Silicon dioxide reinforced PA66 and preparation thereof

A silicon dioxide and PA66 technology, applied in the field of silicon dioxide reinforced PA66 and its preparation, can solve the problems of difficult processing of large plastic parts, loss of nanometer effect, large specific surface area, etc., achieving good rigidity and toughness, and high addition amount. , Beautiful appearance and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

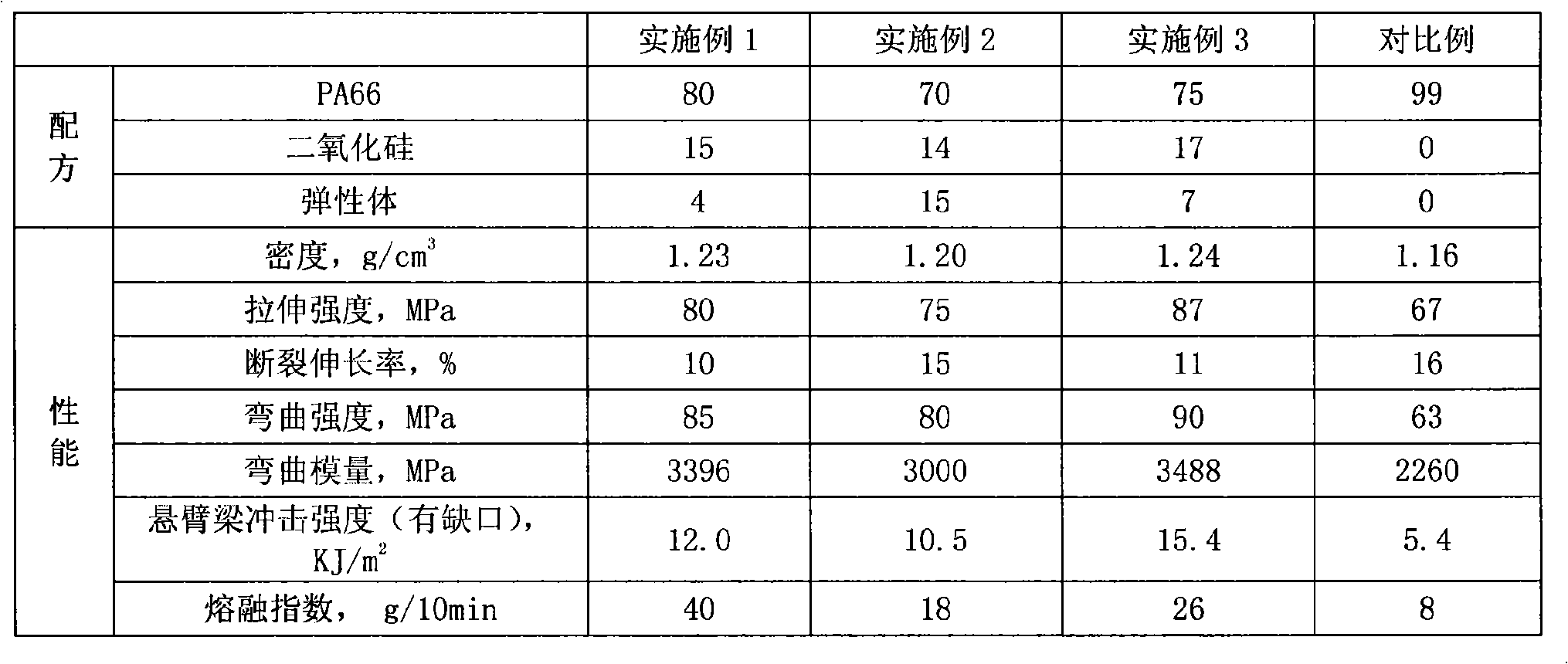

Examples

Embodiment 1

[0026] Get 15 parts by weight of PA66 slices, 15 parts by weight of silicon dioxide, 0.1 part by weight of aminopropyltriethoxysilane, 0.2 parts by weight of antioxidant 1010 and 0.2 parts by weight of antioxidant 168, 0.15 parts by weight of calcium stearate, Add it into a high-speed mixer, stir and disperse evenly, discharge the material, put it in a twin-screw extruder to melt, blend, extrude and granulate to obtain a high-filling base material. The process conditions of the extruder are: the temperature of the 1-2 zone of the twin-screw extruder is 260°C, the temperature of the 3-4 zone is 270°C, the temperature of the 5-6 zone is 265°C, and the temperature of the 7-8 zone is 260°C. The temperature is 250° C., and the screw speed is 300 rpm.

[0027] Take the high-filling base material obtained in the first step, graft EPDM with maleic anhydride, add the remaining PA66 slices and calcium stearate into a high-speed mixer, stir and disperse evenly, discharge the mater...

Embodiment 2

[0030] Get 11 parts by weight of PA66 slices, 14 parts by weight of silicon dioxide, 0.1 parts by weight of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, 0.1 parts by weight of antioxidant 1010 and 0.1 parts by weight of antioxidant 168 , N, N'-ethylenebisstearamide 0.14 parts by weight, add in the high-speed mixer and stir to disperse evenly, discharge, put it in the twin-screw extruder for melt blending extrusion granulation, obtain high filling Binder. The process conditions of the extruder are: the temperature of the 1-2 zone of the twin-screw extruder is 270°C, the temperature of the 3-4 zone is 280°C, the temperature of the 5-6 zone is 260°C, and the temperature of the 7-8 zone is 250°C. The temperature is 250° C., and the screw speed is 350 rpm.

[0031] Take the high-filling base material obtained in the first step and maleic anhydride grafted LLDPE, the remaining PA66 slices and N, N'-ethylenebisstearamide and add them to a high-speed mixer to stir ...

Embodiment 3

[0034] Get 25 parts by weight of PA66 chips, 17 parts by weight of silicon dioxide, 0.1 part by weight of aminopropyltriethoxysilane, 0.2 parts by weight of antioxidant 1010 and 0.2 parts by weight of antioxidant 168, N, N'-ethylene Add 0.22 parts by weight of bis-stearamide into a high-speed mixer, stir and disperse evenly, discharge, and place it in a twin-screw extruder to melt, blend, extrude and granulate to obtain a high-filling base material. The process conditions of the extruder are: the temperature of the 1-2 zone of the twin-screw extruder is 260°C, the temperature of the 3-4 zone is 280°C, the temperature of the 5-6 zone is 270°C, and the temperature of the 7-8 zone is 260°C. The temperature is 245° C., and the screw speed is 330 rpm.

[0035] Take the high-filling base material obtained in the first step, maleic anhydride grafted POE, the remaining PA66 slices and N, N'-ethylenebisstearamide, add them to a high-speed mixer, stir and disperse evenly, and dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com