Ultrasonic roll welding device

An ultrasonic and seam welding technology, used in welding equipment, non-electric welding equipment, fluids using vibration, etc., can solve the problems of insufficient edge sealing strength and inconvenient recycling, and achieve convenient operation, smooth and beautiful appearance, and convenient recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

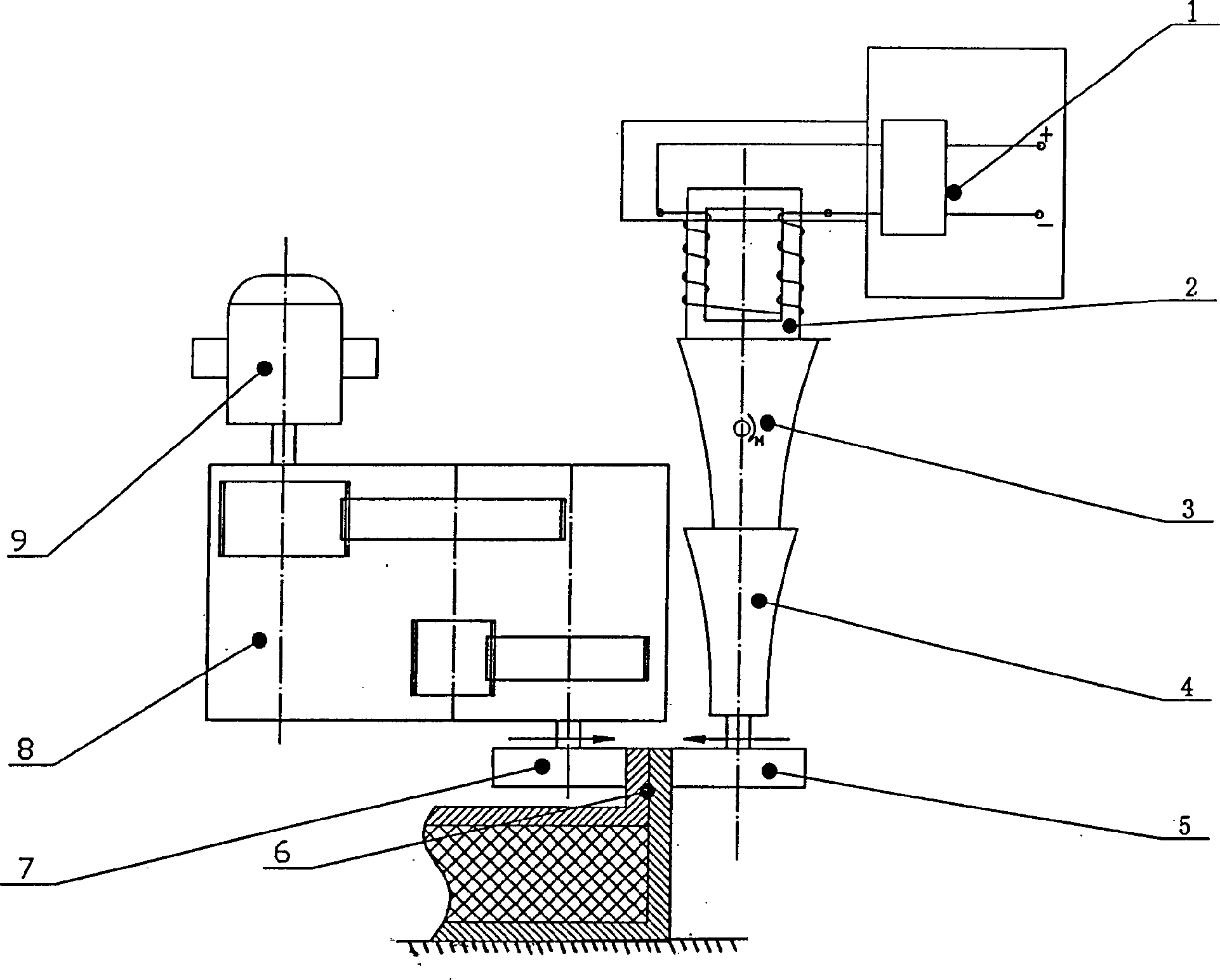

[0008] As shown in the drawings, it includes ultrasonic equipment consisting of ultrasonic generator 1, transducer 2, fixed rod 3 and horn 4, welding roller 5, reflector roller 7, reducer 8, servo motor 9; ultrasonic equipment A section of shaft extends from the end of the horn 4 to rotate and cooperate with the welding roller 5, the output shaft of the servo motor 9 is connected to the input end of the reducer 8, and the output end of the reducer 8 is in interference fit with the reflector roller 7; the workpiece 6 is placed on the working On the stage, the reflector roller 7 and the welding roller 5 press the flanging of the workpiece 6.

[0009] In the accompanying drawings, the alternating current is connected to the ultrasonic generator 1, and the ultrasonic generator 1 converts the alternating signal into an ultrasonic signal. The ultrasonic generator 1 is connected to the transducer 2, and the ultrasonic signal is transmitted to the transducer 2, and the transducer 2 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com