Production process of automobile headrest

A technology of automobile headrest and production technology, which is applied in the field of production technology of auto parts, can solve problems such as difficult product quality assurance, increased production cost, complicated production process, etc., and achieves easy product quality assurance, low production cost, and high production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

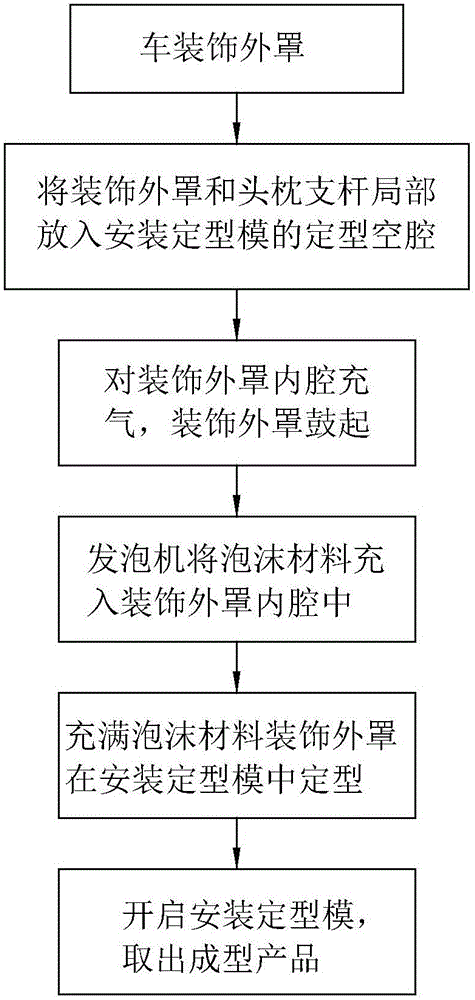

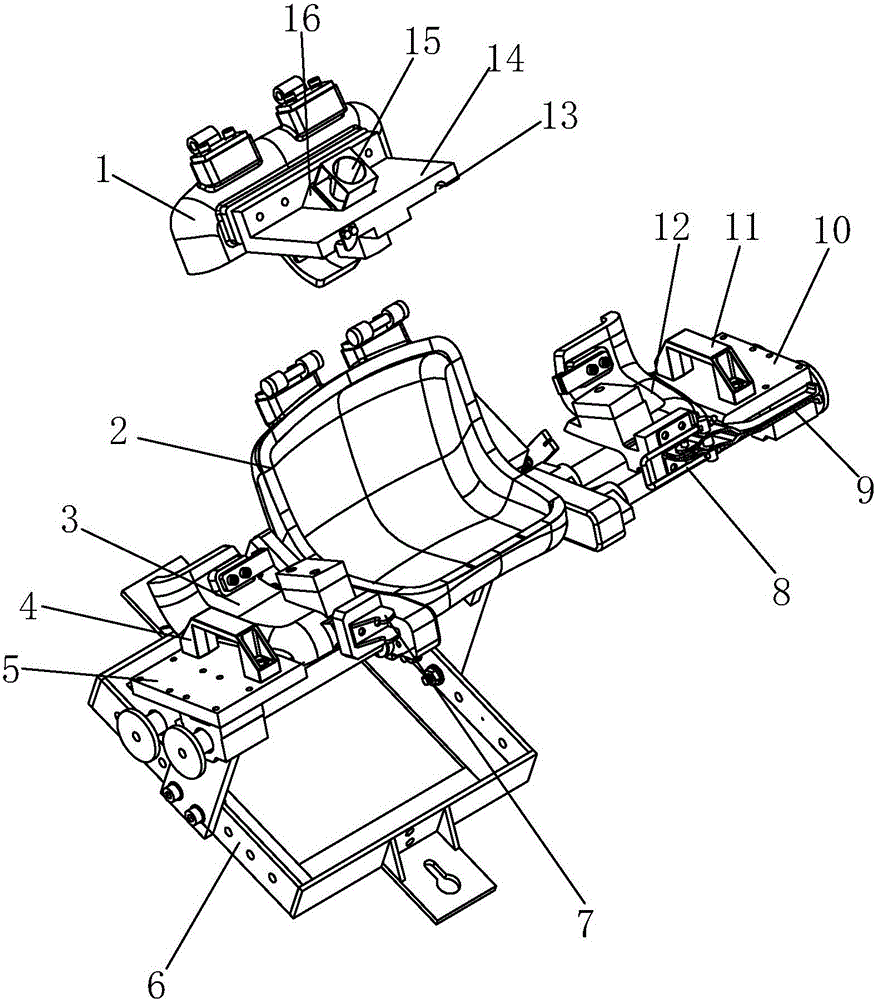

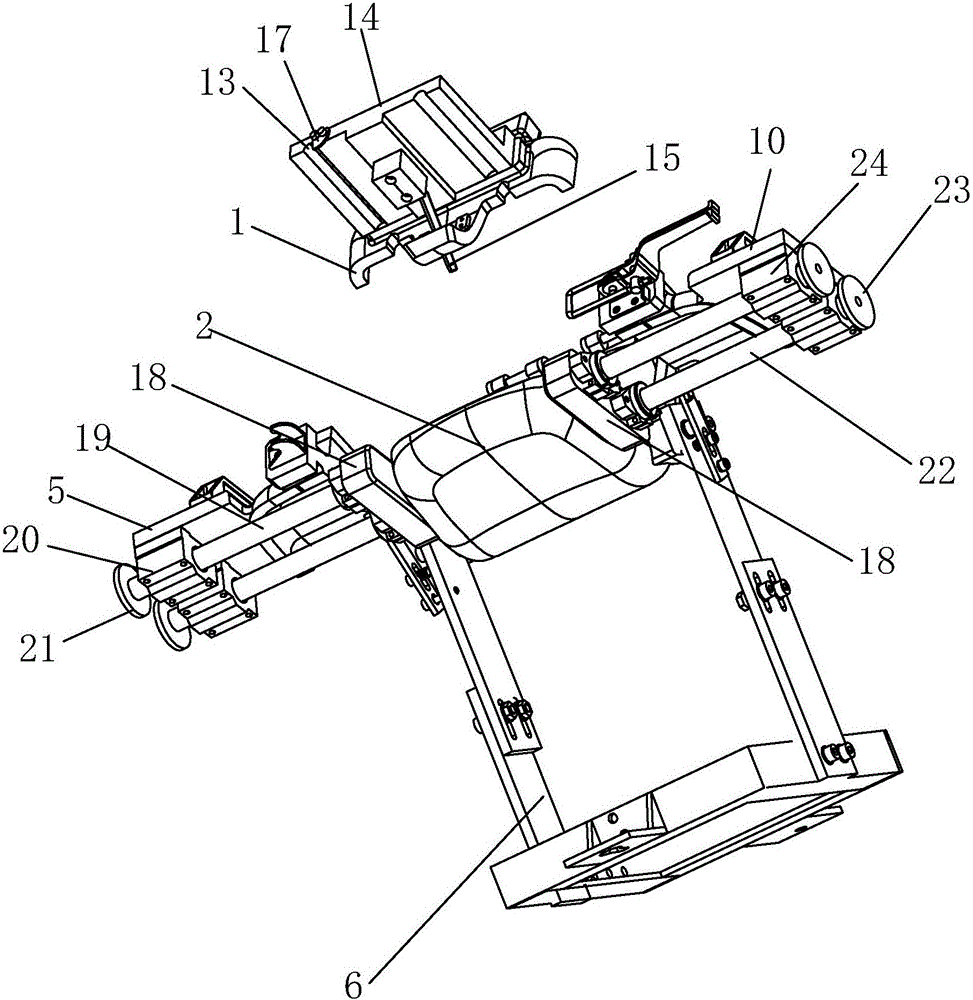

[0025] Such as figure 1 As shown, the production process of a kind of automobile headrest of the present invention comprises the following steps: (1) car the decorative outer cover of the automobile headrest according to the outline of the headrest core with leather material; (2) put the decorative outer cover of the car Into the shaping cavity of the installation shaping mold, the bent part of the headrest strut is put into the decorative outer cover, and the headrest strut is positioned in the installation shaping mold; (3) The inner cavity of the decorative outer cover is inflated by an inflatable device, Make the decorative cover bulge; (4) Connect the spray gun head of the foaming machine to the material nozzle installed on the setting mold, and the foaming machine will fill the foam material into the inner cavity of the decorative cover through the material nozzle until the decorative cover is full. foam material; (5) Let the decorative outer cover filled with foam mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com