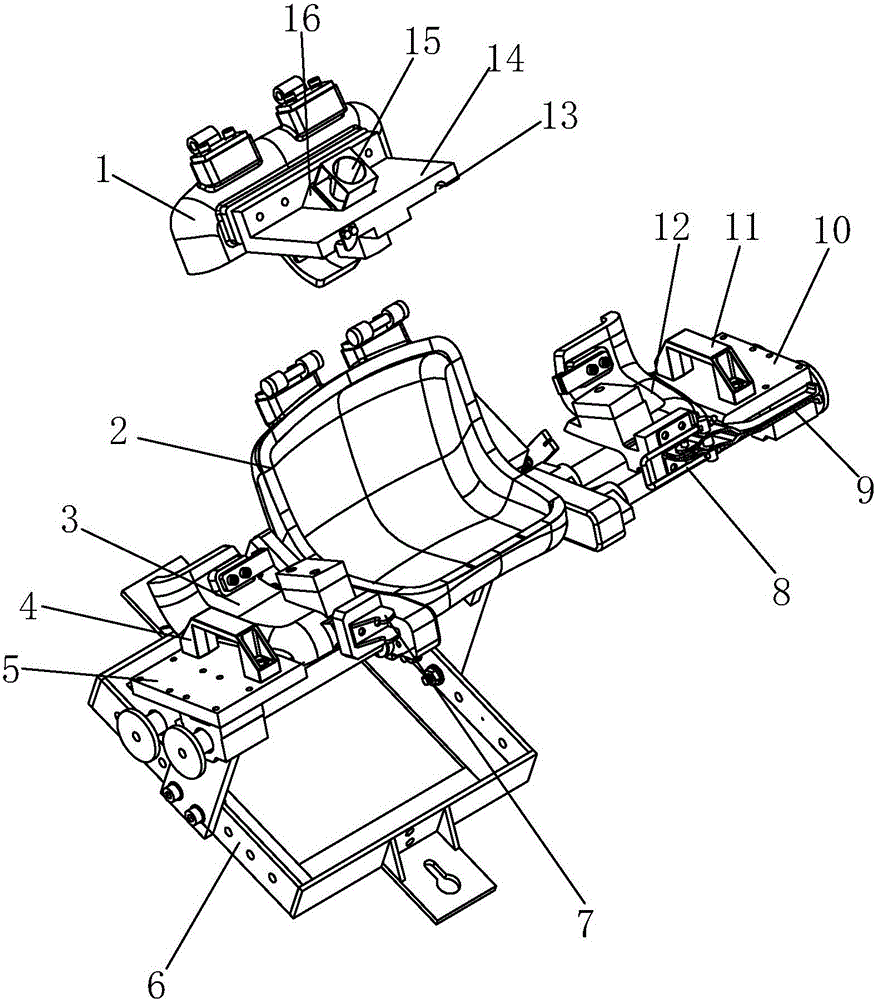

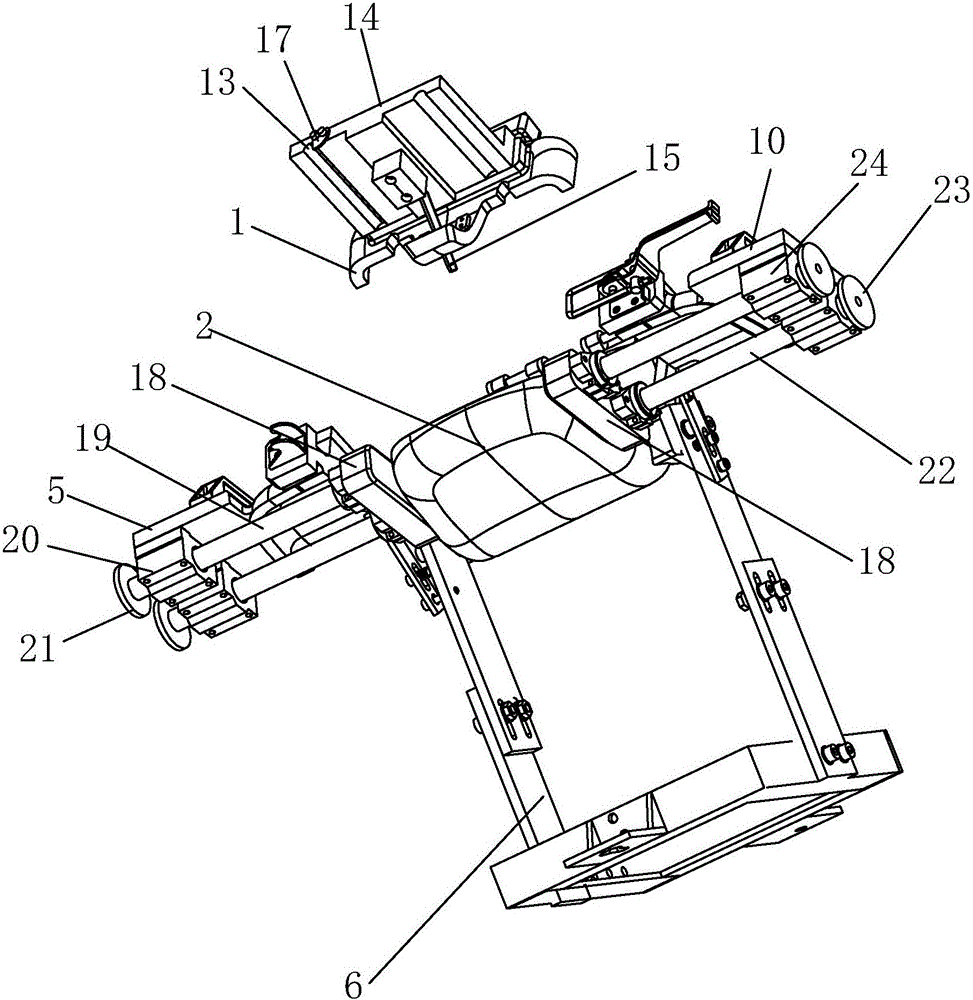

Packaging machine phase change mechanism

The invention relates to the field of packaging machines, in particular to a packaging machine phase change mechanism. The packaging machine phase change mechanism comprises a big fly wheel, four common variable balance devices and four sheet overturning variable balance devices. The four common variable balance devices and the four sheet overturning variable balance devices are all uniformly andalternately arranged along the big fly wheel. A big fly wheel rotary shaft is mounted at the center of the big fly wheel. The big fly wheel rotary shaft is driven to rotate by a motor to drive the bigfly wheel to rotate. The common variable balance devices are fixedly mounted on the big fly wheel. The sheet overturning variable balance devices are mounted on the big fly wheel and rotate along with the big fly wheel to automatically rotate to overturn sanitary pad packaging sheets. The packaging machine phase change mechanism provided by the invention is simple in structure, low in cost, highin efficiency and capable of automatically overturning the packaging sheets.

Owner:冠卓智能科技(浙江)有限责任公司

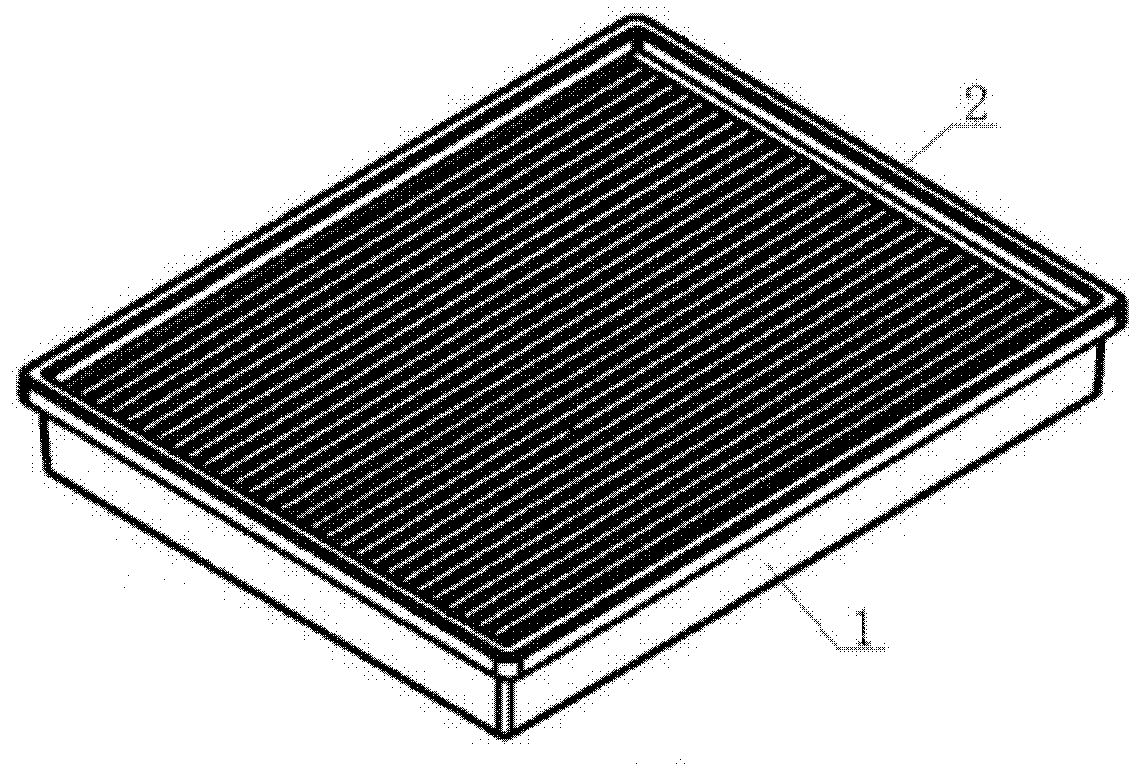

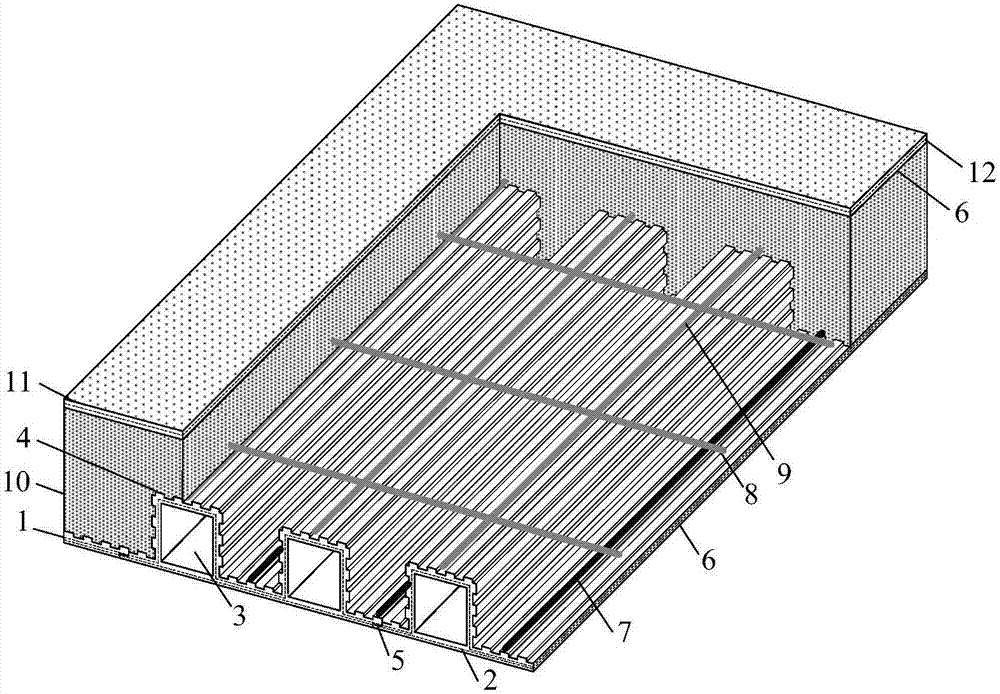

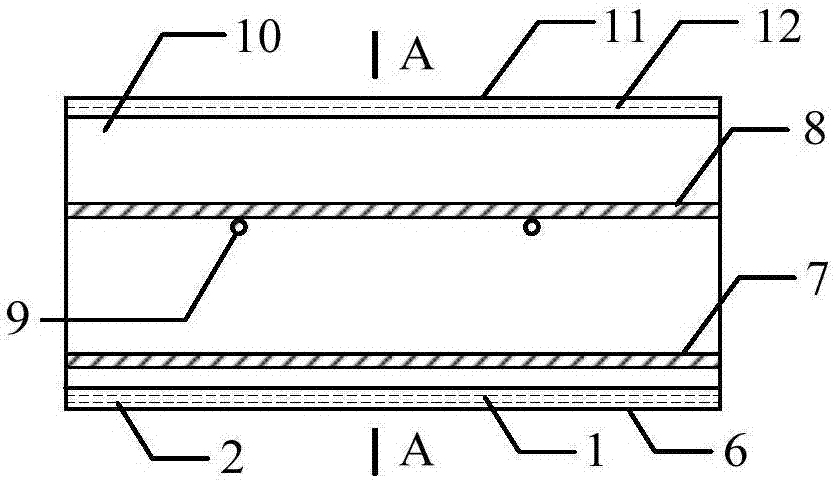

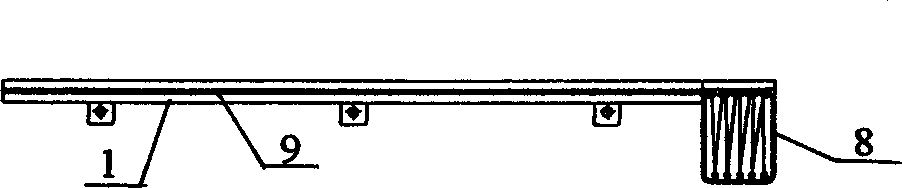

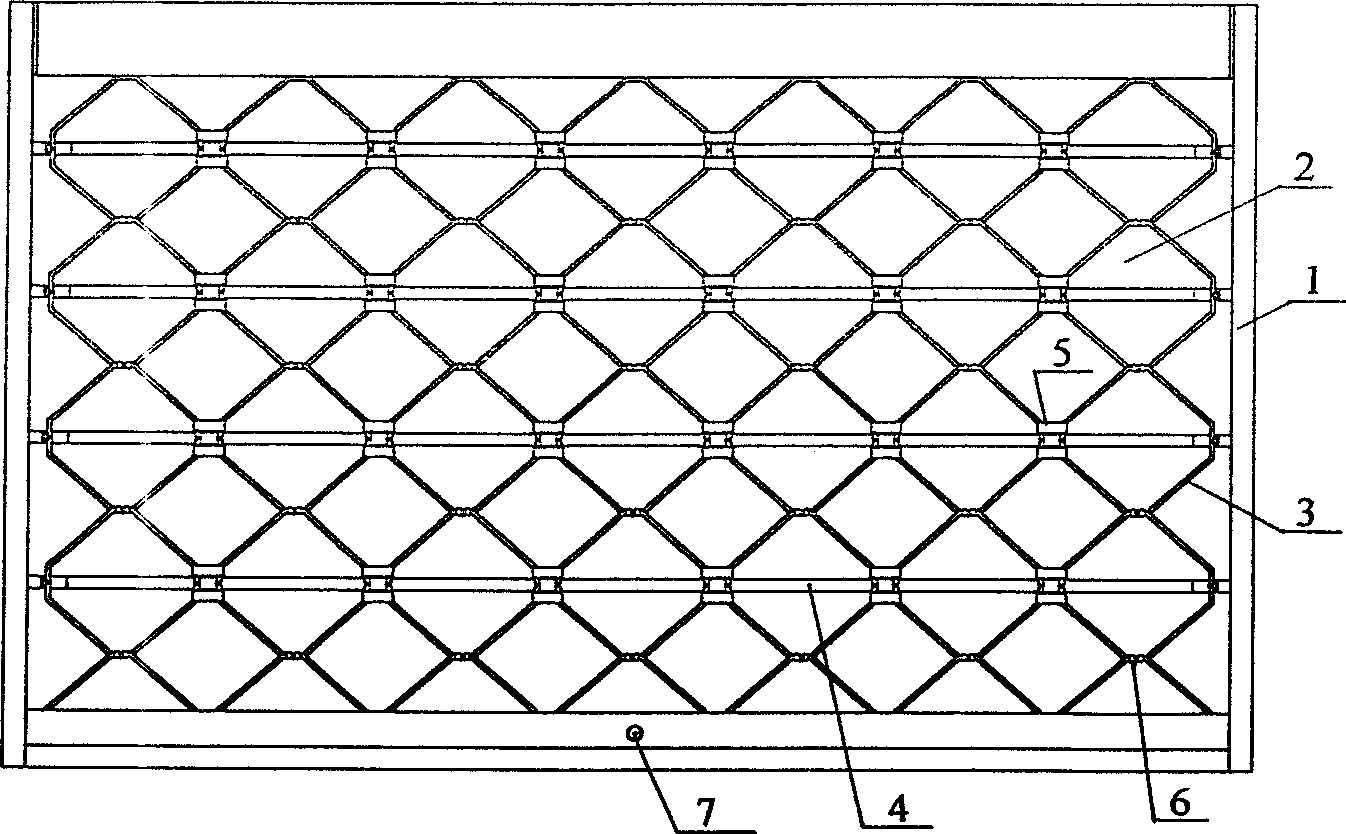

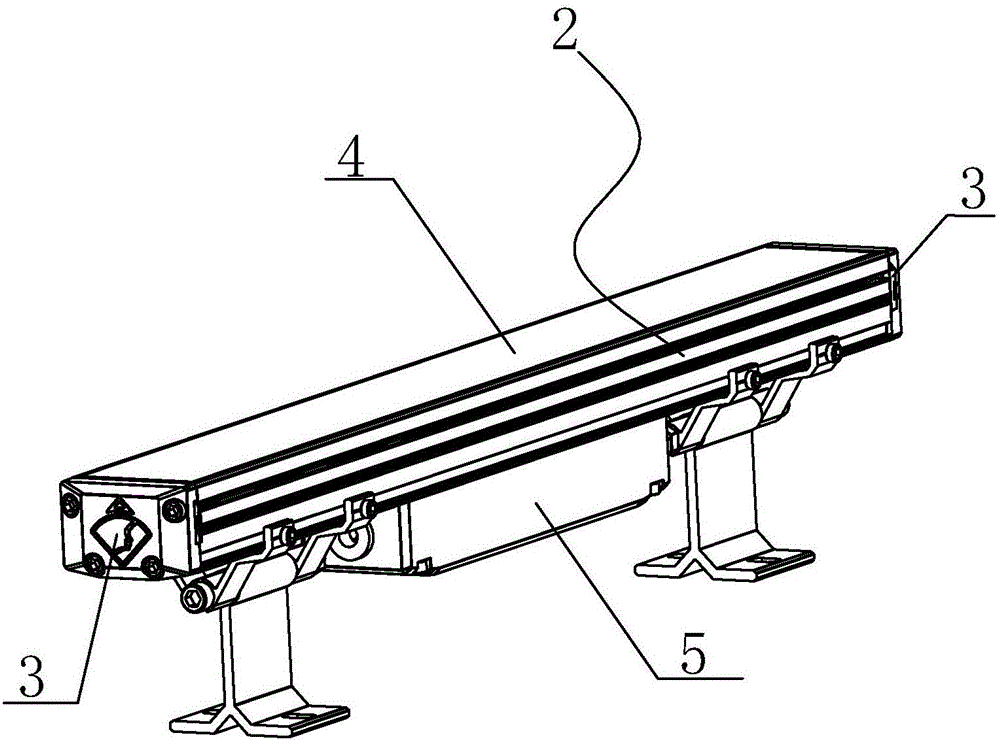

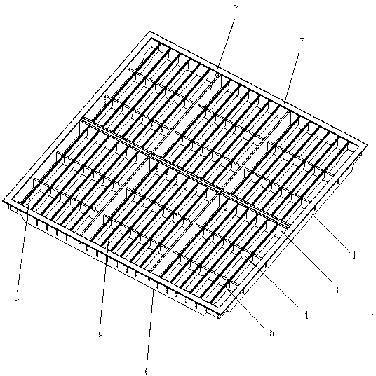

Overlap joint type structured airflow guide floor board

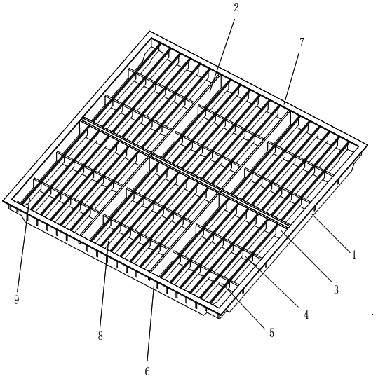

ActiveCN102704650AIncrease the applicability of matchingReduce manufacturing costLighting and heating apparatusSpace heating and ventilation detailsGratingEngineering

The invention discloses an overlap joint type structured airflow guide floor board, which comprises a first transverse beam, a second transverse beam, a first longitudinal beam, a second longitudinal beam, a third longitudinal beam, a fourth longitudinal beam, a panel, a first grating and a second grating, wherein the first transverse beam and the second transverse beam are parallel to each other; the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam are parallel to each other; the first transverse beam, the second transverse beam, the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam are vertically staggered; the panel is above the fourth longitudinal beam; and the first grating and the second grating are among the first transverse beam, the second transverse beam, the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam. According to the invention, by adopting the overlap joint type structure, the current problem that the opening rate and bearing contradict with each other is solved; and bearing also satisfies requirement of machine rooms in the event of increasing the opening rate.

Owner:SHANGHAI HUA YU ELECTRON ENG

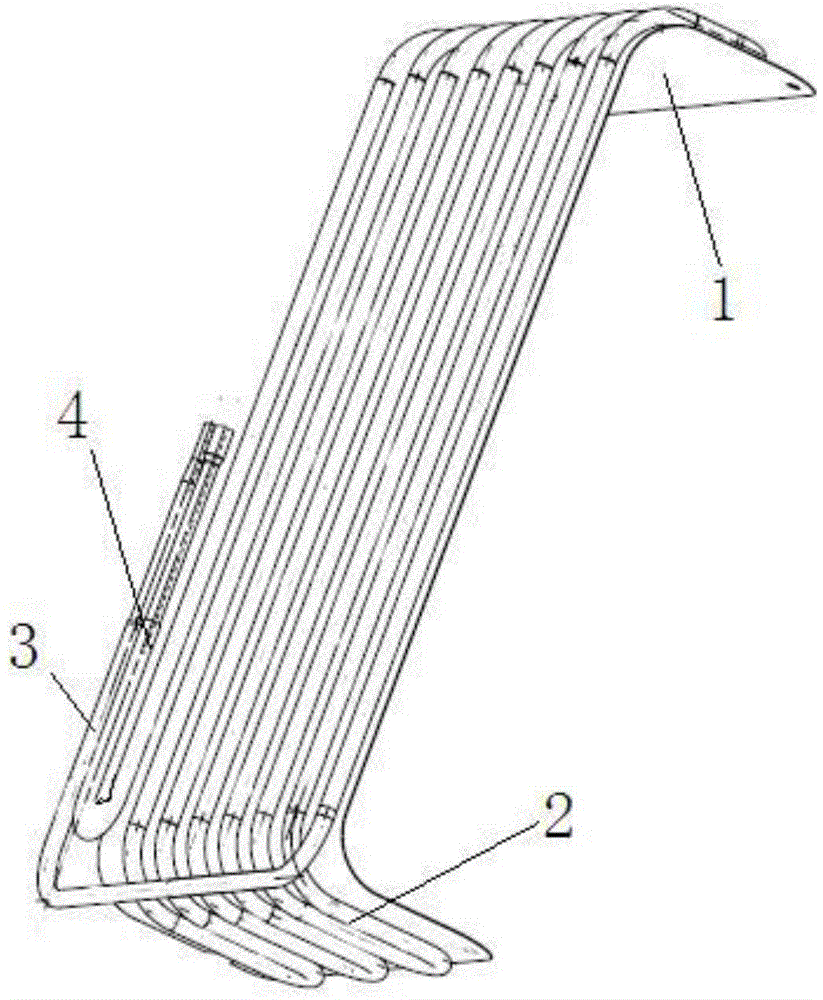

Manufacturing process of evaporator

The invention discloses a manufacturing process of an evaporator. The manufacturing process of the evaporator comprises the steps of 1, designing an aluminum plate structure, the diameter of aluminum pipes, and the distribution of the aluminum pipes on the aluminum plate according to the requirement on heat exchange capacity of a refrigerator and a display cabinet and the product mounting dimension; 2, bending the aluminum pipes into a snake-shaped aluminum pipe composed of a plurality of bent arc-shaped pipes and straight pipes; 3, pressing the snake-shaped aluminum pipe into a flat aluminum pipe; 4, coating soldering flux on the flat aluminum pipe, clamping and fixing the flat aluminum pipe and the aluminum plate through a clamp, and then soldering through a controllable atmosphere soldering furnace; 5, releasing the clamp after welding, and respectively welding and fixing an inlet pipe and an outlet pipe at the inlet end and the outlet end of the flat aluminum pipe; 6, spraying powder. According to the manufacturing process of the evaporator, the process is simplified, the production efficiency is increased, the product yield is high, the cost is low, and mass production can be carried out.

Owner:浙江康盛热交换器有限公司

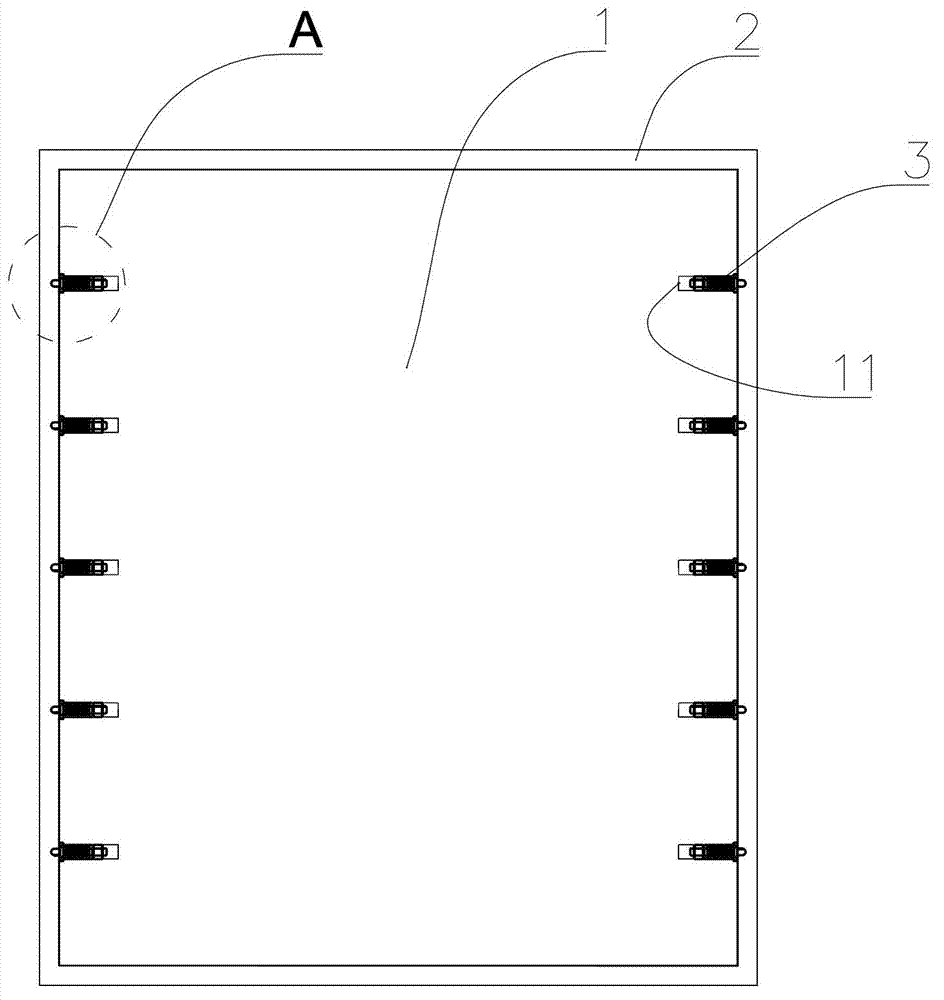

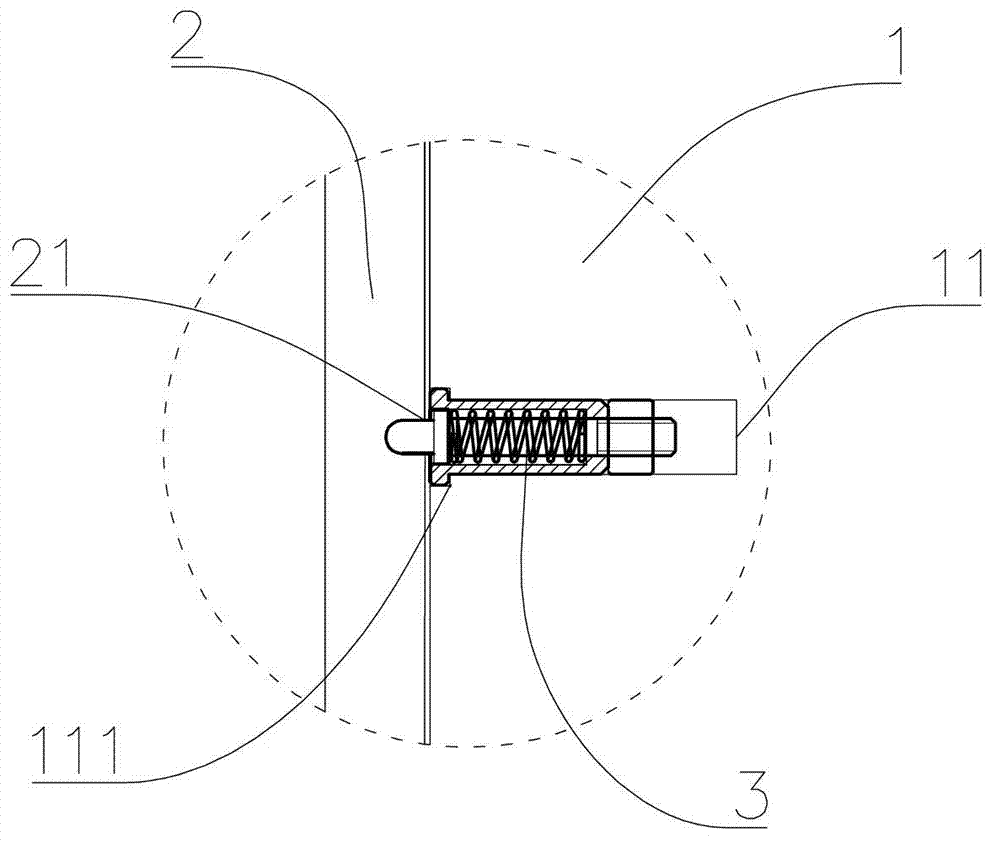

Furniture wall surface panel installation structure

InactiveCN102900734AFlat and beautiful appearanceEasy to installFurniture joiningOn boardEngineering

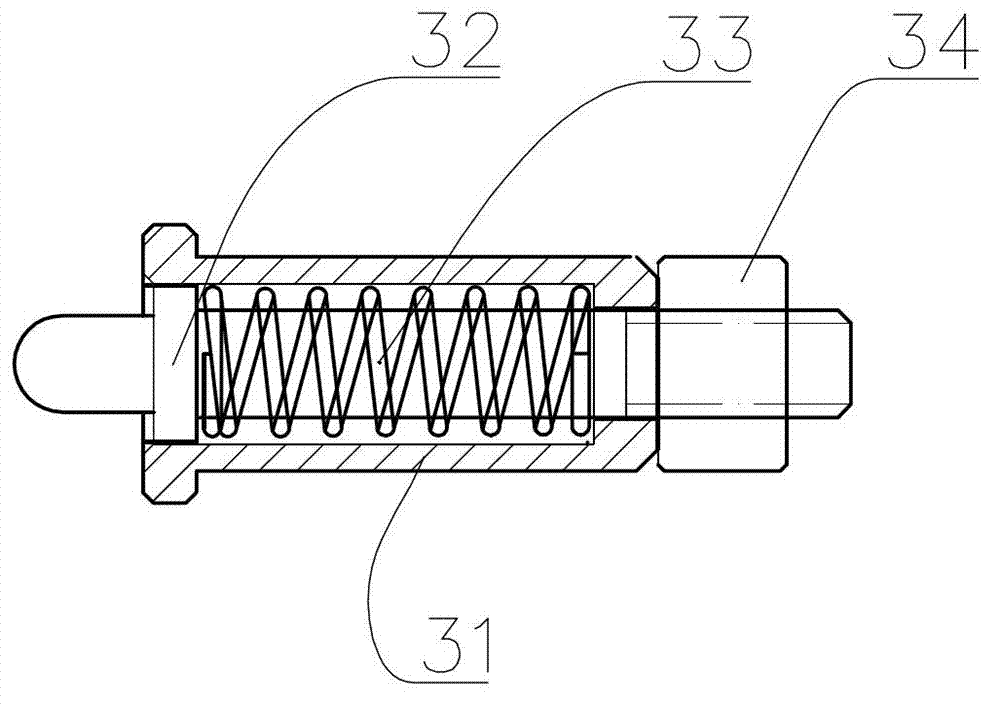

The invention discloses a furniture wall surface panel installation structure which comprises a metal frame and wooden boards matched in size with the wall surfaces formed by the frame. Connecting holes are arranged in the side walls of the outer circumferences of the wooden boards, and connecting pieces are arranged inside the connecting holes; clamping holes are arranged in the frame, at the positions corresponding to the connecting holes; the clamping holes are clamped with the outer ends of the connecting pieces in a matched way so as to fix the wooden boards on the frame; each connecting piece comprises a shell and a clamping shaft which is slidingly arranged inside the shell; and a spring is arranged between each clamping shaft and each shell to push the clamping shaft to stretch out towards the front end of the shell so as to be clamped with the corresponding clamping hole. According to the invention, the wooden boards are connected with the frame through connecting pieces, so when installing the wooden boards, an operator only needs to put the connecting pieces into the connecting holes at the side walls of the wooden boards, then aligns the connecting pieces with the corresponding clamping holes in the frame, and finally directly pushes the wooden boards to the clamping holes to be clamped through hands without using any tool. In such a way, the installation process can be accomplished without using any auxiliary tool, so the installation process is convenient and quick. The frame is connected with the wooden boards seamlessly, so the furniture is neat and beautiful in appearance.

Owner:ZHEJIANG RONGHUA FURNITURE

socket

ActiveCN106549247BFlat and beautiful appearanceNot easy to accumulateCouplings bases/casesEngineering

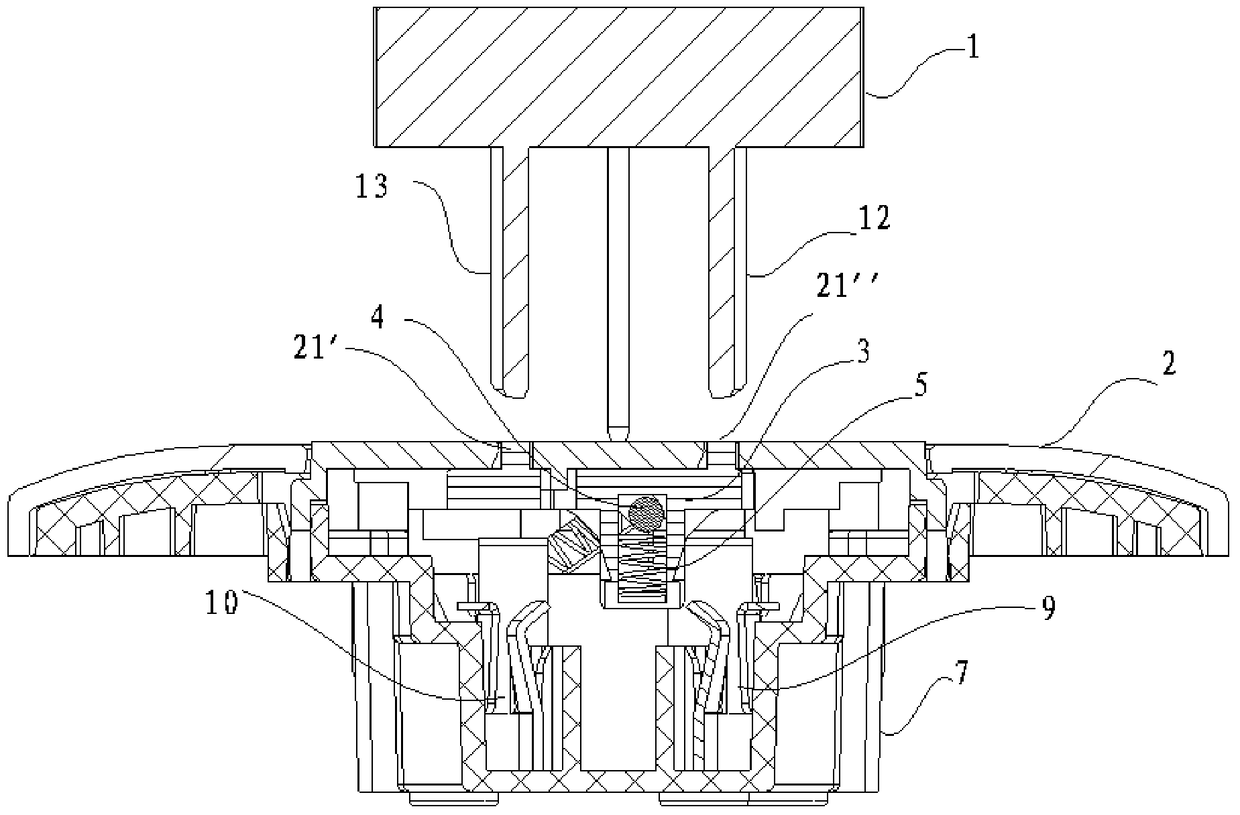

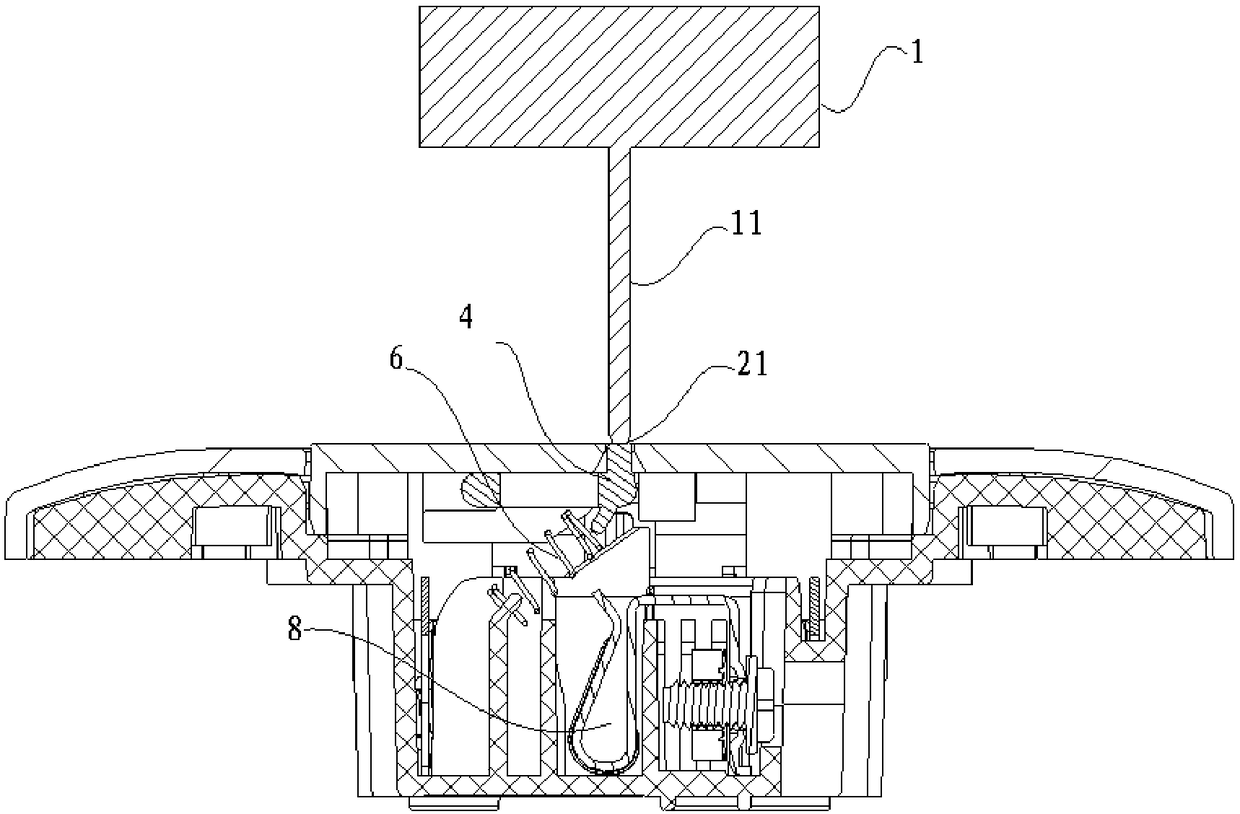

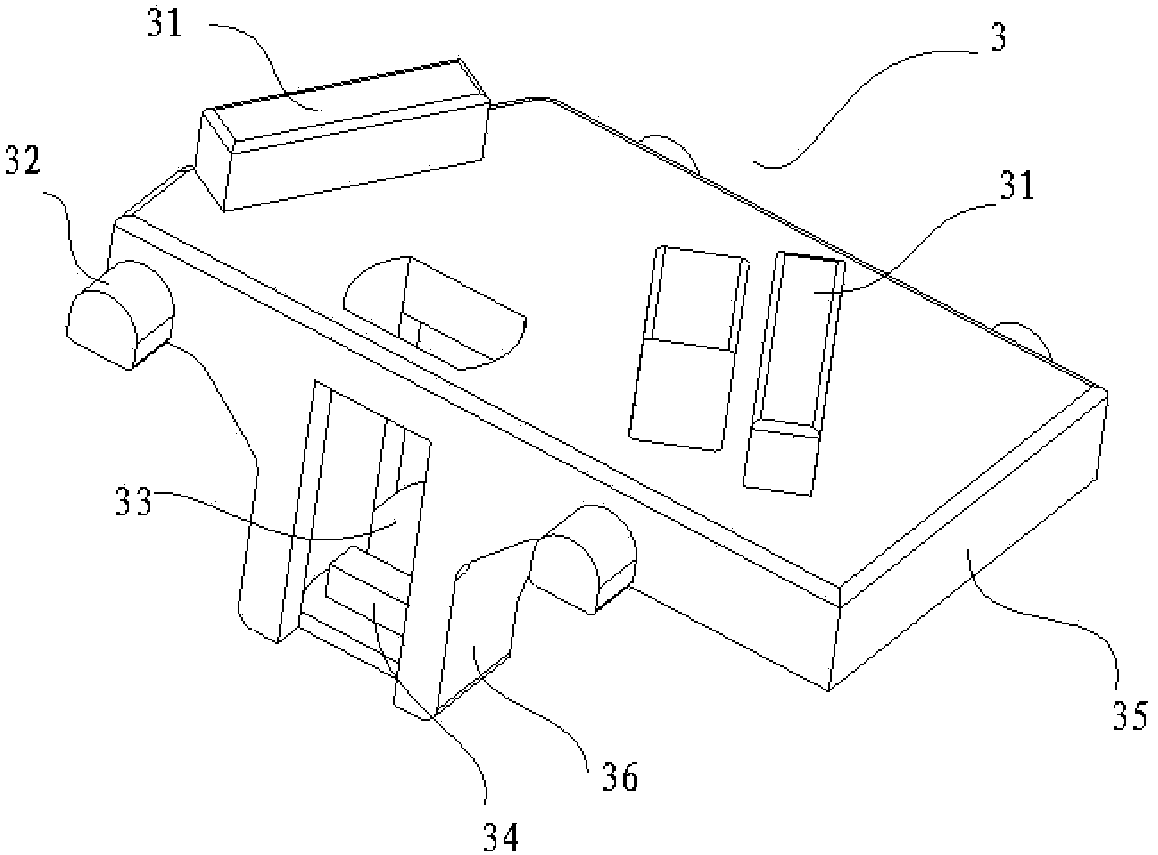

The embodiment of the invention relates to a socket. The socket comprises a socket body which is provided with three insertion holes (21, 21',21'') for respectively accommodating three pins (11, 12, 13) of a plug (1) therein; the socket body is internally provided with an E-pole protection door (4) for the E-pole insertion hole (21) among the insertion holes and an LN-pole protection door (3) for the L-pole insertion hole (21') and the N insertion hole (21'') among the insertion holes, the E-pole protection door (4) and the LN-pole protection door (3) are configured to enclose the corresponding insertion holes when no corresponding pins are inserted into the corresponding insertion holes and open the corresponding pins when the corresponding pins are to be inserted into the corresponding insertion holes, the E-pole protection door (4) and the LN-pole protection door (3) are assembled together, and the E-pole protection door (4) drives the LN-pole protection door (3) to move together. The socket has a flat and beautiful appearance and is suitable for a three-hole flat plug.

Owner:SCHNEIDER ELECTRIC (AUSTRALIA) PTY LTD

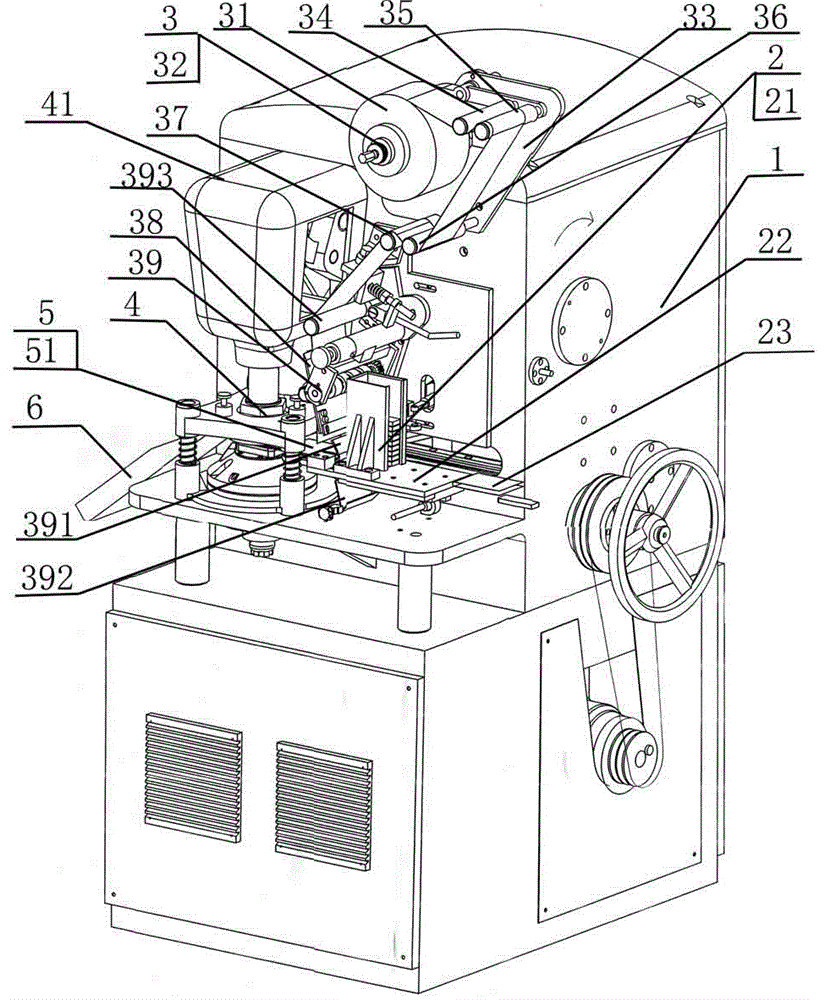

Polygon chocolate single-punch packing machine

InactiveCN106516275ACompact designEasy to operateWrapper folding/bending apparatusPunchingEngineering

The invention relates to the field of food packing machines, in particular to a polygon chocolate single-punch packing machine. The polygon chocolate single-punch packing machine comprises a box body, a sugar pushing mechanism, an aluminum-foil paper folding mechanism, a punching embossing mechanism, a paper cutting device and a finished product discharging outlet. The punching embossing mechanism comprises a transmission mechanism, an upper pressing cover, a base, an upper embossing punching head, a lower embossing punching head, a lower embossing punching head limiting block, an upper paper cutter, an upper sleeve shell mold, a lower sleeve shell mold, a guide column, a guide column spring and a lower embossing punching head spring. The polygon chocolate single-punch packing machine has the advantages that the design is compact, and operation is convenient; polygon sheet chocolates can be automatically packed; blocking is avoided during operation; product packing is in place; and the products are beautiful and smooth in appearance and meet the market requirements.

Owner:如皋市嘉美食品有限公司

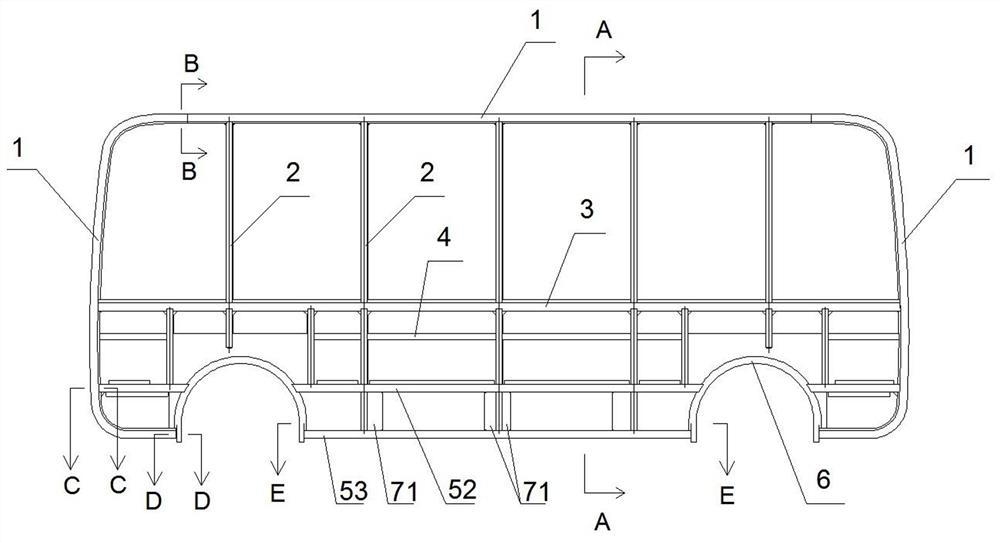

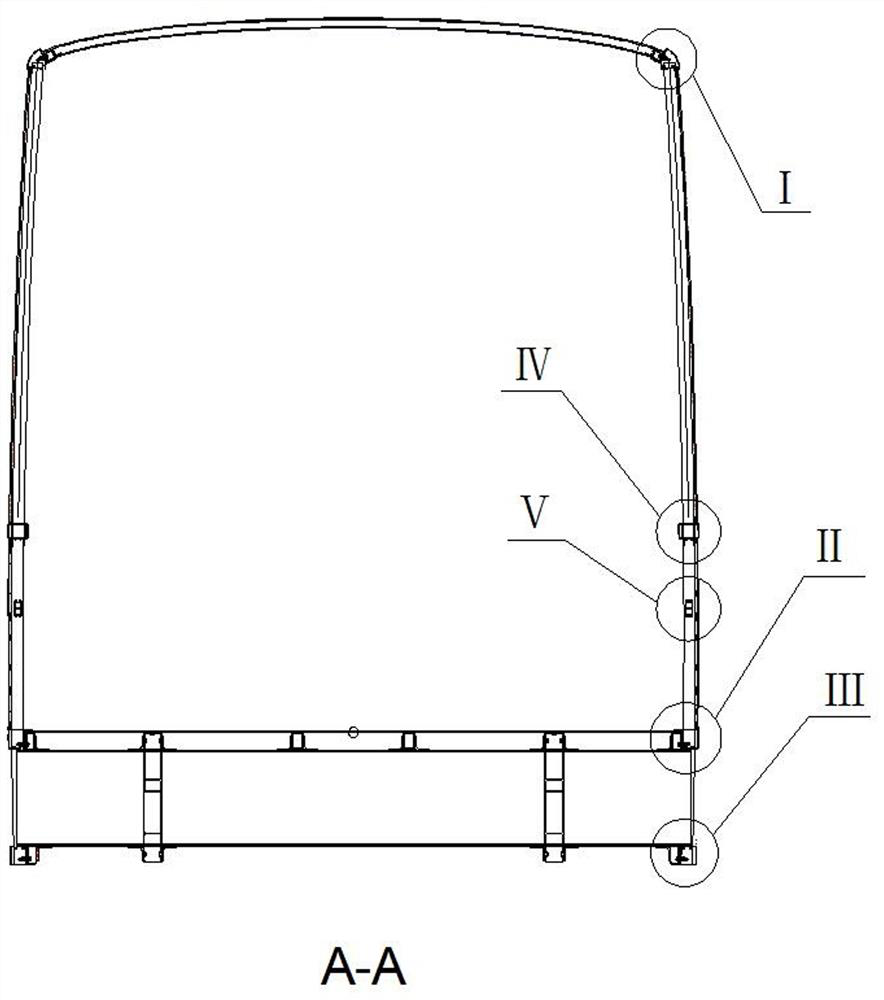

Mortise and tenon type side wall structure of all-aluminum alloy vehicle

PendingCN113212564AIncrease stiffnessSimple assembly and manufacturing processElectric propulsion mountingSuperstructure subunitsVehicle frameMortise and tenon

The invention discloses a full-aluminum alloy vehicle mortise and tenon type side wall structure. The structure is characterized in that a side wall comprises an outer contour formed by a side wall edge beam, a lower bottom beam and a wheel eyebrow frame, a plurality of cross beams and a plurality of stand columns are arranged in the outer contour, glass is installed in the upper area of a waist line cross beam, and an aluminum alloy panel is installed in the area between the waist line cross beam and the floor bottom beam; and a connecting structure between the floor bottom beam and the frame is designed in an area between the floor bottom beam and the lower bottom beam. Through the unique section design of the section bars, various mortise and tenon joints between the section bars are achieved, the section bars are further assembled and connected with the panel, the all-aluminum-alloy vehicle side wall structure module is formed, and the all-aluminum-alloy vehicle side wall structure module has the advantages of being light in weight, good in rigidity, easy to manufacture, low in manufacturing cost and the like; and the surface area between the floor bottom beam and the lower bottom beam is in assembly connection with the frame module, so assembly rigidity of the side wall is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

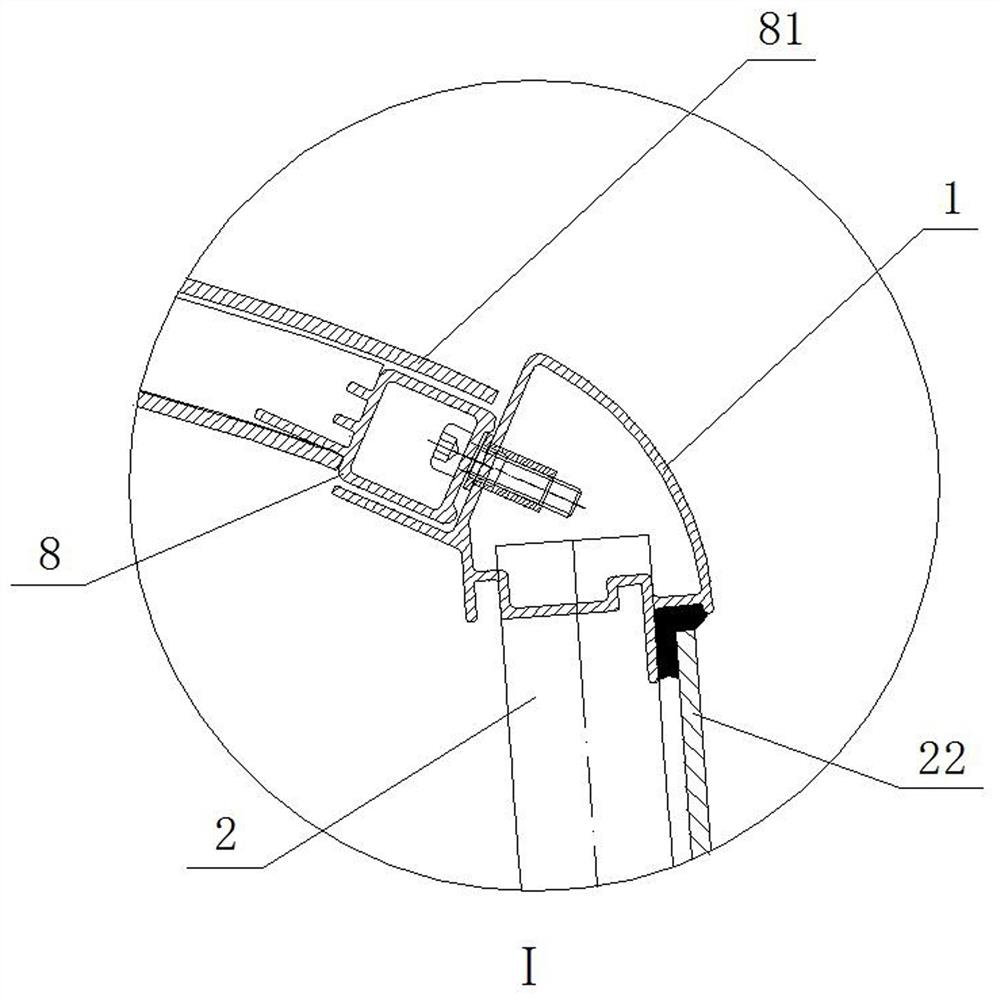

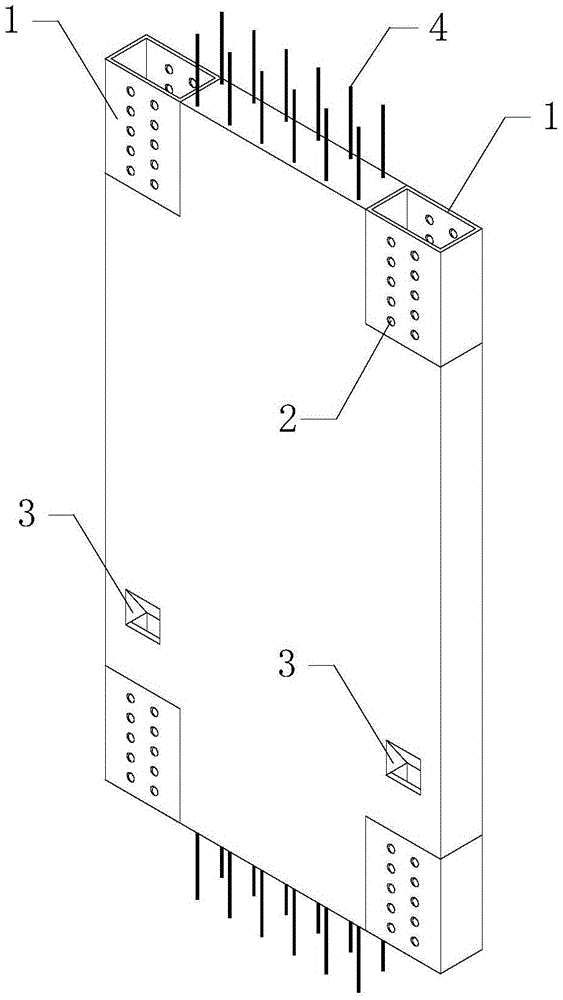

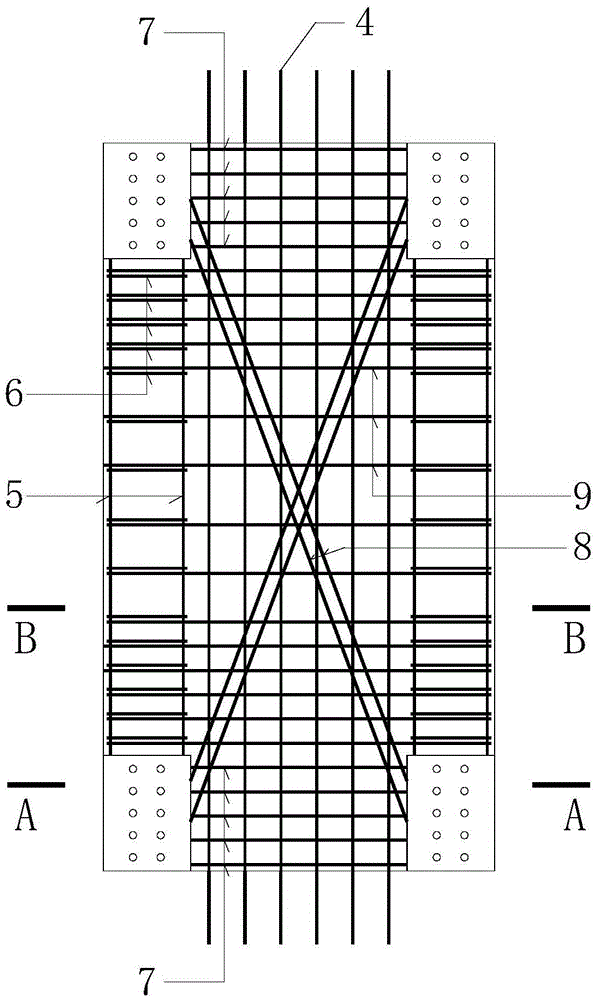

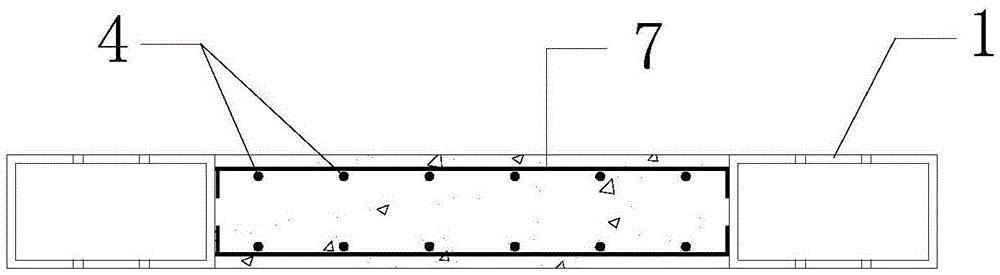

A prefabricated shear wall and wall-beam connection structure with edge restraint components

ActiveCN103883034BImprove seismic energy dissipation characteristicsFirmly connectedWallsHigh energyClassical mechanics

The invention discloses an assembled shear wall and a wall-beam connection structure with edge constraining components. The structure includes a shear wall and a beam prefabricated by concrete. The four corners of the shear wall are preset with rectangular steel pipes, the upper and lower sides are preset with steel bars, and the bottom of the shear wall is provided with a feed inlet. Both sides of the shear wall are provided with concealed columns, and the longitudinal bars of the concealed columns are welded on the inner side of the rectangular steel pipe; the described shear wall is provided with cross reinforcement, and the two ends of the cross reinforcement are welded on the outside of the rectangular steel pipe. A steel plate and a grouting sleeve are pre-embedded on the beam. The upper and lower walls are initially connected by connecting steel plates, tension bolts, longitudinal reinforcement protruding from the wall, and embedded sleeves in beams, etc., and then the final connection is realized by post-cast concrete. The invention has the advantages of high energy consumption during earthquakes, convenient hoisting and docking, fast installation and the like. It can be widely used in the assembled monolithic frame-shear wall structure, and has broad engineering application prospects.

Owner:SOUTHEAST UNIV

Welding structure for annular-wave metal corrugated pipe, and production method thereof

ActiveCN109654309ABeautiful appearanceReduce stress levelsAdjustable jointsNon-disconnectible pipe-jointsEngineeringSeam welding

The invention relates to a welding structure for connecting an annular-wave metal corrugated pipe, and a production method. The welding structure is characterized in that a circumferential welding seam is formed in the sidewall of corrugation, and a simple and reliable lap seam welding structure is adopted. The production method comprises the following steps: superposing a plurality of pipe blanksused for producing the corrugated pipe on an end part and carrying out seam welding along a circumference to form a welding seam of lap seam welding at first; and then forming the needed corrugationthrough an expansion method, and forming the welding seam in the sidewall of the corrugation during formation. According to the scheme, a traditional process is changed; bending stress born by the welding seam is low; simple welding, high efficiency, high welding seam quality and beautiful appearance are achieved; and meanwhile, a stainless steel material can be saved.

Owner:孙铭阳

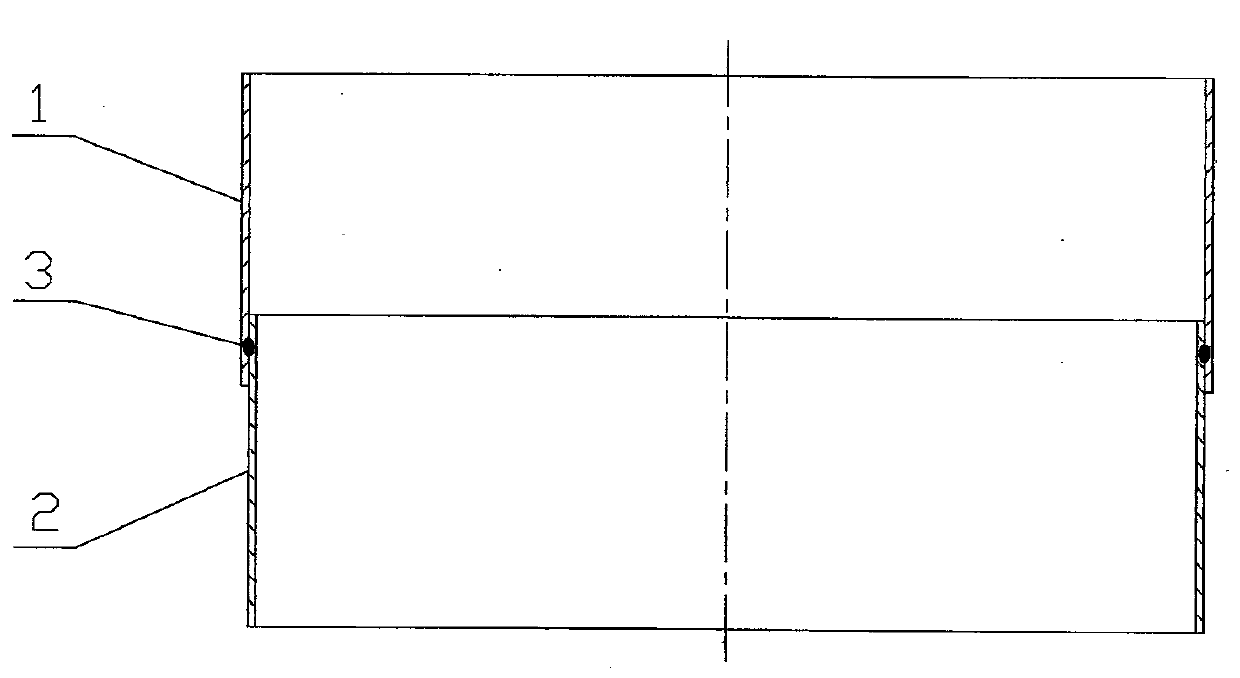

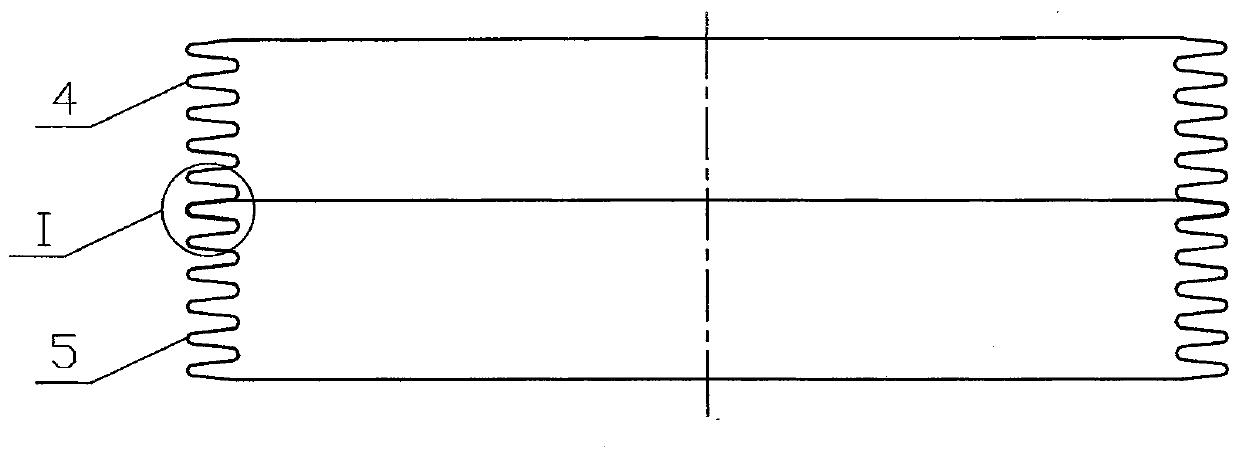

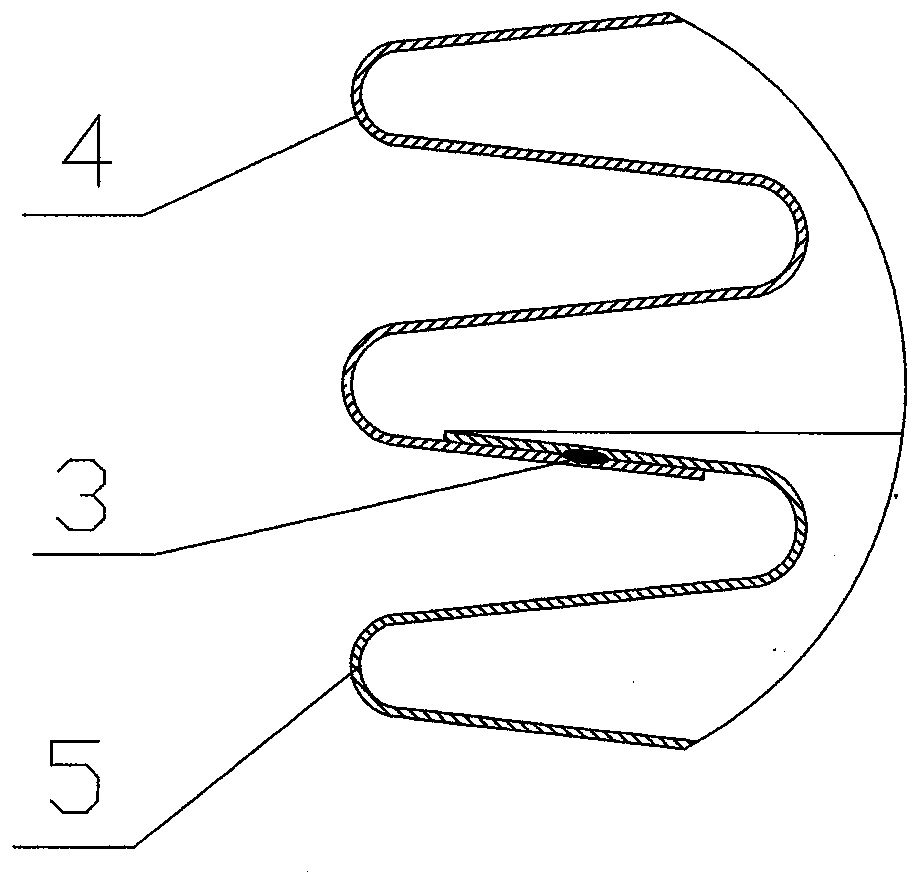

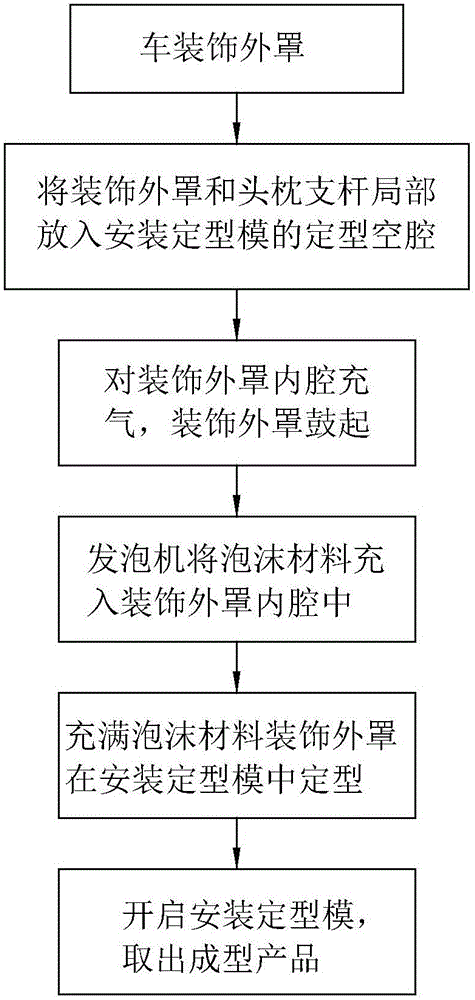

Production process of automobile headrest

ActiveCN105904641ANot easy to wrinkleSave materialDomestic articlesEngineeringMechanical engineering

The invention relates to production processes of automobile parts, in particular to a production process of an automobile headrest. The production process of the automobile headrest includes the following steps that firstly, a decorative outer cover of the automobile headrest is made of leather through turning according to the outline of a headrest core; secondly, the turned decorative outer cover is placed into a shaping cavity of an installation shaping mold, bent sections of headrest supporting rods are placed into the decorative outer cover, and the headrest supporting rods are positioned in the installation shaping mold; thirdly, an inflation device is used for inflating an inner cavity of the decorative outer cover, so that the decorative outer cover is bulged; fourthly, a spraying gun head of a foaming machine is connected with a material nozzle of the installation shaping mold, and the foaming machine fills foaming materials into the inner cavity of the decorative outer cover through the material nozzle until the decorative outer cover is full of the foaming material; fifthly, the whole decorative outer cover full of the foaming materials is shaped in the installation shaping mold for ten to thirty minutes; and sixthly, the installation shaping mold is opened, and the molded automobile headrest product is taken out. The production process of the automobile headrest has the advantages that the production process is simple, the production cost is low and product quality is easy to guarantee.

Owner:广西双英集团股份有限公司

Sheet-metal U-shaped groove labyrinth air prevention cover

The invention provides a sheet-metal U-shaped groove labyrinth air prevention cover, belonging to engine cooling systems. The sheet-metal U-shaped groove labyrinth air prevention cover is characterized in that a sheet-metal U-shaped groove outer ring structure is designed in a sheet-metal structured labyrinth air prevention cover so that a circular cylindrical surface is formed at a welding fitting surface, thereby improving the sealing performance of the labyrinth air prevention cover. The main body of the labyrinth air prevention cover is matched with the outer ring simply and reliably, thereby the welding manufacturability is improved and the appearance is attractive.

Owner:FAW GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com