Pole piece cutting and conveying device and lamination system

A conveying device and pole piece technology, applied in the directions of transportation and packaging, sending objects, pile separation, etc., can solve the problem of slow lamination speed, etc., and achieve the effect of small transfer process, high release position accuracy, and high lamination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

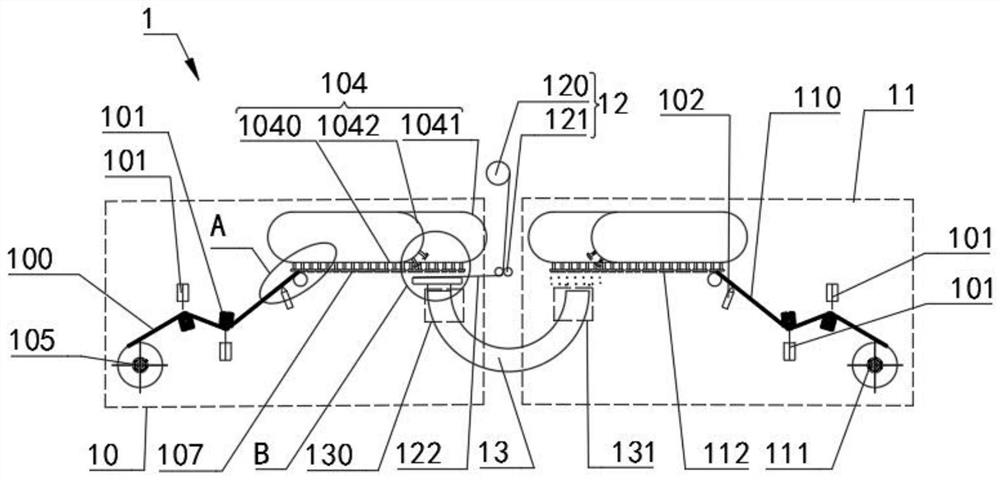

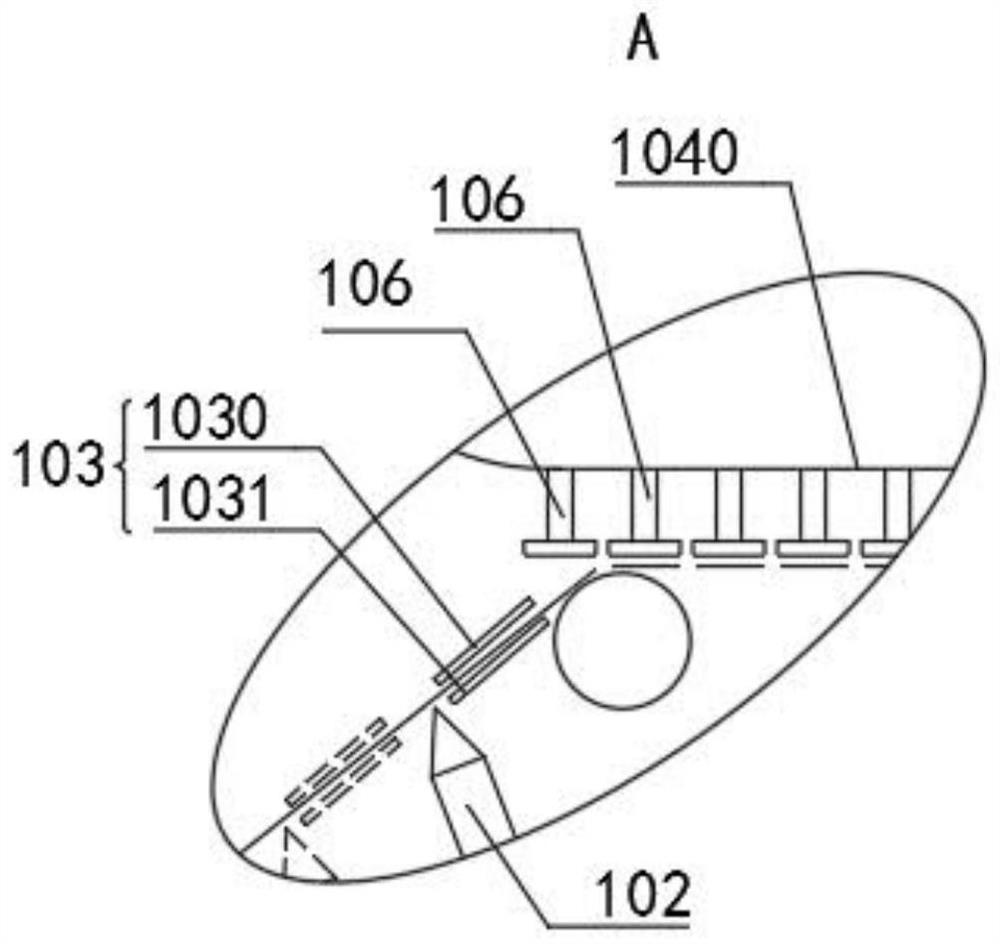

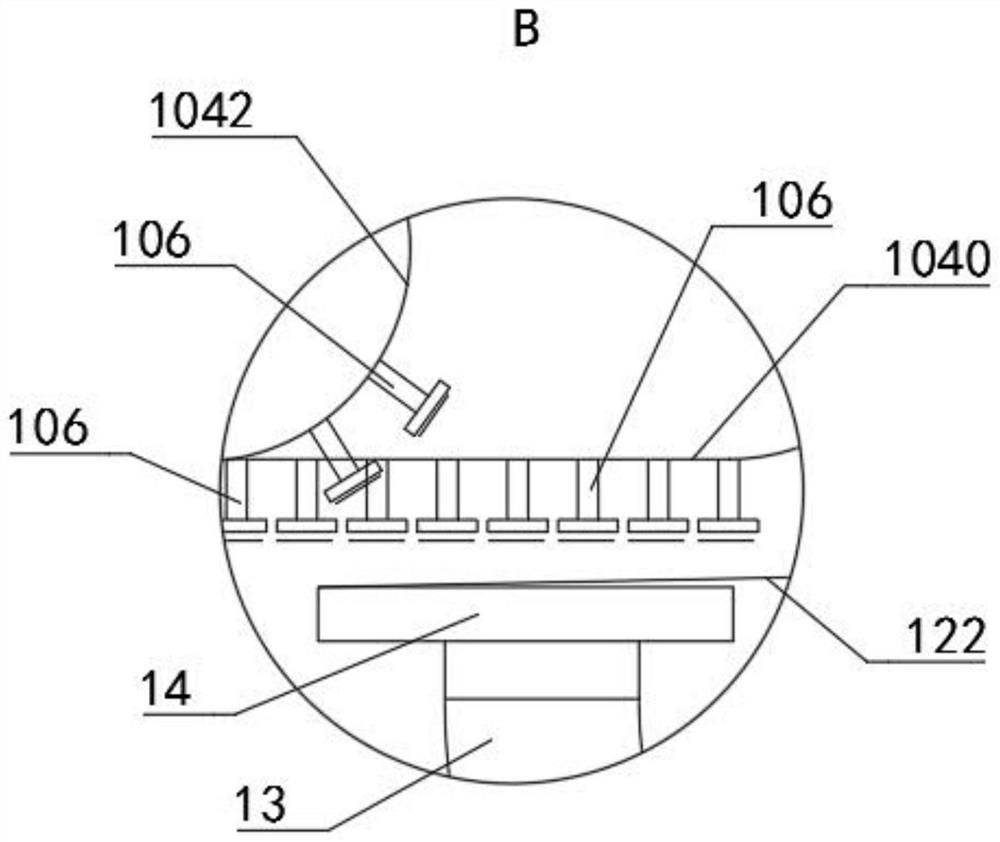

[0048] combine Figure 1 to Figure 4 As shown, the embodiment of the present application provides a pole piece cutting and conveying device including a pole piece unwinding mechanism, a pole piece cutting mechanism and a pole piece transportation mechanism arranged in sequence, wherein the so-called sequential arrangement means along The unwinding direction, that is, the direction in which the pole piece strips are delivered, is set sequentially, so that the pole piece strips released by the pole piece unwinding mechanism are successively delivered to the pole piece cutting mechanism and the pole piece transport mechanism.

[0049] The pole piece cutting mechanism is used to cut the pole piece material tape released by the pole piece unwinding mechanism to obtain pole pieces. Wherein, the pole piece unwinding mechanism can adopt the existing equipment with the pole piece unwinding function, for example, the pole piece unwinding mechanism includes a discharge roller and a drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com