Soft package lithium battery hot and cold pressed fixture formation automatic production line

A soft-pack lithium battery, automatic production line technology, applied in electrochemical generators, primary batteries, battery assembly machines, etc., can solve the problems of low production efficiency, large manual handling workload, and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

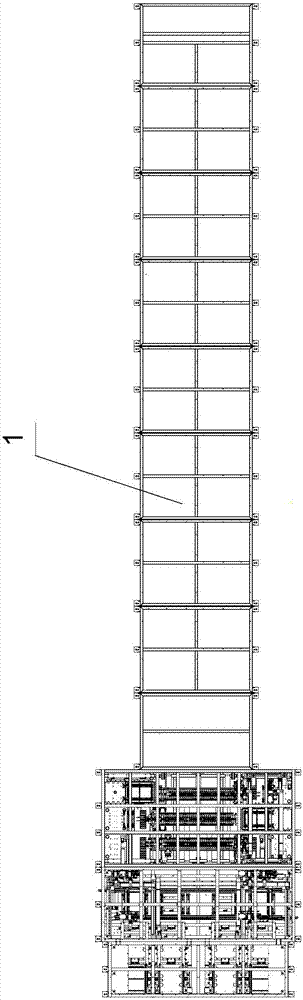

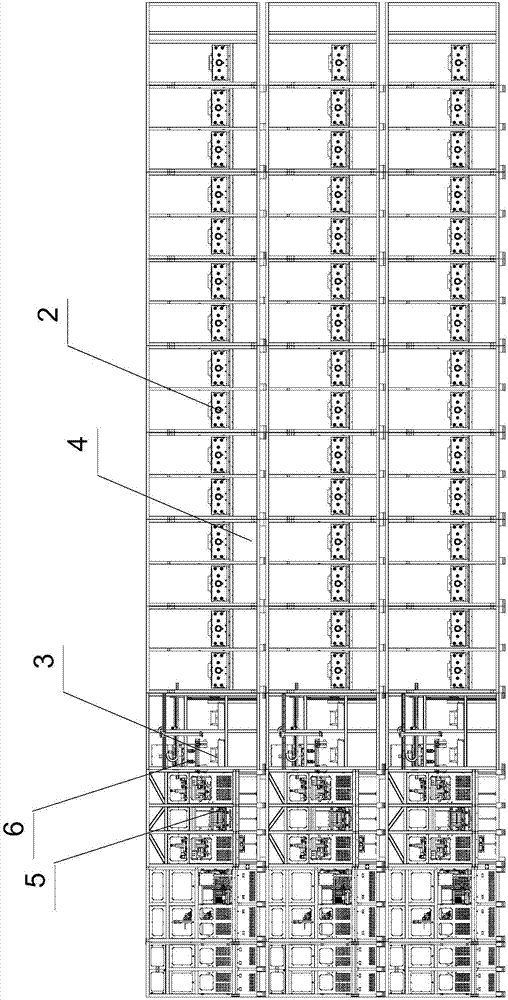

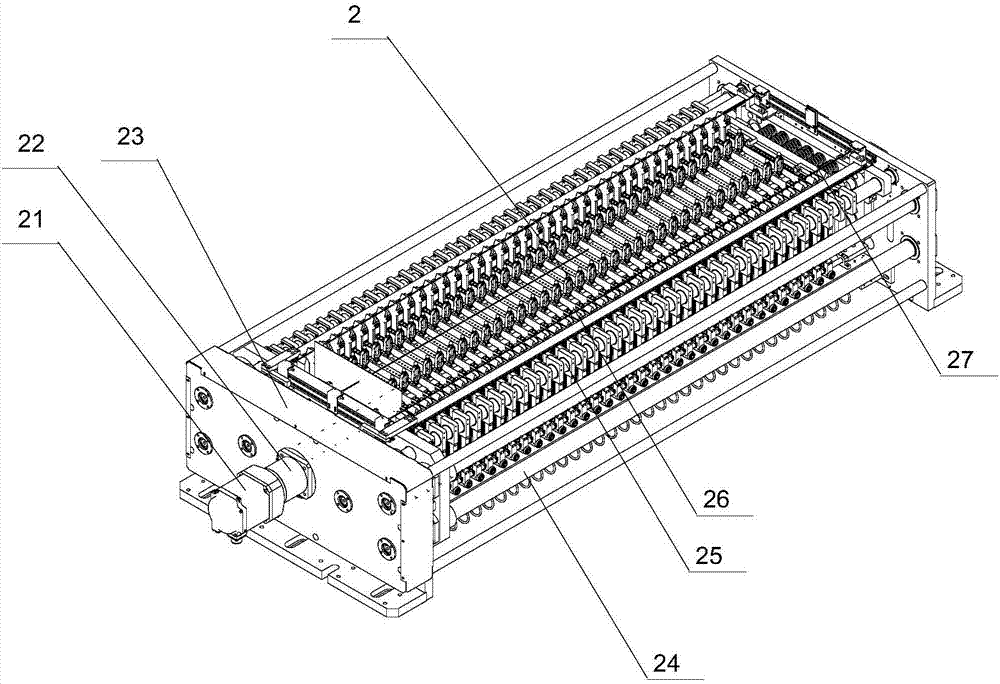

[0068] Embodiment 1 The automatic production line for the cold and hot pressing fixture formation of soft-pack lithium batteries according to the present invention is characterized in that it includes a frame 1, a hot pressing fixture forming unit 2, a cold pressing forming fixture unit 3, a charging and discharging forming control unit 4, Battery loading and unloading unit 5, transplanting manipulator unit 6, production process control detection unit, safety alarm unit and controller; one end of the frame 1 is provided with a processing station; The discharge formation control unit 4 is arranged on the surface of the frame 1 axially, and each set of hot press fixture formation unit 2 corresponds to a set of charge and discharge formation control unit 4; the cold press forming fixture unit 3, the battery up and down The material unit 5 and the transplanting manipulator unit 6 are arranged at the processing station of the frame 1, and the moving range of the transplanting manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com