Die for valve core framework coated insulating silicone and using method thereof

A technology of insulating silicone and skeleton, applied in the direction of coating, etc., can solve the problems of rubber waste edge on the rubber covering surface, uneven thickness of insulating silicone rubber layer, etc., and achieve consistent vulcanization degree, firm and consistent positioning of the skeleton, and consistent thickness of the rubber covering layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

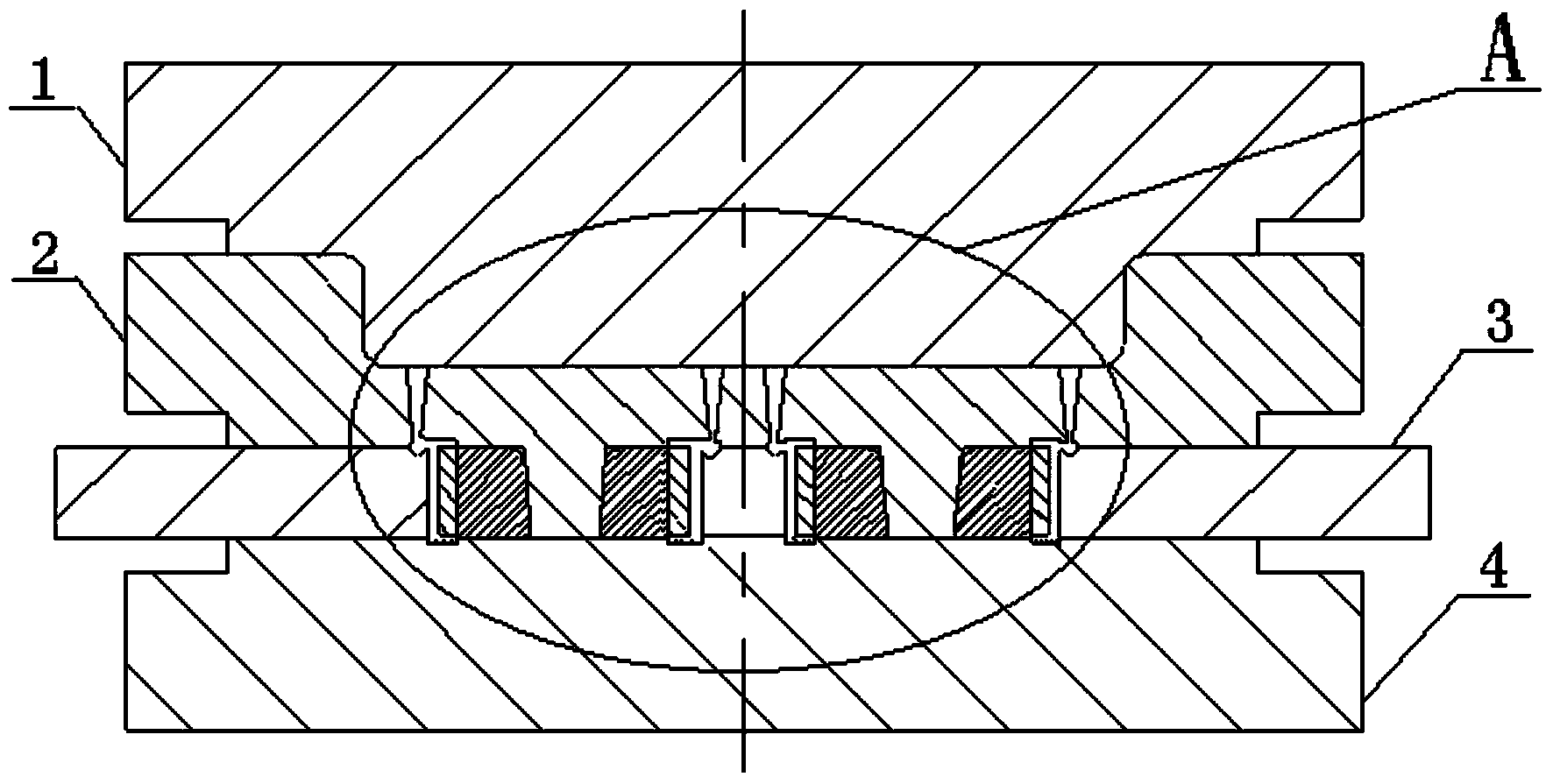

[0026] like figure 1 , The mold of the spool skeleton covered with insulating silica gel under the present embodiment, it includes the injection head 1, the upper mold 2, the middle mold 3, the lower mold 4 and the sliding mold core 8 sequentially from top to bottom. The number of molds covered with insulating silica gel for the valve core frame is 4 pieces, the mold size is 300X300, and it is produced by a 200T molding machine.

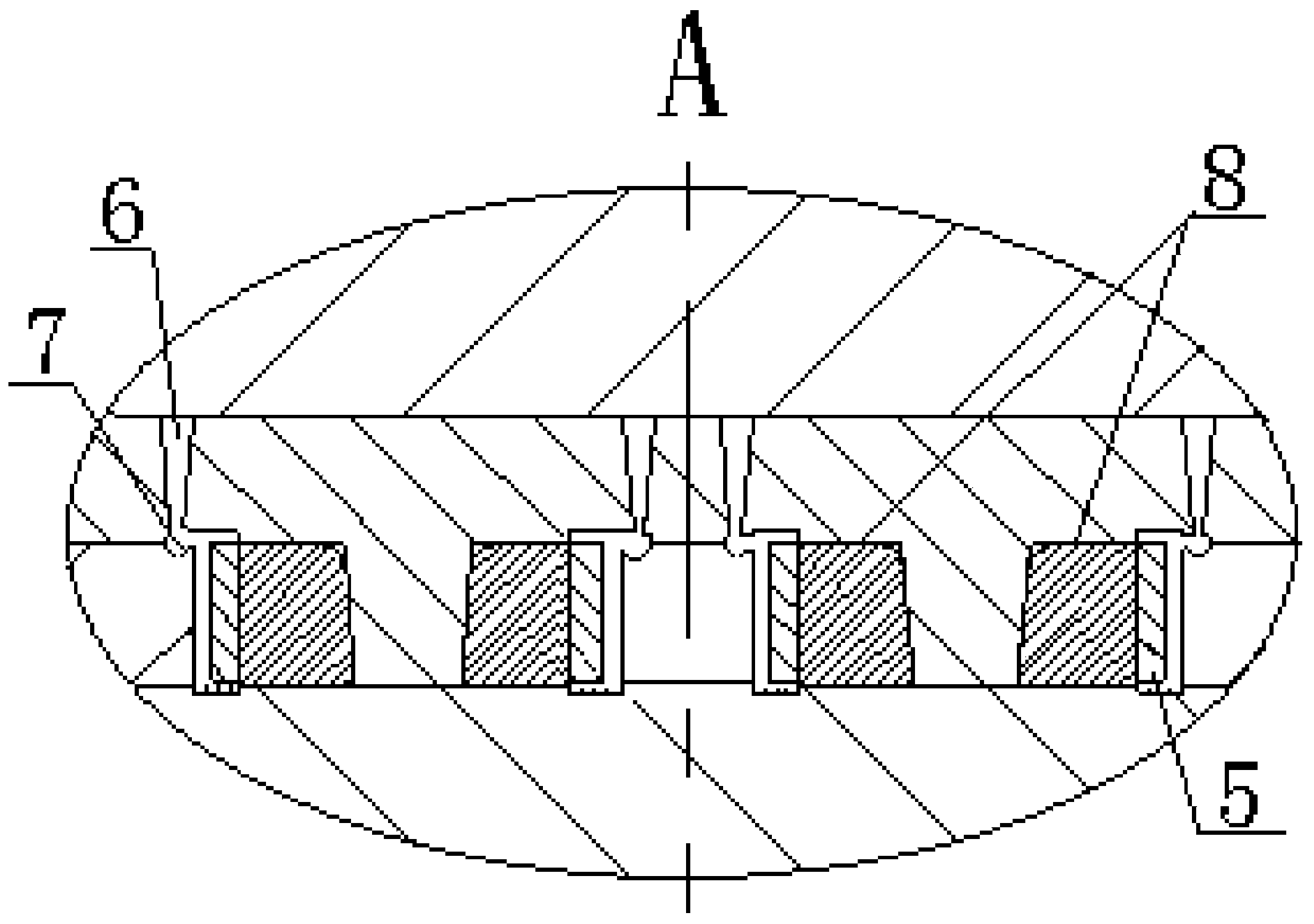

[0027] like figure 2 , the sliding mold core 8 is assembled on the lower mold 4 and is located in the mold cavity of the middle mold 3, the valve core skeleton 5 is located between the sliding mold core 8 and the inner wall of the mold cavity of the middle mold 3, and the upper surface of the lower mold 4 corresponds to the valve core skeleton 5 is provided with granular protrusions to ensure that the lower botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com