Overlap joint type structured airflow guide floor board

An airflow guiding and flooring technology, which is applied in the field of flooring, can solve the problems of increasing operating costs, reducing the ventilation area of ventilation floors, and increasing energy consumption of refrigeration equipment, and achieves the goal of reducing production costs, increasing matching applicability, and uniform distribution of air supply pressure Effect

Active Publication Date: 2012-10-03

SHANGHAI HUA YU ELECTRON ENG

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, in the application of the computer room, only the ventilated floor with a lower opening ratio can be used to ensure the load-bearing requirements of the computer room, which greatly reduces the ventilation area of the ventilated floor, resulting in an increase in the energy consumption of the refrigeration equipment and the increase in operating costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

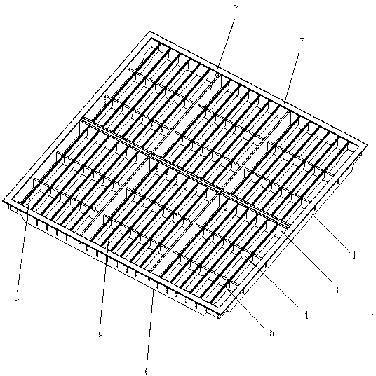

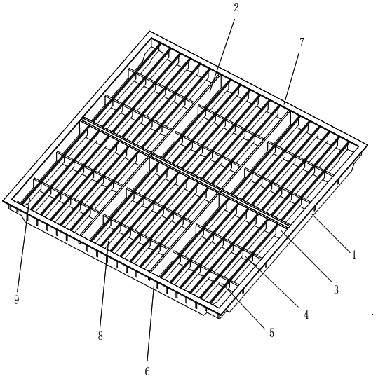

The invention discloses an overlap joint type structured airflow guide floor board, which comprises a first transverse beam, a second transverse beam, a first longitudinal beam, a second longitudinal beam, a third longitudinal beam, a fourth longitudinal beam, a panel, a first grating and a second grating, wherein the first transverse beam and the second transverse beam are parallel to each other; the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam are parallel to each other; the first transverse beam, the second transverse beam, the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam are vertically staggered; the panel is above the fourth longitudinal beam; and the first grating and the second grating are among the first transverse beam, the second transverse beam, the first longitudinal beam, the second longitudinal beam, the third longitudinal beam and the fourth longitudinal beam. According to the invention, by adopting the overlap joint type structure, the current problem that the opening rate and bearing contradict with each other is solved; and bearing also satisfies requirement of machine rooms in the event of increasing the opening rate.

Description

technical field [0001] The invention relates to a floor, in particular to an airflow guide floor with an overlapping structure. Background technique [0002] The computer room usually adopts the form of under-floor air supply to supply air and cool the servers and equipment in the computer room. The vents of the ventilation floor are generally set flush with the static floor, and the floor needs to be elevated. , The cold air enters the computer room through the vents on the ventilated floor, exchanges heat with the heat generated by the servers and equipment, and then is discharged from the air outlet on the upper part of the computer room. At present, the ventilated floor on the market is generally made of steel plate after stretching, punching, spot welding, and plastic spraying. The inner cavity is hollow to place the grid, and the surface is pasted with HPL melamine anti-static veneer or PVC anti-static veneer. The opening rate is generally small. , while not consider...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04F15/02F24F13/068

Inventor 孙杰莫儒明

Owner SHANGHAI HUA YU ELECTRON ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com