High-integration lightweight array radar antenna skeleton

A radar antenna, highly integrated technology, used in antennas, antenna parts, antenna supports/installation devices, etc., can solve the problems of excess safety margin, material waste, low heat dissipation efficiency, etc., to meet the overall bearing capacity and plane. Stiffness, smooth and beautiful appearance, good overall sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

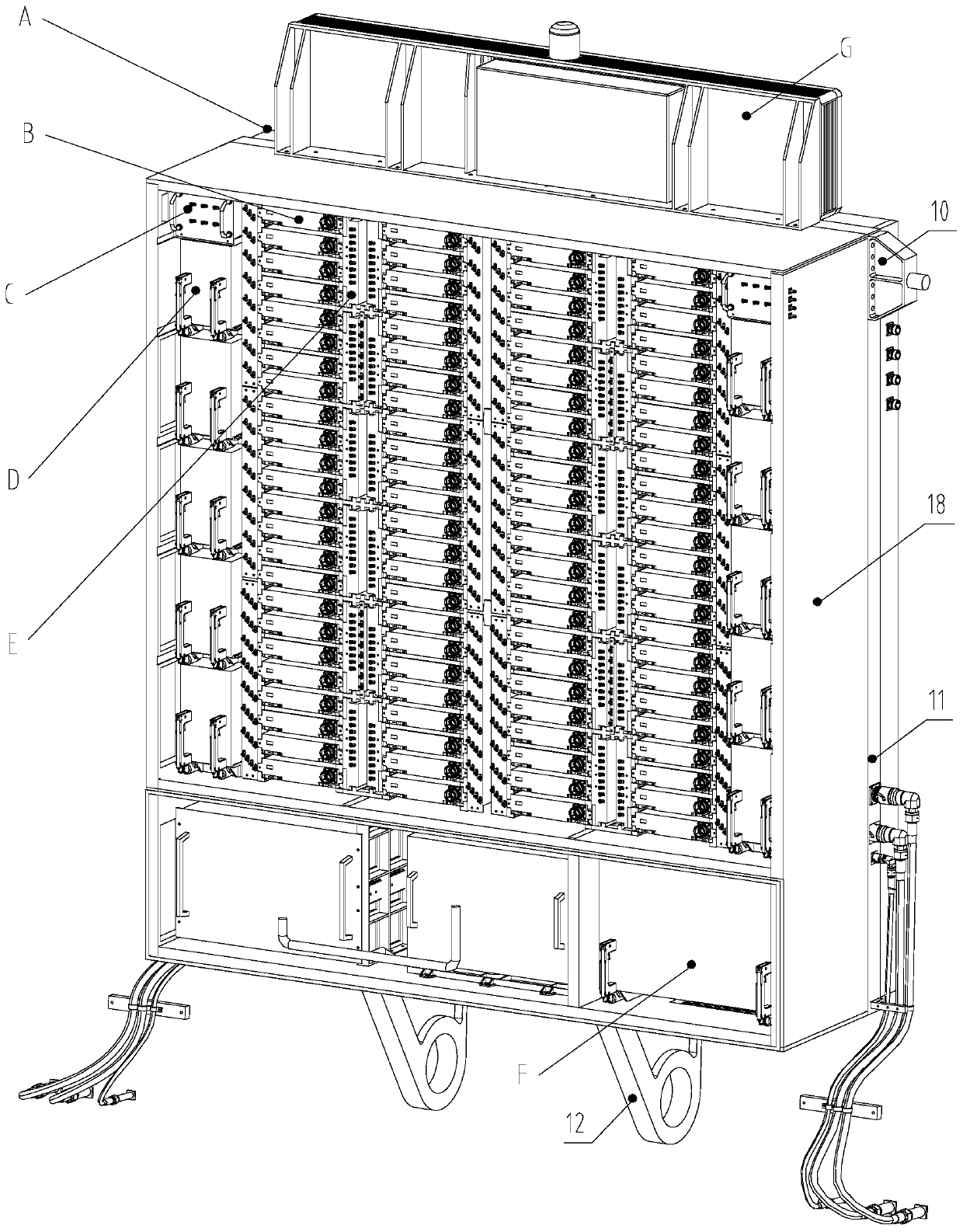

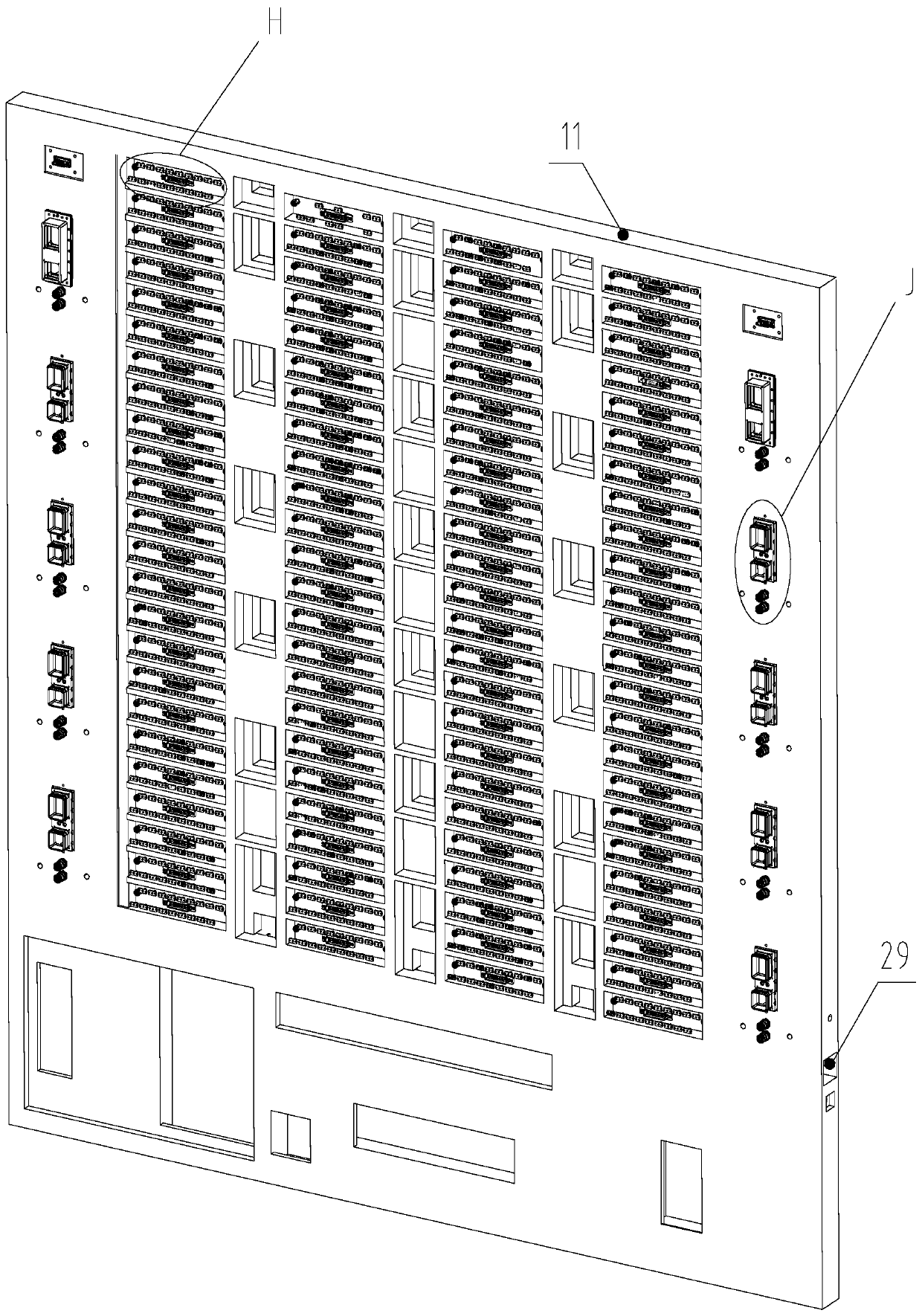

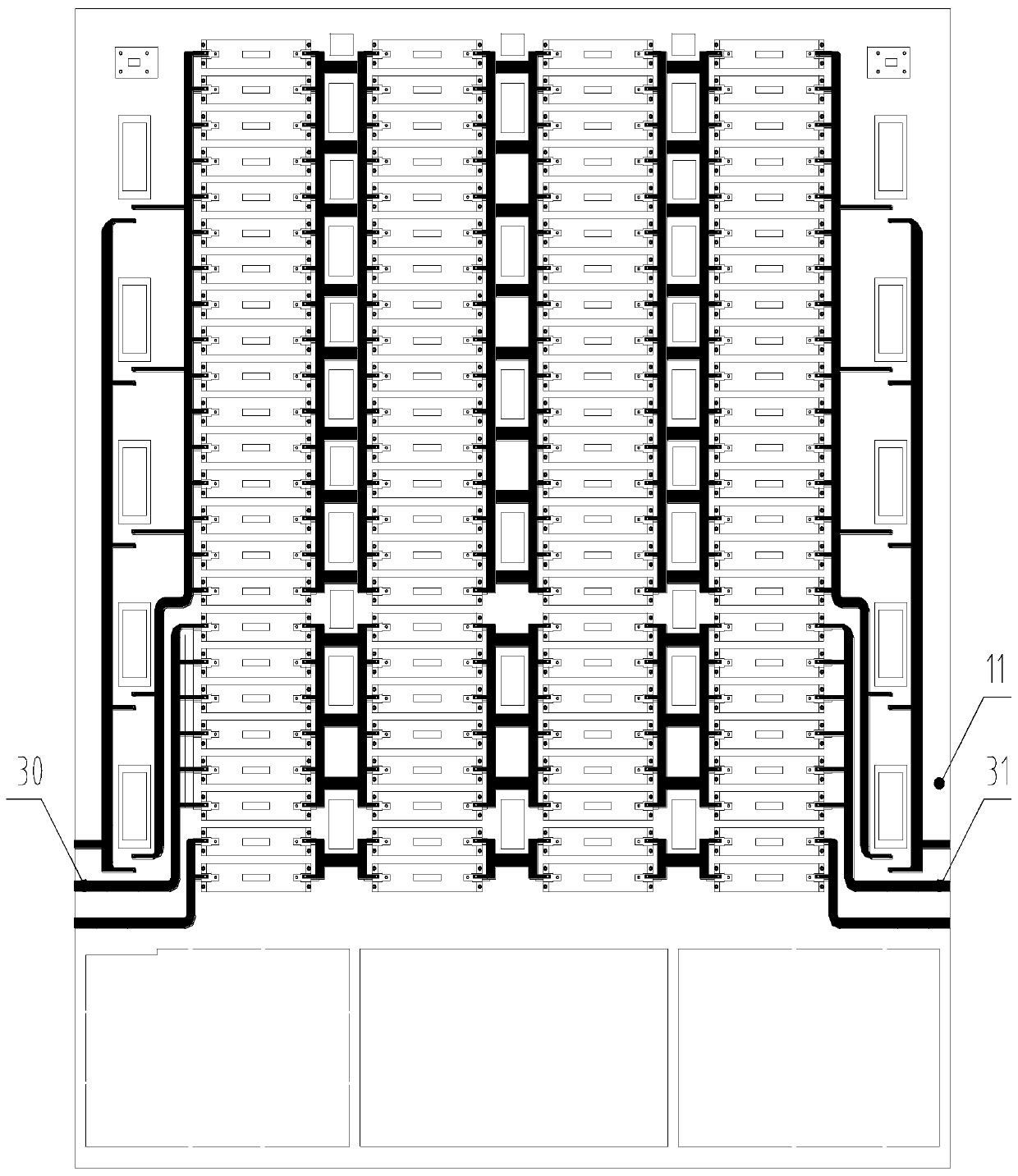

[0035] Such as Figure 1 to Figure 7 As shown, the highly integrated lightweight array radar antenna framework of the present invention includes a pitch screw support 10, a back plate 11, an antenna support 12 and an outer frame 18, an antenna longitudinal rib 19, and an antenna transverse rib 20, The bottom surface of the lower part of the backboard 11 is provided with an antenna support 12, the side of the middle part of the backboard 11 is provided with a pitch screw support 10, and the periphery of the backboard 11 is provided with an outer frame 18, which is connected to the antenna longitudinal rib 19 and the antenna transverse rib 20. Form the antenna skeleton. In the present invention, the antenna support 12 is connected to the rotating shaft on the antenna cart, the pitch screw support 10 is connected to the antenna pitch screw, and the antenna pitch screw pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com