Manufacturing process of evaporator

A manufacturing process and evaporator technology, applied in the field of evaporator manufacturing process, can solve the problems of complex manufacturing process, low production efficiency and high production cost, and achieve the effects of high heat exchange efficiency, improved production efficiency and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

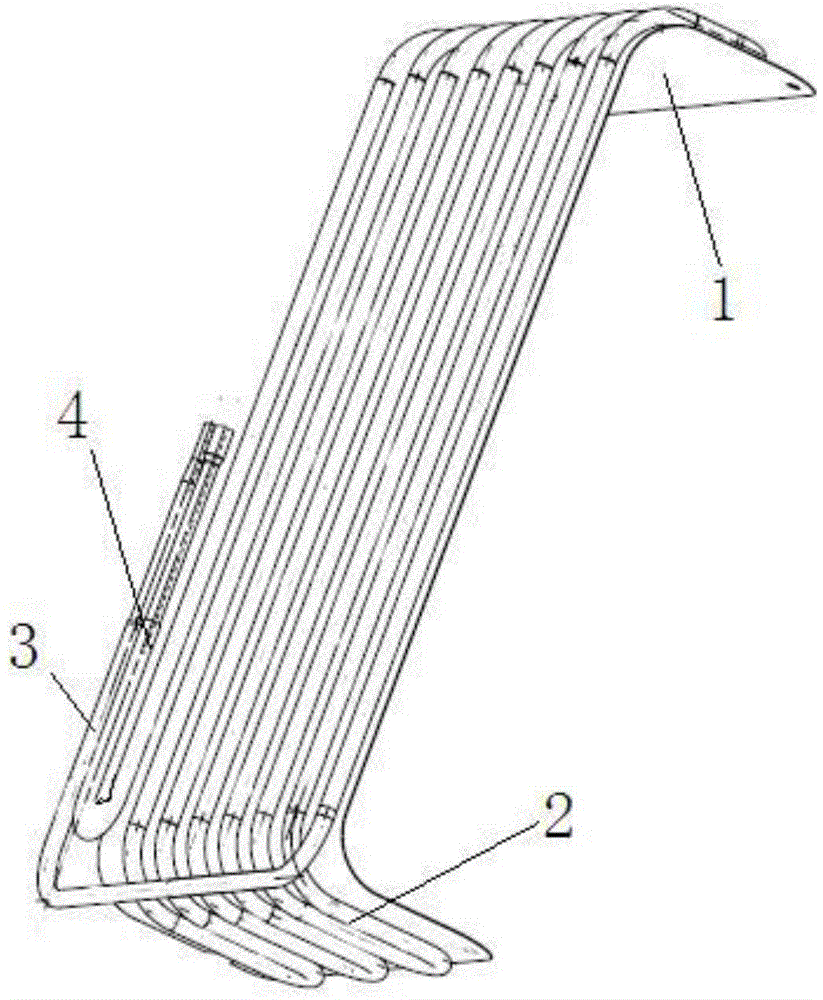

[0018] An evaporator as shown in the figure, its specific manufacturing process includes the following steps:

[0019] The first step is to design the structure of the aluminum plate 1 according to the heat transfer requirements of the refrigerator and the display cabinet and the product installation size, and design the specific distribution of the aluminum tubes on the aluminum plate 1 according to the diameter of the aluminum tube 2;

[0020] In the second step, the aluminum tube 2 is bent into a snake-shaped aluminum tube formed by several curved arc tubes and straight tubes;

[0021] The third step is to press the snake-shaped aluminum tube into a flat aluminum tube, and use a press to press it into a flat aluminum tube. In this embodiment, the diameter of the snake-shaped aluminum tube is 8mm. 2mm, so that the flat aluminum tube has enough contact area with the aluminum plate 1;

[0022] The fourth step is to coat the brazing flux on the pressed flat aluminum tube, pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com