Mortise and tenon type side wall structure of all-aluminum alloy vehicle

An aluminum alloy and mortise-and-mortise technology, which is applied to vehicle components, superstructures, and subassemblies of superstructures, can solve problems such as difficult changes in the arc shape of corners, high requirements for assembly technology, and large dimensions of arc-shaped connecting beams. , to achieve the effect of avoiding interspersed assembly, smooth and beautiful appearance, and improving the rigidity of the side wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

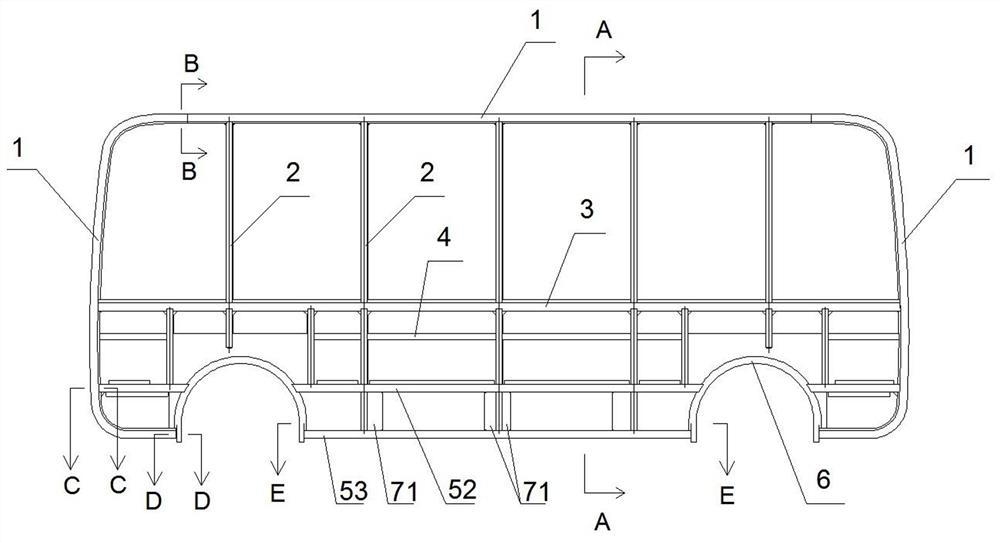

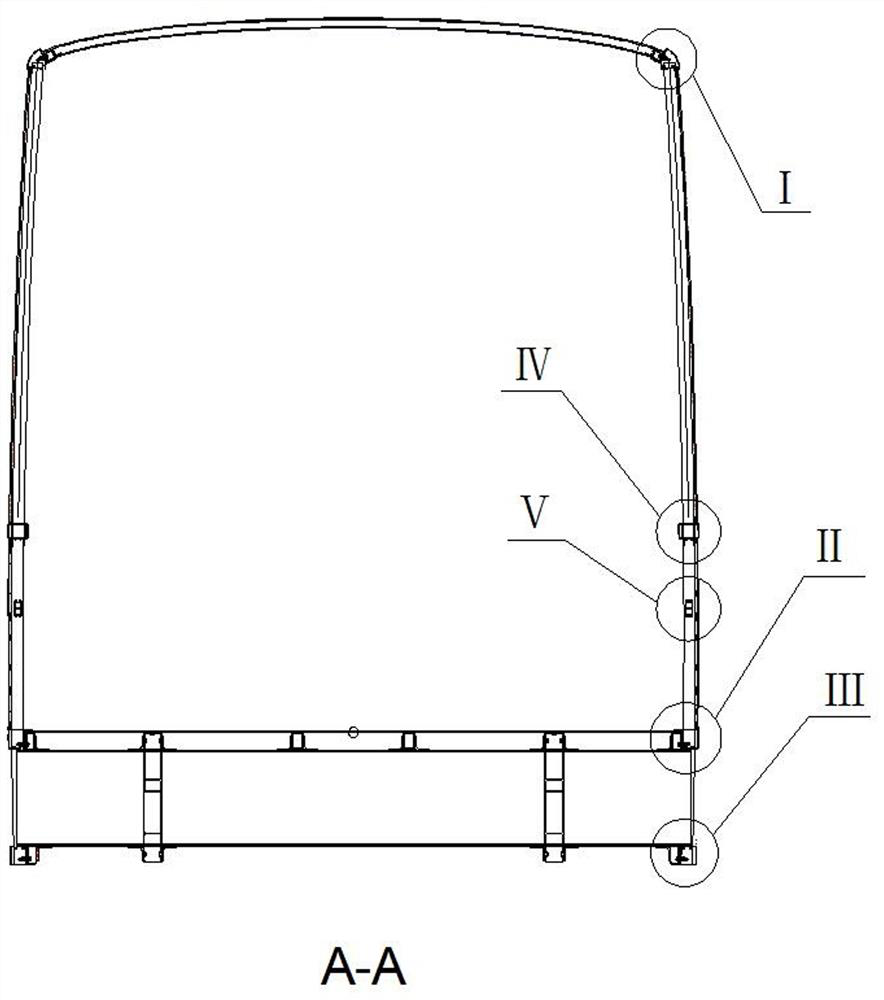

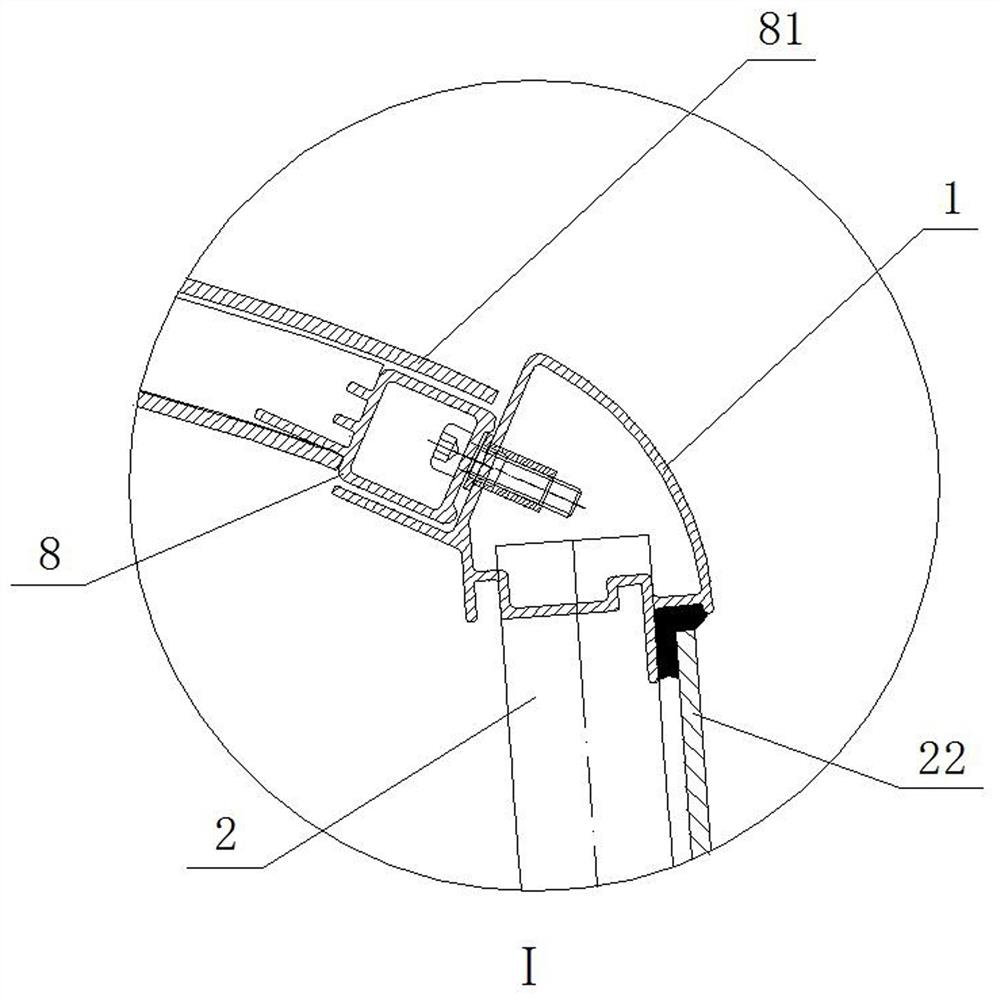

[0046] An all aluminum alloy vehicle mortise and tenon type side wall structure, the side wall includes a side wall beam 1, a lower bottom beam 53 and a wheel eyebrow frame 6 to form an outer contour, and inside the outer contour are arranged a number of waistline beams 3 and a number of vertical columns 2. The glass 22 installation area is between the side wall beam 1 and the waistline beam 3, and the aluminum alloy profile panel 23 is installed in the area between the floor bottom beam 52 and the waistline beam 3;

[0047] Below the waistline beam 3, there is also a reinforcing beam 4 connected in parallel and transversely. The reinforcing beam 4 and the column 2 are connected by interspersed mortise and tenon joints.

[0048] The profile panel 23 is a horizontal strip-shaped thin-walled aluminum profile plate, the back of the profile panel 23 is provided with transverse I-shaped ribs, and the upper and lower ends of the profile panel 23 are provided with splicing notches and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com