Frame type oil press for the titanium sponge knife for crushing

A frame-type hydraulic press technology, applied in the field of hydraulic presses, can solve problems such as short service life of guide sleeves and seals, poor verticality of oil cylinder operation, large bending deformation of columns, etc., to reduce seal eccentric wear, increase verticality, and stress variation range small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

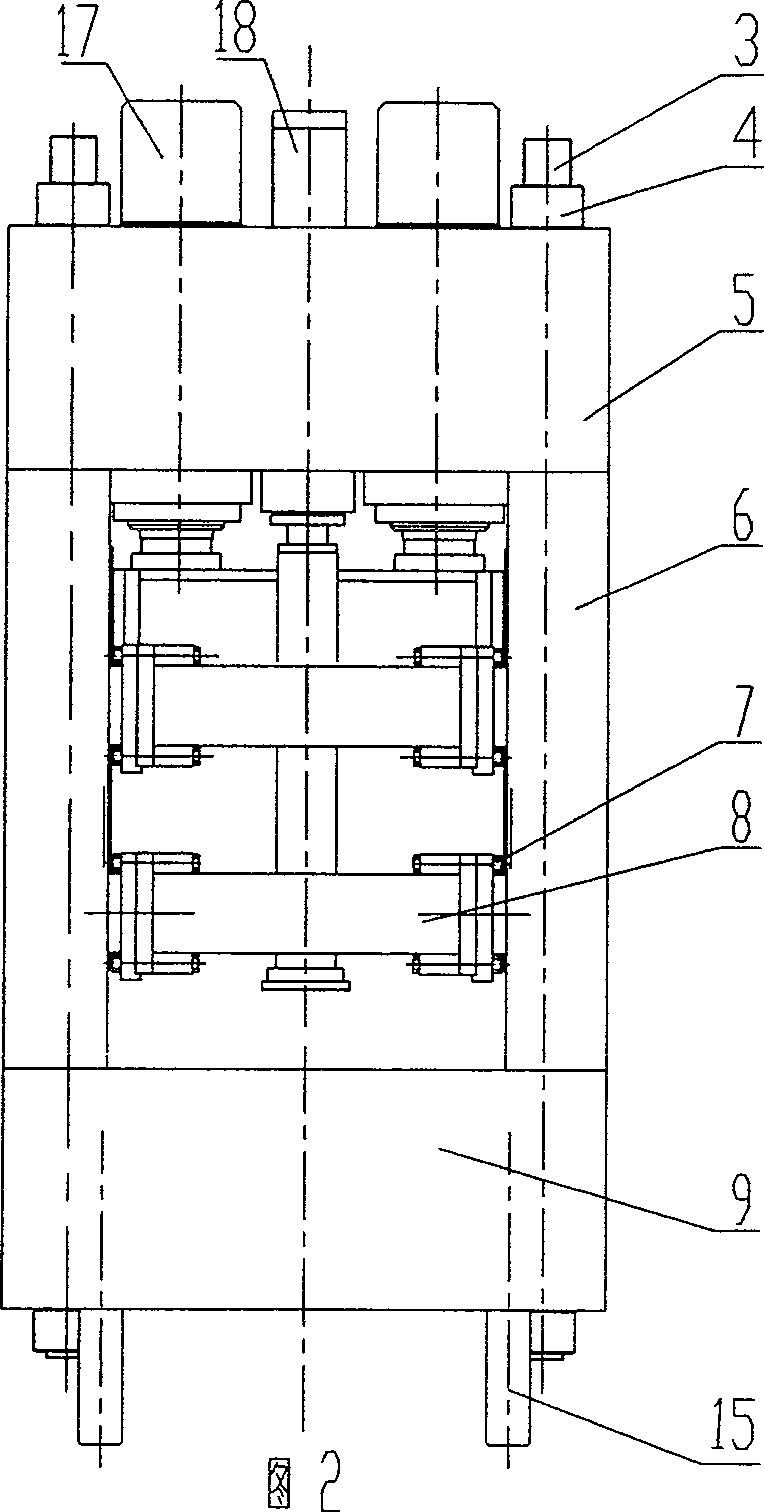

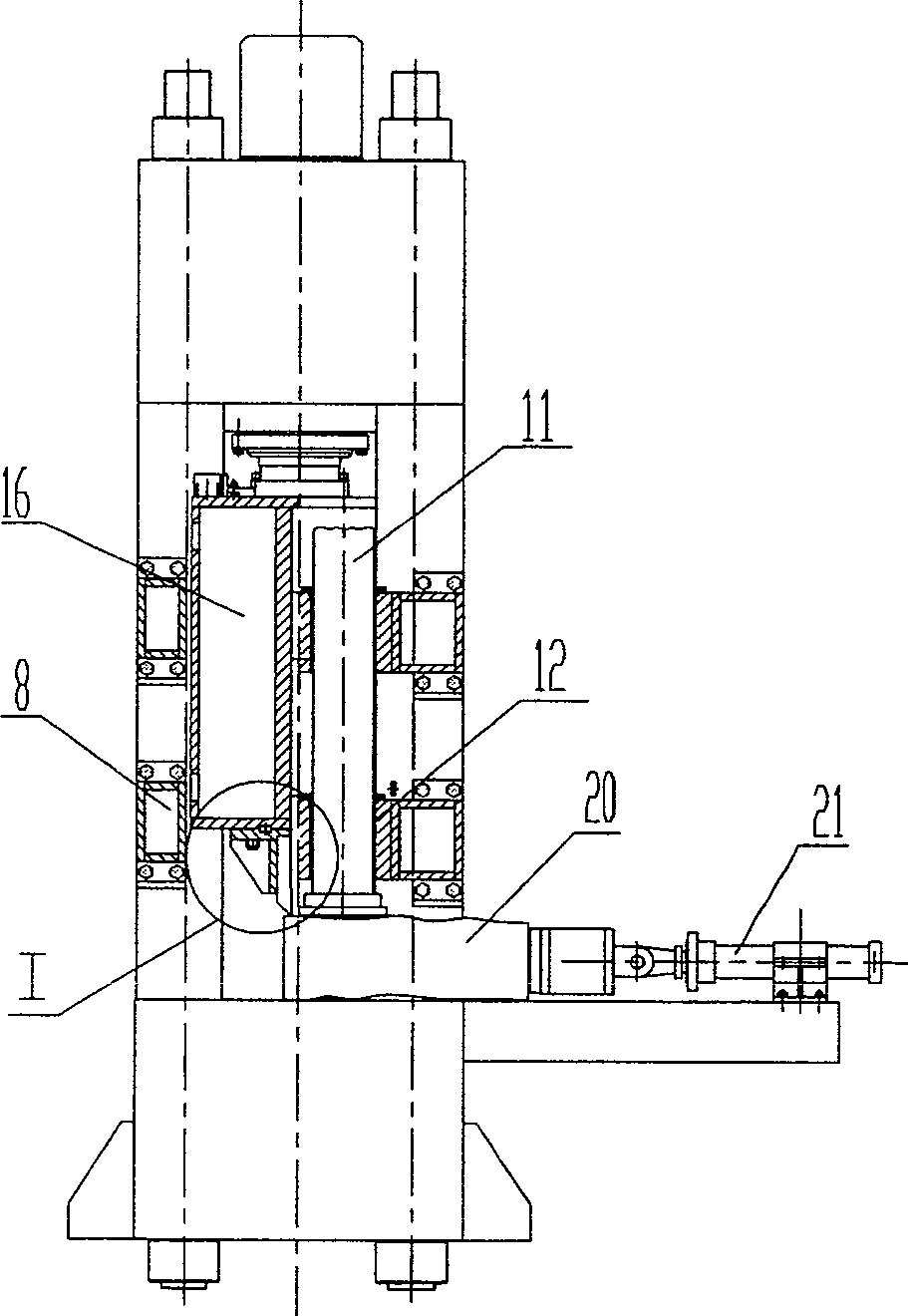

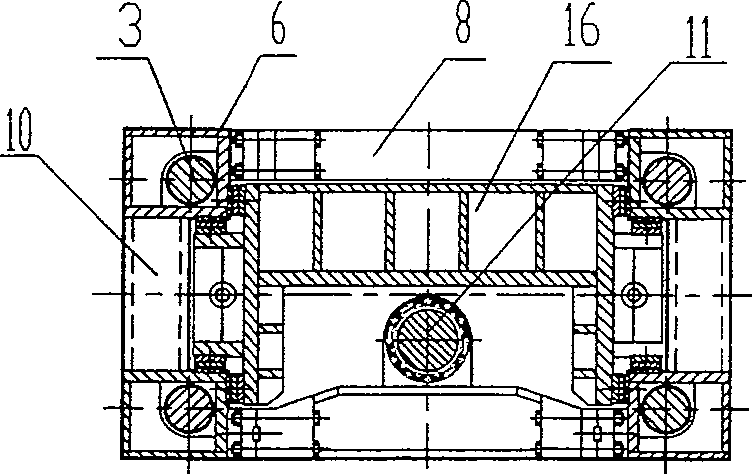

[0016] As shown in Figures 2, 3, and 4, a frame-type hydraulic press for knife-cutting and crushing of titanium sponge consists of an upper beam 5, four frames 6, and a lower beam 9 pre-tightened by four pull rods 3 and nuts 4. In the closed stress frame, in the prestressed frame, the two frames 6 on both sides are welded together by the connecting frame 10, and the upper and lower connecting beams 8 are connected by bolts 7 between the two welded bodies, so that the four The frame 6 forms a whole; two cutting cylinders 17 and one pressing cylinder 18 are arranged asymmetrically on the upper beam 5, the plunger of the cutting cylinder 17 is connected to the slider 16, and the cutter 14 is connected to the slider 16, The piston of the pressure cylinder 18 is connected with the pressure rod 11; the lower beam 9 is equipped with a return cylinder 15 and a push cylinder 21. The frame 6 has a rectangular cross-section, and its bending resistance is better than that of a column with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com