Insulation shell manufacturing process of glass steel integrated pump station and insulation shell

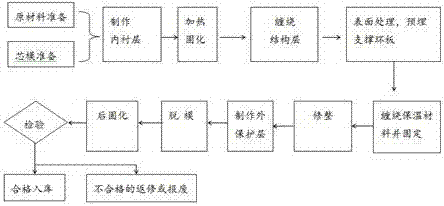

A production process, FRP technology, applied in FRP pump station insulation, FRP pump station production, FRP production and manufacturing fields, can solve the problems of uneven thickness of insulation materials, high labor intensity, low production efficiency, etc., to reduce production labor costs and on-site construction costs, avoid secondary insulation construction, and improve the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

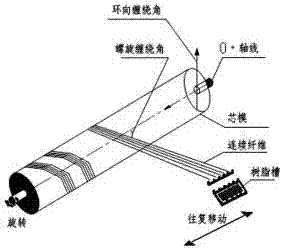

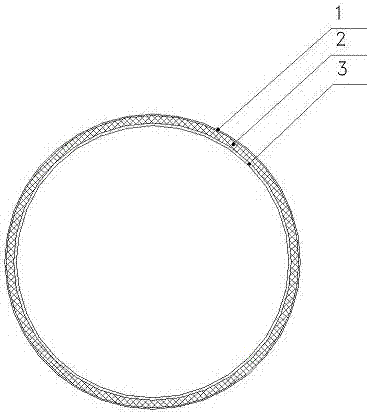

[0048] The invention adopts the methods of fixed-length winding of glass fiber reinforced plastics and manual semi-automatic winding of thermal insulation materials, so as to achieve the integral molding of thermal insulation of the casing of the glass fiber reinforced plastic pumping station. The FRP insulation shell is divided into inner shell 3, insulation layer 2, and outer shell 1. The inner and outer shells are wound on the pipe 6 mold by computer-controlled glass fibers to a fixed length, and the glass fiber reinforced plastic stopper 4 is prefabricated at the start and end of the heat preservation range; Layer 3 is made between the glass fiber reinforced plastic stoppers 4 at both ends of the inner shell, and is wound with strip-shaped insulation materials or assembled and fixed by prefabricated insulation layers. The length and thickness of insulation materials are adjusted according to design requirements. For insulation layers with thicker design thickness , can be w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com