Motor-drive type hot pressing and cold pressing formation clamp equipment of flexibly-packaged power lithium flexibly-packaged battery

A soft-pack battery, motor drive technology, applied in secondary battery manufacturing, non-aqueous electrolyte battery, electrolyte battery manufacturing and other directions, can solve the problems of long time, large area and low tooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

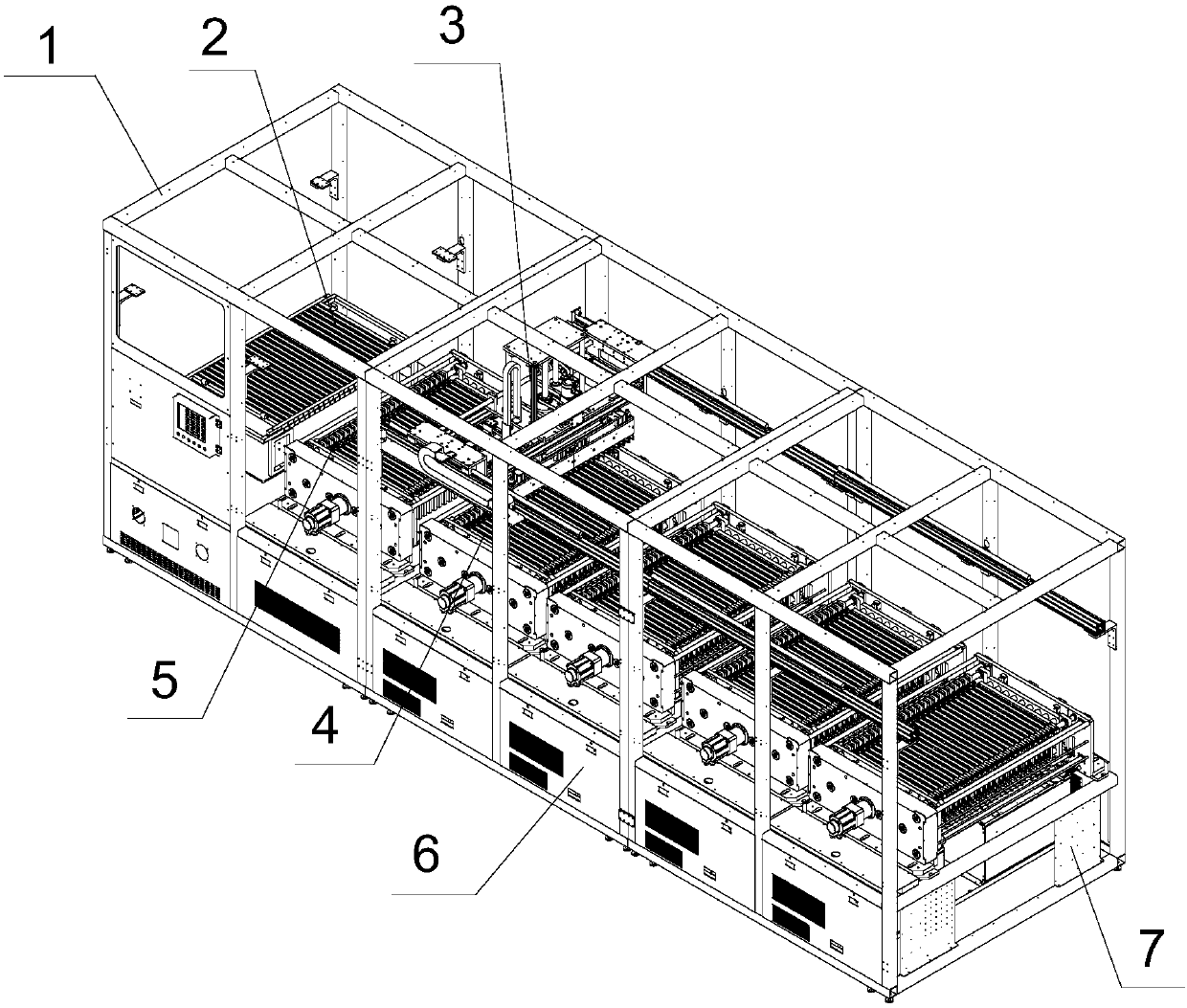

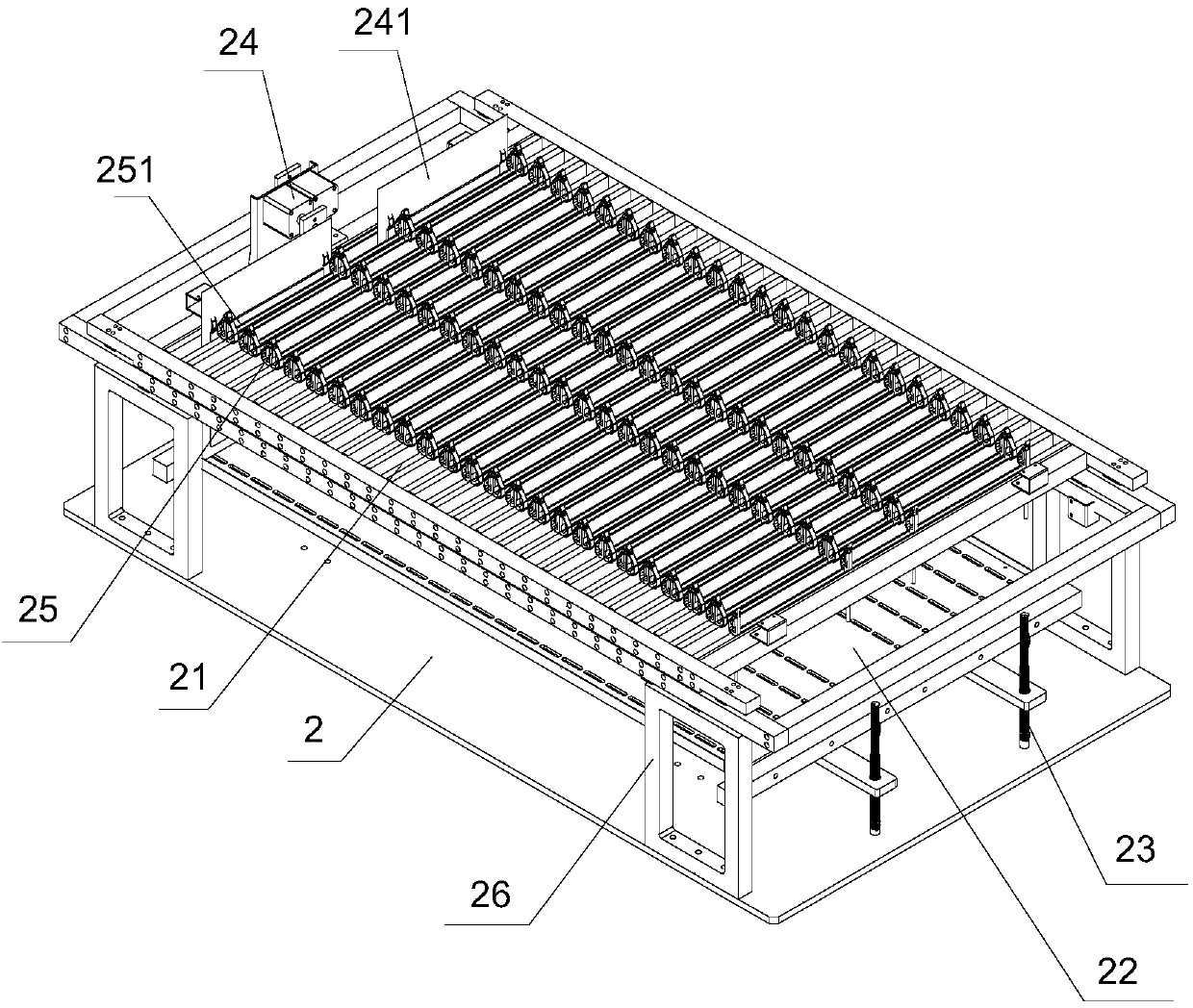

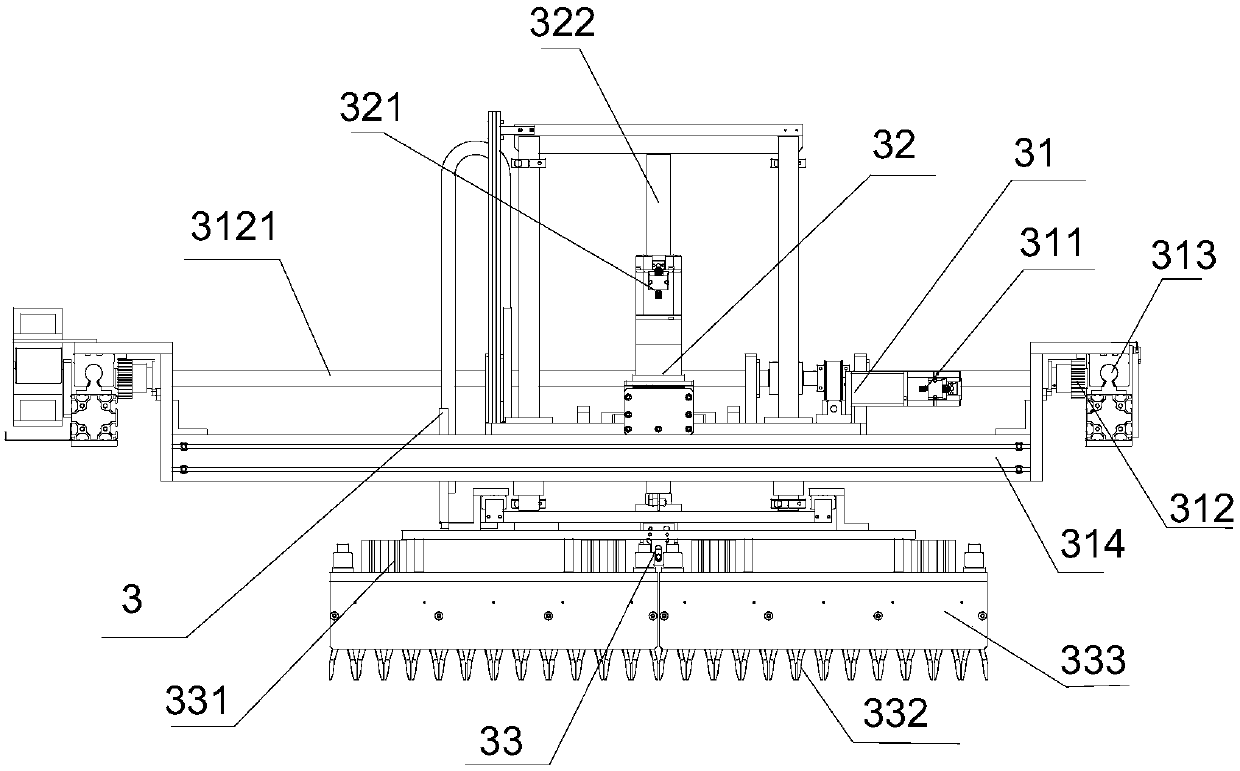

[0042] Embodiment 1 The soft-pack power lithium soft-pack battery motor-driven hot-cold pressing fixture equipment described in the present invention includes a frame 1, a feeding platform 2, a loading and unloading mechanical gripper 3, a cold-press forming fixture 5, and multiple sets Hot-press forming fixture 4, several charging and discharging power sources 6, safety alarm module and central controller 7, the feeding platform 2, cold-press forming fixture 5, and hot-press forming fixture 4 are arranged along the length direction of the frame in sequence In the middle layer of the frame 1, and the placement direction of the pouch battery of the feeding platform 2, the placement direction of the cold forming jig 5, and the placement direction of the battery of the hot pressing forming jig 4 are consistent, and are used for placing There is a one-to-one correspondence between the grids of the placed soft-pack batteries; the charging and discharging power supply 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com