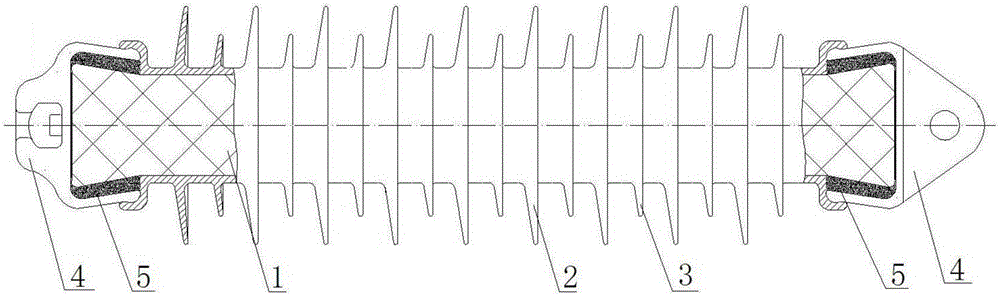

Rod-shaped suspension type composite insulator for railway and fabrication method of composite insulator

A ceramic composite insulator, rod-shaped suspension technology, applied in the direction of suspension/strain insulator, insulator, circuit, etc., can solve the problems of affecting driving safety, small creepage distance, short electrical clearance, etc., to increase creepage distance, The effect of increasing creepage distance and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

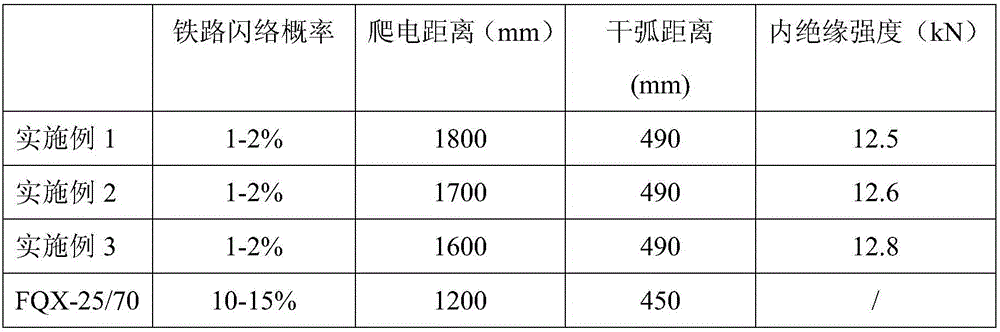

Embodiment 1

[0027] A method for manufacturing a rod-shaped suspension porcelain composite insulator for railways, comprising the following steps:

[0028] (1) Preparation of the porcelain rod insulator body: first prepare the base material of the porcelain rod insulator body, then add water with a total weight of 30% of the base material to the base material to obtain a slurry, ball mill the slurry for 12 hours to obtain a new slurry, and then After the new slurry is sieved and iron removed, the mud is squeezed, and the obtained mud cake is extruded in a vacuum mud refiner, and the extruded mud section is then dried by electric shade, and finally shaped and dried to obtain a green body. Glaze, sand, and fire to obtain a porcelain rod insulator body; the base material of the porcelain rod insulator body includes the following components, and the parts by weight of each component are: 5 parts of clay, 40 parts of industrial alumina, camphor 8 parts of village soil, 13 parts of Jingyang soil...

Embodiment 2

[0034] It is basically the same as Example 1, except that the base material of the porcelain rod insulator body includes the following components, and the parts by weight of each component are: 6 parts of clay, 45 parts of industrial alumina, Zhangcun soil 5 parts, 7 parts of Jingyang soil, 5 parts of Zuoyun soil, 16 parts of Qingcaoling, 20 parts of white clay, 15 parts of feldspar, 1 part of Ninghai soil, 6 parts of Xinhui soil; Portland cement glue includes the following parts by weight Components: 4 parts of superfine silica fume powder with a particle size of 0.2 μm, 52 parts of cement, 22 parts of quartz sand, 3 parts of mica powder, 3 parts of Simon600 early-strength and fast-setting polycarboxylate superplasticizer, 13 parts of water Parts; in step (3), spray silane coupling agent on the surface of the semi-finished product, and then heat it in an oven with a temperature of 40 ° C; in step (4), after the high-temperature vulcanized silicone rubber fills the mold cavity ...

Embodiment 3

[0037] It is basically the same as Example 1, except that the base material of the porcelain rod insulator body includes the following components, and the parts by weight of each component are: 3 parts of clay, 35 parts of industrial alumina, Zhangcun soil 12 parts, 20 parts of Jingyang soil, 15 parts of Zuoyun soil, 7 parts of Qingcaoling, 11 parts of white clay, 5 parts of feldspar, 6 parts of Ninghai soil, 1 part of Xinhui soil; Portland cement glue includes the following weight parts Components: 6 parts of superfine silica fume powder with a particle size of 0.3 μm, 45 parts of cement, 25 parts of quartz sand, 1 part of mica powder, 2 parts of Simon600 early-strength and fast-setting polycarboxylate superplasticizer, 10 parts of water part; in step (3), spray silane coupling agent on the surface of the semi-finished product, and then heat it in an oven with a temperature of 60 ° C; in step (4), after the silicone rubber fills the mold cavity space, it is heated at 180 ° C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com