Sheet-metal U-shaped groove labyrinth air prevention cover

A technology of windshield and U-shaped groove, which is applied to the arrangement of cooling combination of power unit, power unit, transportation and packaging, etc. It can solve the problems of easy deformation of plastic parts, ugly appearance, large size of windshield, etc., and achieve Simplify manufacturing time and cost, improve welding manufacturability, smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

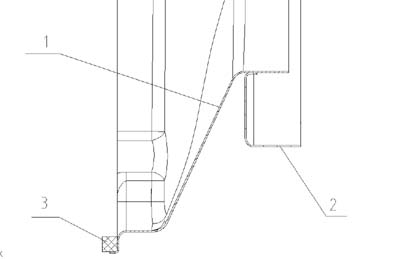

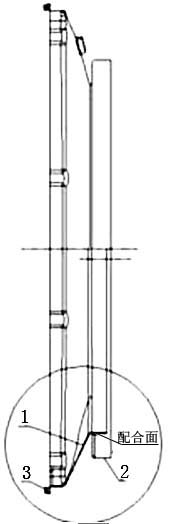

[0008] Below in conjunction with accompanying drawing, the present invention will be further described: as Figure 1-2 As shown, a sheet metal U-shaped groove labyrinth windshield is composed of a sheet metal windshield main body 1, a sheet metal U-shaped groove outer ring 2, and a sealing strip 3. It is characterized in that: the sheet metal windshield main body 1 is provided with a sheet metal U-shaped groove outer ring, and its mating surface is a ring cylinder, and the bottom of the sheet metal windshield main body 1 is provided with a sealing strip 3 . The main body 1 of the sheet metal windshield is an ordinary windshield, and the U-shaped groove outer ring 2 of the sheet metal windshield is a stamped and formed sheet metal U-shaped groove split structure, and the U-shaped groove outer ring 2 of the sheet metal windshield is assembled After being positioned on the main body 1 of the sheet metal windshield, a matching ring cylinder is formed, and the manufacturing can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com