Packaging machine phase change mechanism

A packaging machine and transversal device technology, applied in packaging, paper product packaging, transportation and packaging, etc., can solve the problems affecting the packaging quality and appearance, low efficiency, waste of packaging bag materials, etc., to achieve good packaging quality, The appearance is flat and beautiful, and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

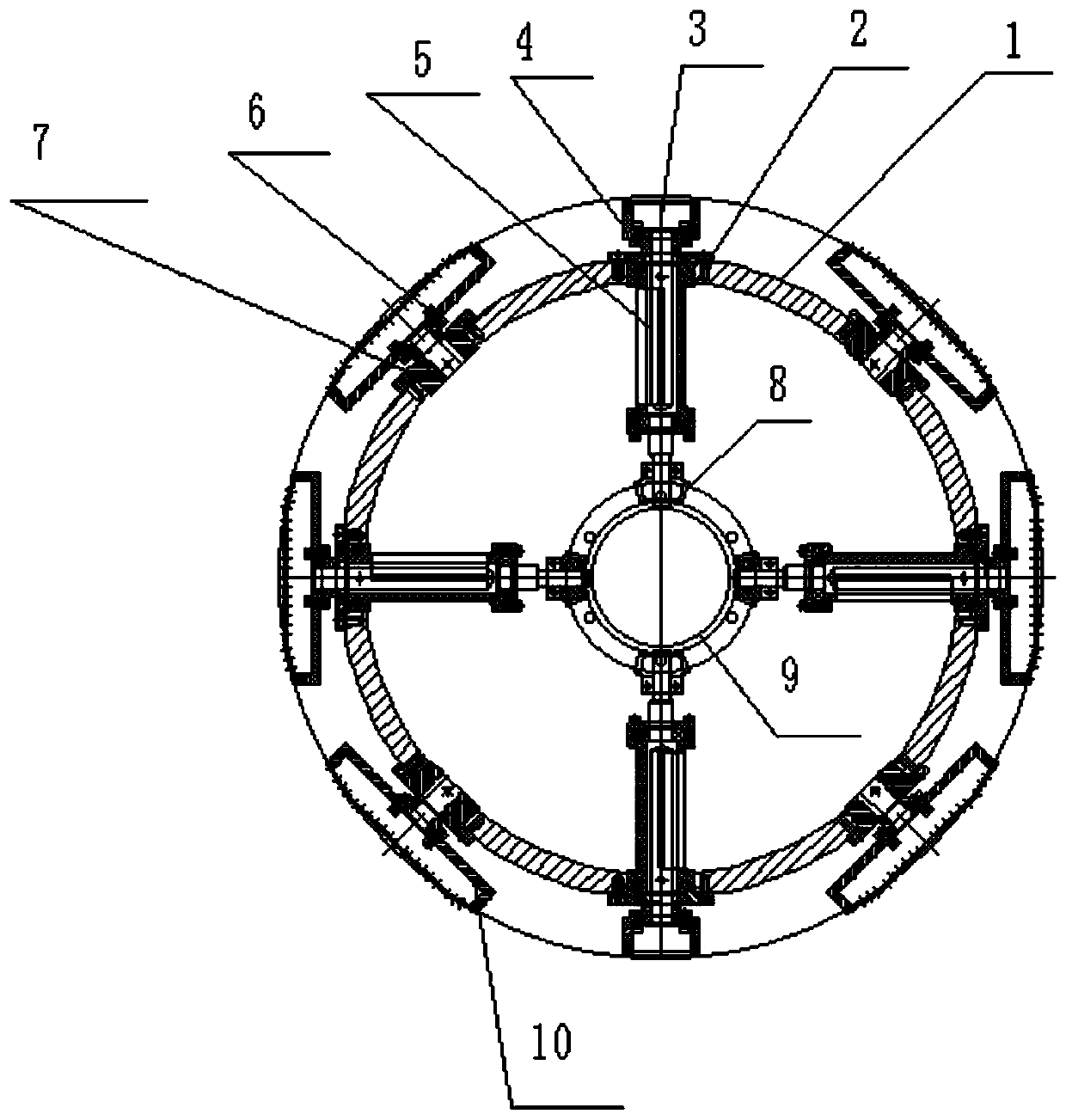

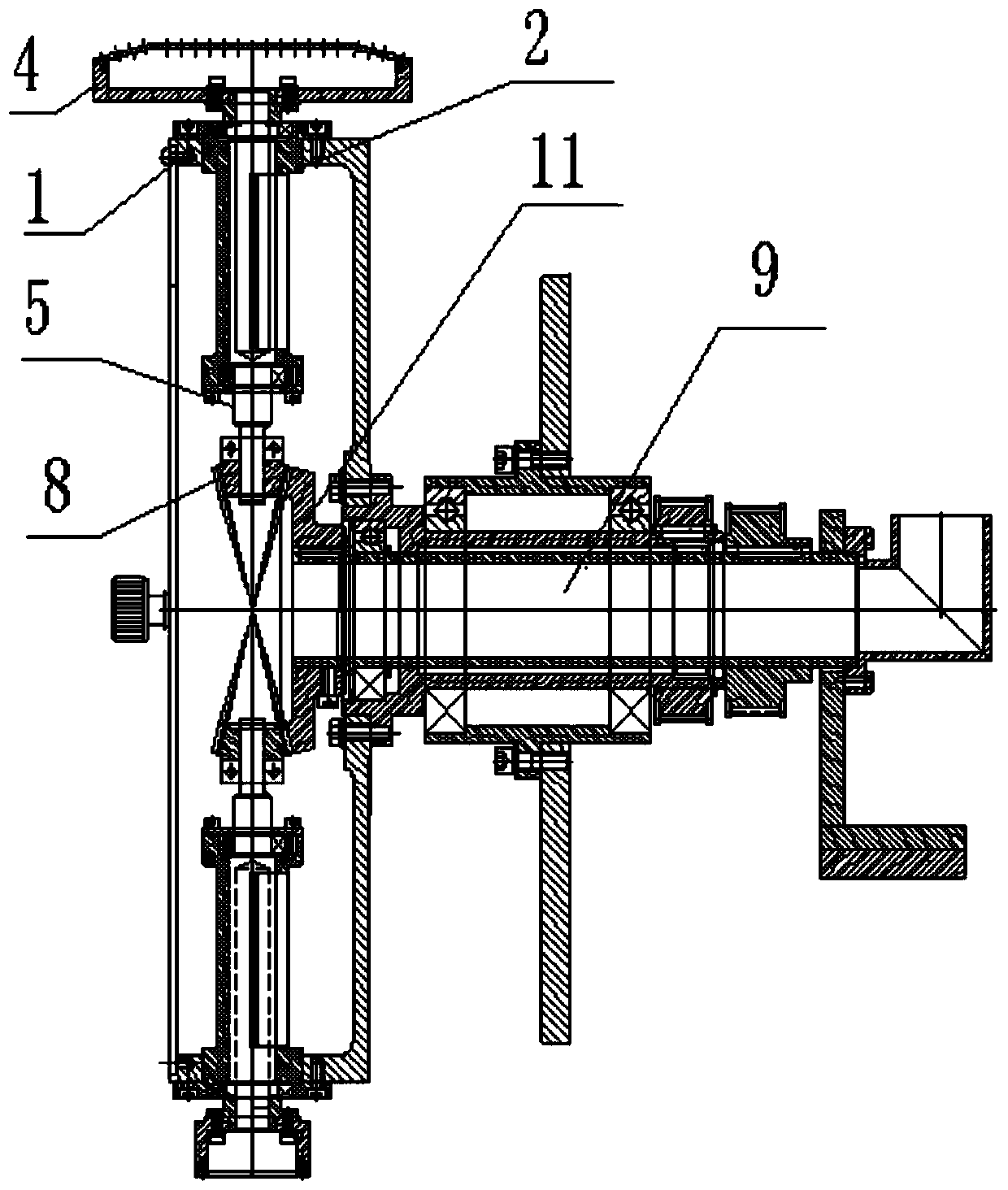

[0015] A phase-changing mechanism for a packaging machine, which includes a large flywheel 1, a common transversal device 6, and a flap-changing device 3, the common transversal device and the flap-changing device are four and arranged at uniform intervals along the large flywheel , the center of the large flywheel is equipped with a large flywheel rotating shaft 9, the rotating shaft of the large flywheel is driven by a motor (not shown) so as to drive the large flywheel to rotate, the ordinary horizontal changer is fixedly installed on the large flywheel, and the turning plate becomes horizontal The device is installed on the big flywheel and rotates while following the big flywheel to turn over the sanitary napkin packaging sheet.

[0016] Further, the flap-changing device includes a suction box 4 of the flap-changing device, a shaft sleeve 2 of the flap-changing device with bearings installed inside and a rotating shaft 5 of the flap-changing device, and the shaft of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com