Easily-molded environment-friendly beryllium bronze-steel bimetallic bearing material and manufacturing method thereof

A bearing material, beryllium bronze technology, applied in the field of beryllium bronze-steel bimetal bearing material and its manufacturing, can solve the problem of inability to improve bending performance, and achieve the effects of good bending performance, reduced production cost, and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

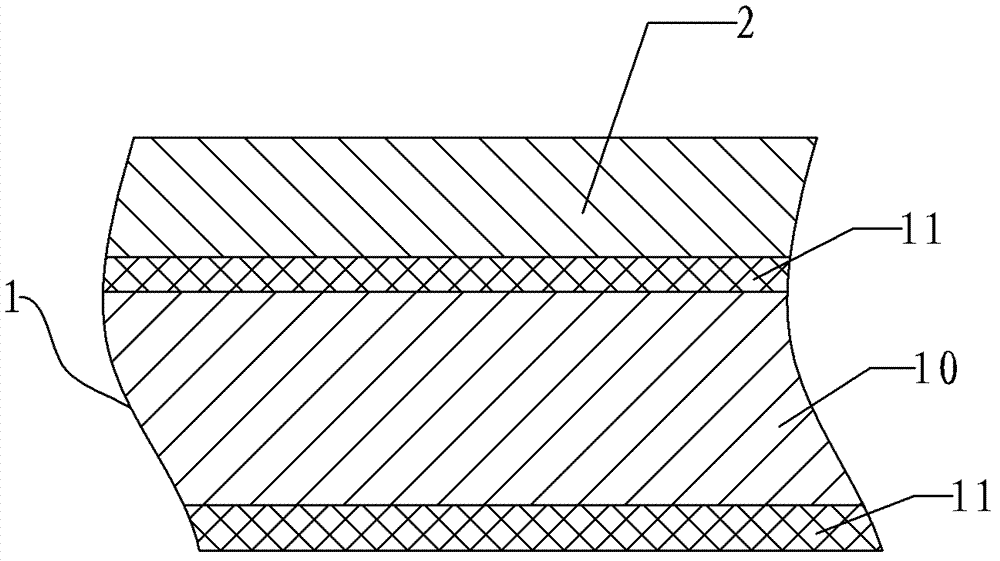

[0035] refer to figure 1 As shown, the easy-to-form environmental protection beryllium bronze-steel bimetallic bearing material of the present invention is made up of steel plate layer 1 and alloy layer 2, and described steel plate layer 1 and alloy layer 2 are upper and lower two layers, and described steel plate layer 1 is made of base layer The steel plate 10 is composed of a copper plated layer 11 on the surface of the steel plate 10, the material of the steel plate 10 is low-carbon high-quality carbon steel with a carbon content of less than 0.2%, and the thickness of the copper plated layer 11 is 0.30 to 1.00 mm. The material of the alloy layer 2 is a beryllium bronze alloy formed by sintering beryllium bronze alloy powder, and the chemical composition of the beryllium bronze alloy powder is calculated by weight percentage: 2% to 5% beryllium, 5% to 7% tin, and 7% to 8% zinc , the balance is copper, and the particle size of the beryllium bronze alloy powder is less than ...

Embodiment 2

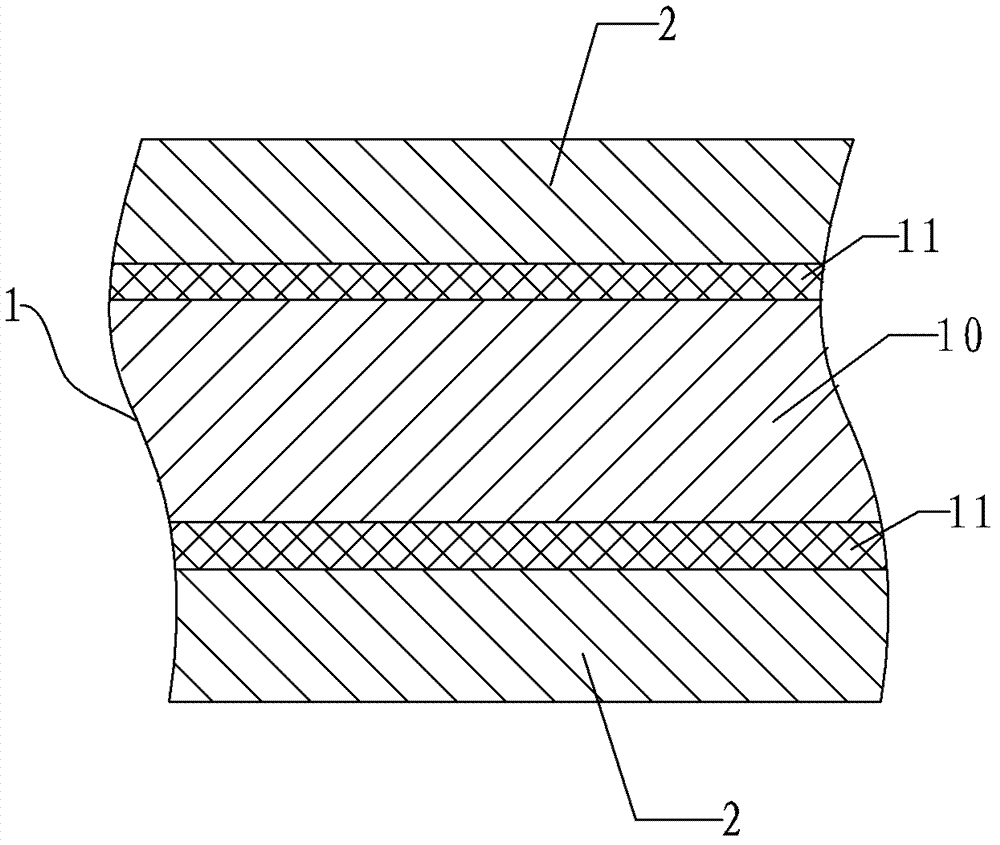

[0037] refer to figure 2 As shown, the easy-to-form environment-friendly beryllium bronze-steel bimetal bearing material of the present invention is composed of a steel plate layer 1 and an alloy layer 2, and the steel plate layer 1 and the alloy layer 2 are two layers inside and outside, wherein the steel plate layer 1 is located at The inner layer, the alloy layer 2 is located in the outer layer, the steel plate layer 1 is composed of the steel plate 10 of the base layer and the copper plated layer 11 on the surface of the steel plate 10, and the material of the steel plate 10 is low-carbon high-quality carbon steel with a carbon content of less than 0.2%. , the thickness of the copper plating layer 11 is 0.30 ~ 1.00mm, the material of the alloy layer 2 is beryllium bronze alloy sintered beryllium bronze alloy powder, the chemical composition of the beryllium bronze alloy powder is calculated as: 2-5% of beryllium, 5-7% of tin, 7-8% of zinc, and the balance of copper, the p...

Embodiment 3

[0040] The production material specifications are: total thickness 2.5×alloy layer width 120mm, easy-to-form environmental protection beryllium bronze-steel bimetallic bearing material plate with alloy layer thickness 0.5mm.

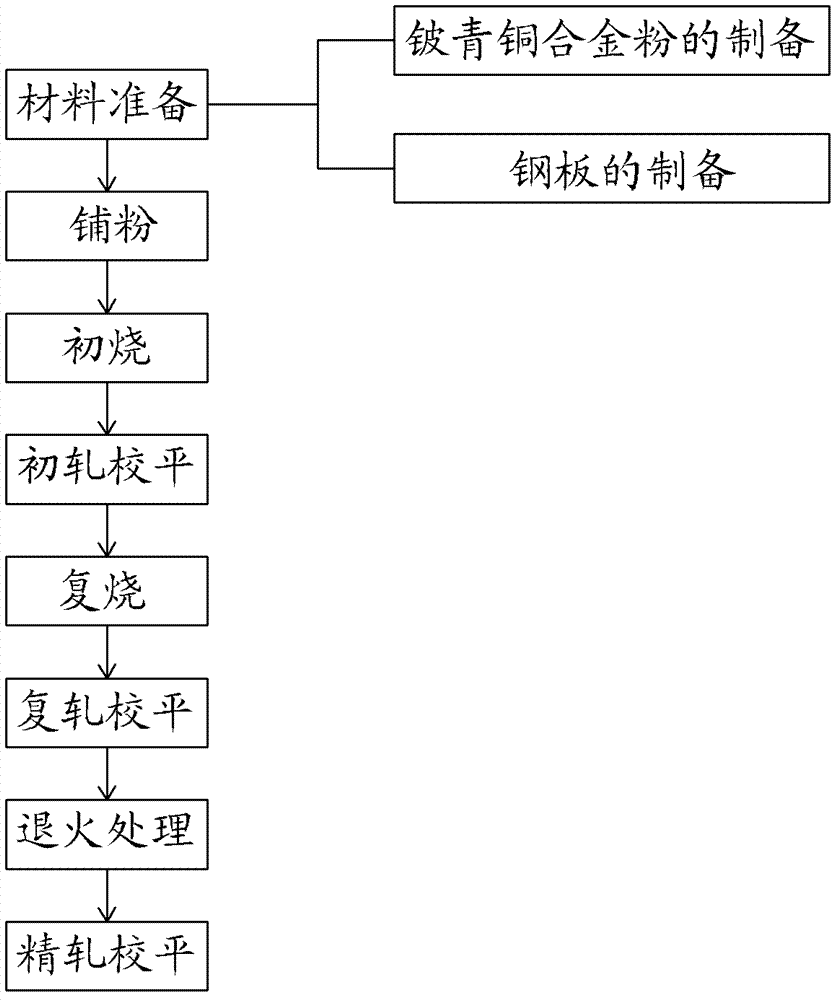

[0041] refer to image 3 shown, including the following steps:

[0042] Step 1, material preparation, including the following two steps:

[0043] A, the preparation of beryllium bronze alloy powder;

[0044] According to the percentage by weight, it is 2% beryllium, 5% tin, 7% zinc and the balance is copper for accurate weighing and proportioning. After mixing and melting, it adopts a fully enclosed high-pressure water atomization method to make beryllium bronze alloy powder, and then sieves to obtain granules. Beryllium bronze alloy powder with diameter less than 0.1mm;

[0045] B, the preparation of steel plate;

[0046] Cut the low-carbon high-quality carbon steel plate with a carbon content of less than 0.2% into 2.5×126×625mm (thickness×width×leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com