Furniture wall surface panel installation structure

A technology for installing structures and walls, which is applied in the direction of furniture connection, connecting components, mechanical equipment, etc. It can solve the problems of long installation time, high labor intensity, and inconvenient installation, and achieve the effect of convenient and fast installation, flat and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

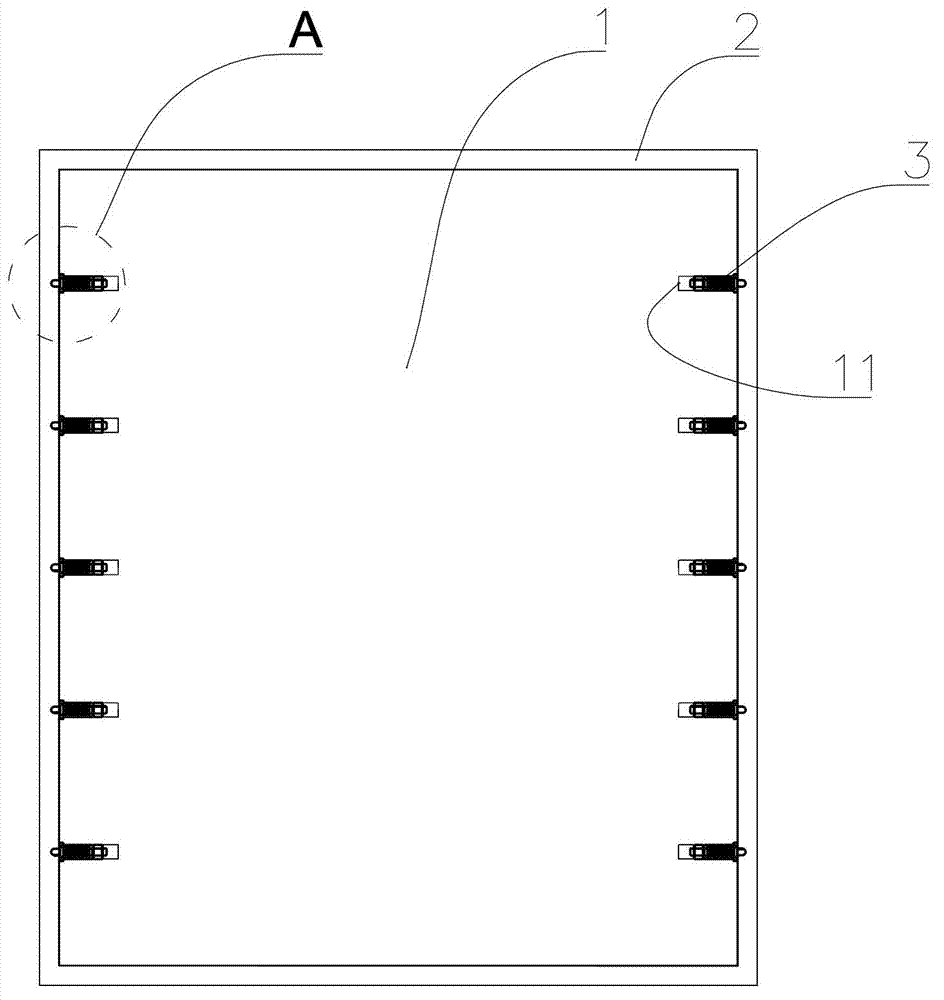

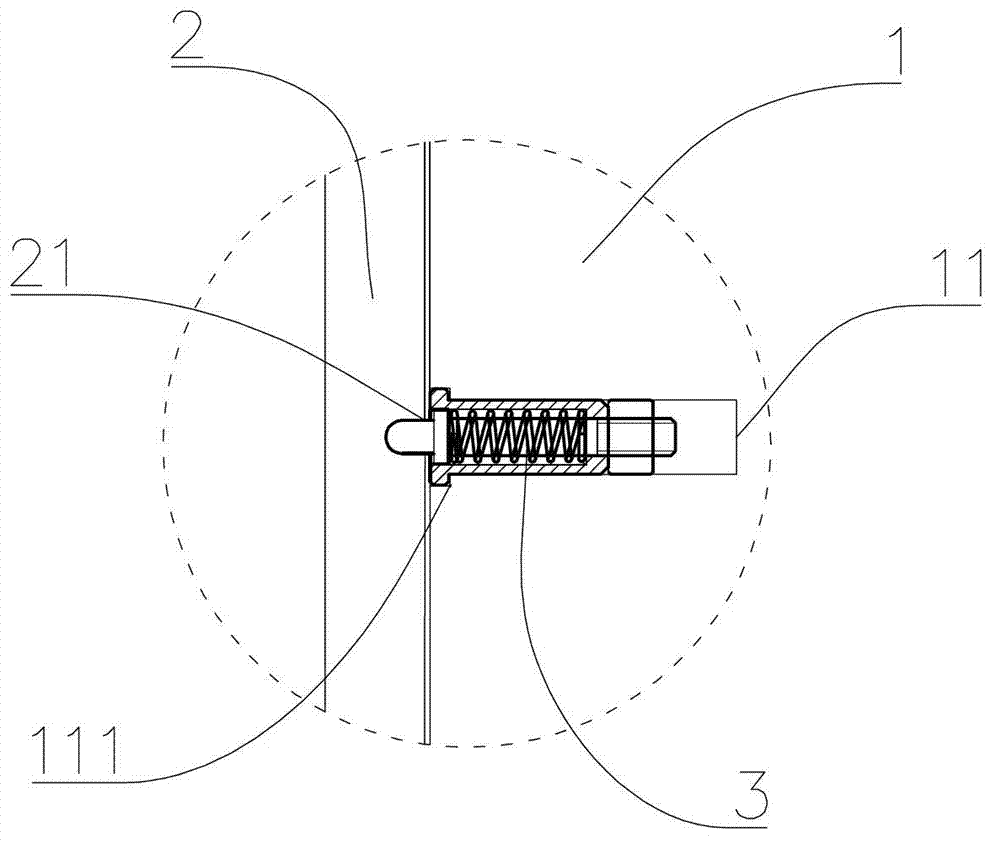

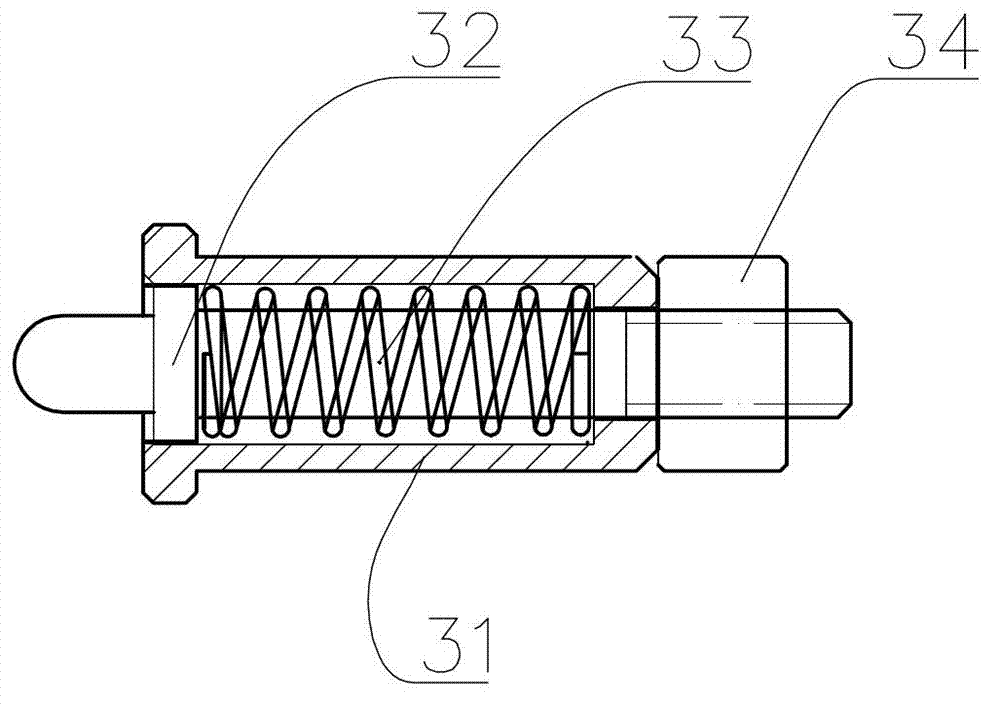

[0015] according to Figure 1 to Figure 5 As shown, the panel installation structure of a furniture wall described in this embodiment includes a frame 2 made of metal, and a wooden board 1 that matches the size of each wall formed by the frame 2. The outer peripheral side wall of the wooden board 1 is provided with Connecting holes 11, connectors 3 are provided in the connecting holes 11, clamping holes 21 are provided on the frame 2 corresponding to the positions of each connecting hole 11, and the clamping holes 21 cooperate with the outer ends of the connectors 3 to fix the wooden board 1 to the frame 2 Above; the connecting piece 3 includes a housing 31, a clamping shaft 32 slidingly arranged in the housing 31, and a push clamping shaft 32 is arranged between the clamping shaft 32 and the housing 31 to protrude toward the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com