A prefabricated shear wall and wall-beam connection structure with edge restraint components

A technology of constraining components and connecting structures, applied to building components, walls, building structures, etc., can solve problems such as complex wall-beam connection forms, poor seismic energy consumption characteristics, and difficult construction, so as to improve internal and lateral resistance, The effect of improving energy dissipation capacity and improving seismic energy dissipation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

[0037] A prefabricated shear wall and wall-to-beam connection structure with edge restraint members, comprising shear walls and beams 10 prefabricated from concrete,

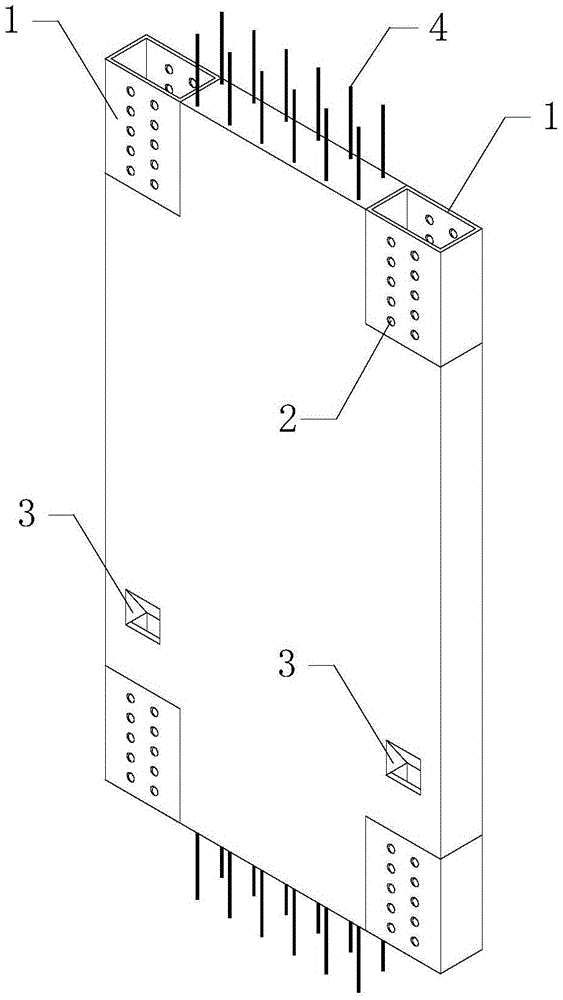

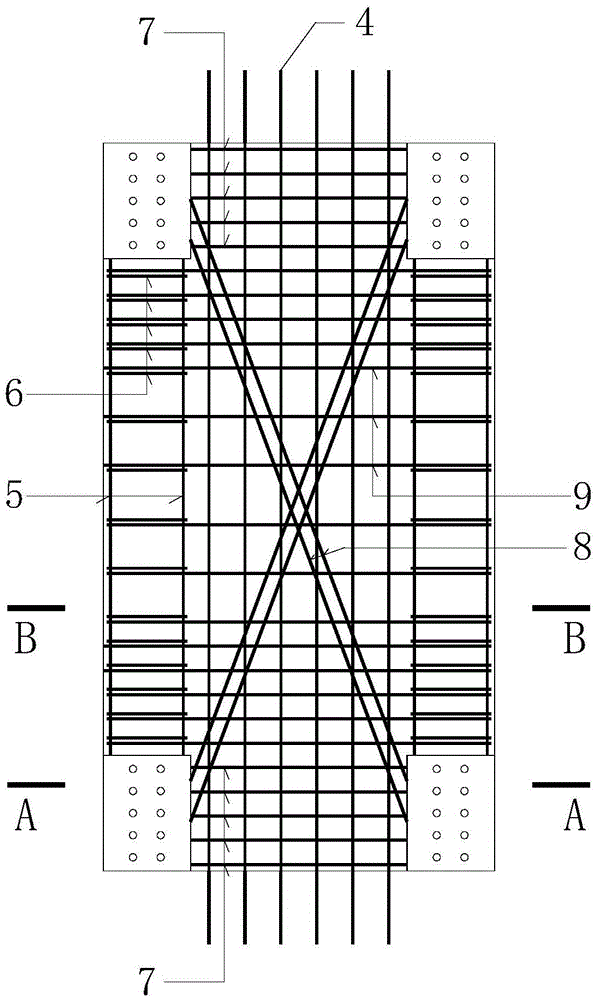

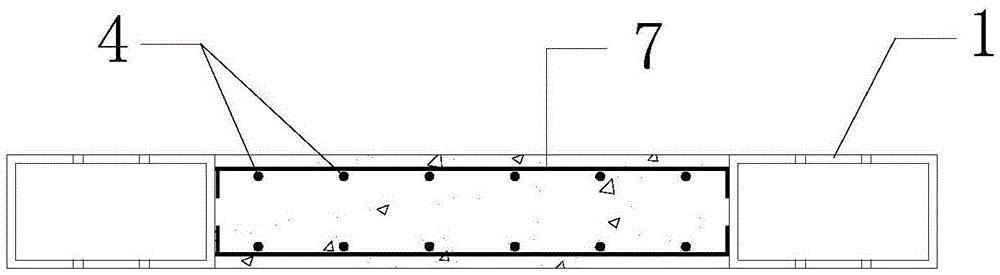

[0038] Such as figure 1 As shown, the shear wall includes a wall body, the four corners of the wall body are rectangular missing corners, the middle of the wall body is provided with a protruding steel bar 4, and the protruding steel bar 4 runs through the wall body longitudinally and extends from the upper and lower ends of the wall body. The specific length and specifications of the protruding steel bars 4 need to be determined according to the specifications of the shear wall and the beam 10; on the missing corners of the rectangle, there are respectively adapted hollow rectangular steel pipes 1, and the rectangular steel pipes 1 are welded by ordinary steel plates , the specific size of the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com