A long-lasting antifouling flashover coating

An antifouling flashover coating, long-term technology, applied in antifouling/underwater coatings, fireproof coatings, coatings, etc., can solve the problems of reducing worker's work intensity, reducing production costs, etc., to reduce flashover accidents and reduce production Cost, effect of simple dip coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

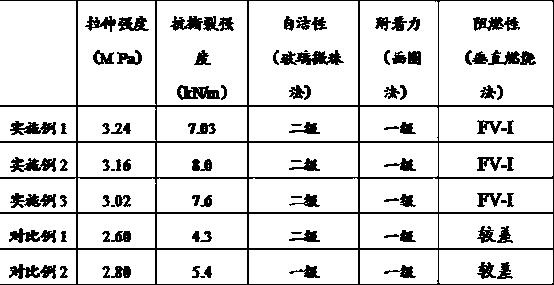

Examples

Embodiment 1

[0023] Add 11.25 parts of hydroxyl-terminated polydimethylsiloxane of 80000mpa.s, 18.75 parts of hydroxyl-terminated polydimethylsiloxane of 20000mpa.s, and hydroxyl-terminated polydimethylsiloxane of 5000mpa.s in a 500L kneader 12 parts of oxane, 7.5 parts of polydimethylsiloxane of 500mpa.s, 6 parts of fumed white carbon black, 4 parts of structure control agent, stir and heat up to 120 degrees, then add 6 parts of fumed white carbon black, aluminum hydroxide 30 parts, 4.5 parts of antifouling agent, raised to 155 degrees and stirred for one hour, then vacuumed (-0.04MPa) for 2 hours and then closed. After the temperature dropped, it was taken out and passed through the three-roll mill to obtain the base rubber.

[0024] Take 100 parts of the base glue obtained above, add 2 parts of oily iron red paste, 65 parts of diluent, 3.6 parts of dimethyl ketone oxime, 2.4 parts of vinyl tributylketoxime silane under the condition of blowing nitrogen, and stir for half an hour , and t...

Embodiment 2

[0026] Add 9.75 parts of hydroxyl-terminated polydimethylsiloxane of 80000mpa.s, 20.5 parts of hydroxyl-terminated polydimethylsiloxane of 20000mpa.s, and 5000mpa.s of hydroxyl-terminated polydimethylsiloxane in a 500L kneader 9.75 parts of alkane, 7.5 parts of polydimethylsiloxane of 500mpa.s, 5 parts of fumed white carbon black, 6 parts of structure control agent, stir and heat up to 120 degrees, then add another 5 parts of fumed white carbon black and aluminum hydroxide 28.75 parts, 7.75 parts of antifouling agent raised to 150 degrees and stirred for one hour, then vacuumed (-0.05MPa) for 2 hours and then closed. After the temperature dropped, it was taken out and passed through the three-roll mill to obtain the base rubber.

[0027] Add 100 parts of the obtained base glue to 1.5 parts of oily iron yellow slurry, 50 parts of diluent, 4.8 parts of dimethyl ketoxime, and 3.2 parts of vinyl tributyl ketoxime silane under the condition of blowing nitrogen, and stir for half an ...

Embodiment 3

[0029] Add 9.25 parts of hydroxyl-terminated polydimethylsiloxane of 80000mpa.s, 20 parts of hydroxyl-terminated polydimethylsiloxane of 20000mpa.s, and 5000mpa.s of hydroxyl-terminated polydimethylsiloxane in a 500L kneader 11.75 parts of alkane, 9 parts of polydimethylsiloxane of 500mpa.s, 9.5 parts of fumed silica, 6 parts of structure control agent, stirred and heated to 120 degrees, and then added 9.5 parts of fumed silica and aluminum hydroxide 27.5 parts and 7 parts of antifouling agent were raised to 150 degrees and stirred for one hour, then vacuumed (-0.06MPa) for 2 hours and then closed. After the temperature dropped, it was taken out and passed through the three-roll mill to obtain the base rubber.

[0030] Add 100 parts of the obtained base glue to 1.25 parts of oily carbon black slurry, 45 parts of diluent, 6 parts of dimethyl ketoxime, and 4 parts of vinyl tributyl ketoximosilane under the condition of blowing nitrogen, and stir for half an hour. Then add 2 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com