Guarding system for railway steel bridge deck and construction process thereof

A technology of protection system and construction technology, applied in the direction of coating, polyurea/polyurethane coating, etc., can solve the problems of foaming, affecting the anti-rust effect, unstable quality of epoxy zinc-rich anti-rust paint, etc., and achieve high efficiency, The effect of high construction efficiency and excellent construction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

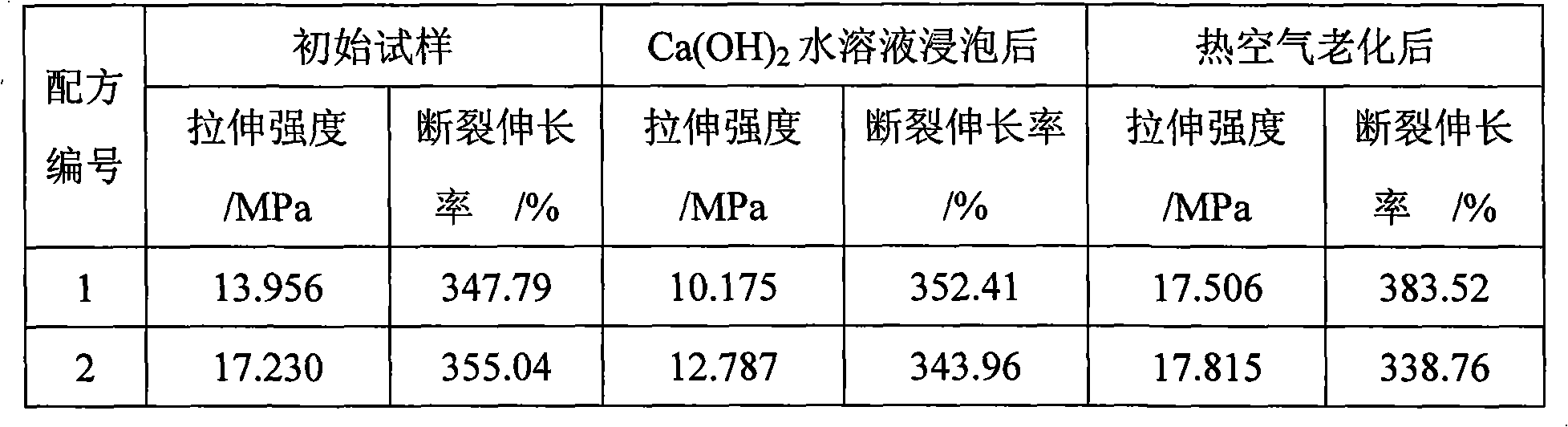

[0038] 1. Configure A component and B component of epoxy zinc-rich material and A material and B material of polyurea elastomer respectively:

[0039] The formula of component A is calculated by weight percentage: epoxy resin 6-10%, organic bentonite 0.2-1%, zinc powder 62.3-80.4%, additive 0.2-1.2%, anti-rust pigment A 1.2-2.3%, anti-rust pigment B1.5~2.6%, solvent 10.5~20.6%;

[0040] The formula of component B is calculated by weight percentage: 115 curing agent 20.7-50.3%, 650 curing agent 30.5-60.8%, solvent 18.5-28.5%;

[0041] The formula of material A is calculated by weight percentage: 90%-100% of semi-prepolymer, 0-10% of diluent; among them, the semi-prepolymer can be selected from 9480 and 9484 brands produced by Huntsman Company of the United States or C5051 and C5051 produced by Basf Company grades of semi-prepolymers.

[0042] The formula of material B is calculated by weight percentage: 42% to 67% of difunctional amino-terminated polyether, 11% to 27% of trif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com