Battery gluing machine

A gluing machine and battery technology, applied to primary batteries, battery assembly machines, primary battery manufacturing equipment, etc., can solve the problems of low production efficiency of manual gluing paper, unsatisfactory quality of gluing, poor consistency of gluing paper, etc. problems, to achieve the effect of smooth and stable gluing process, saving labor costs, and standard gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

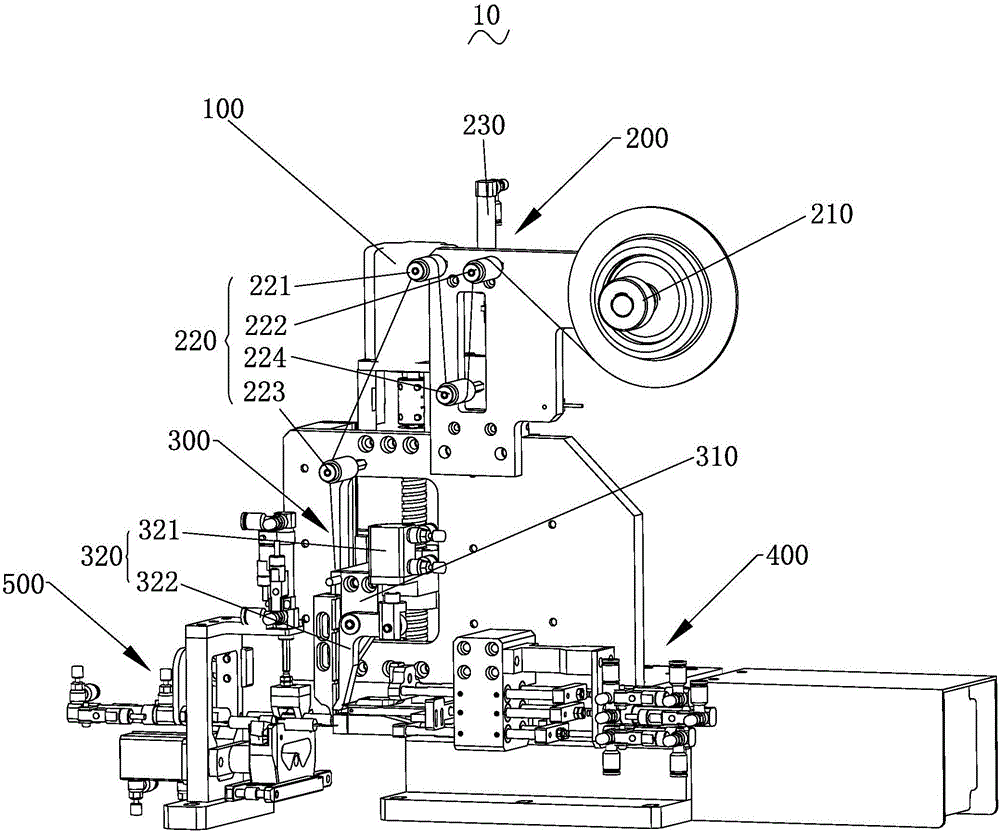

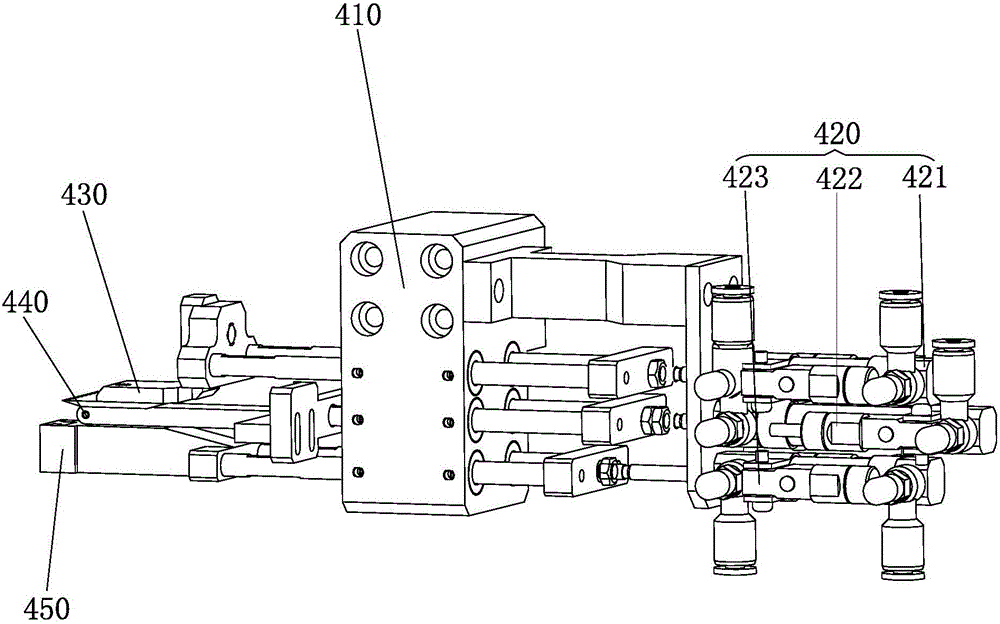

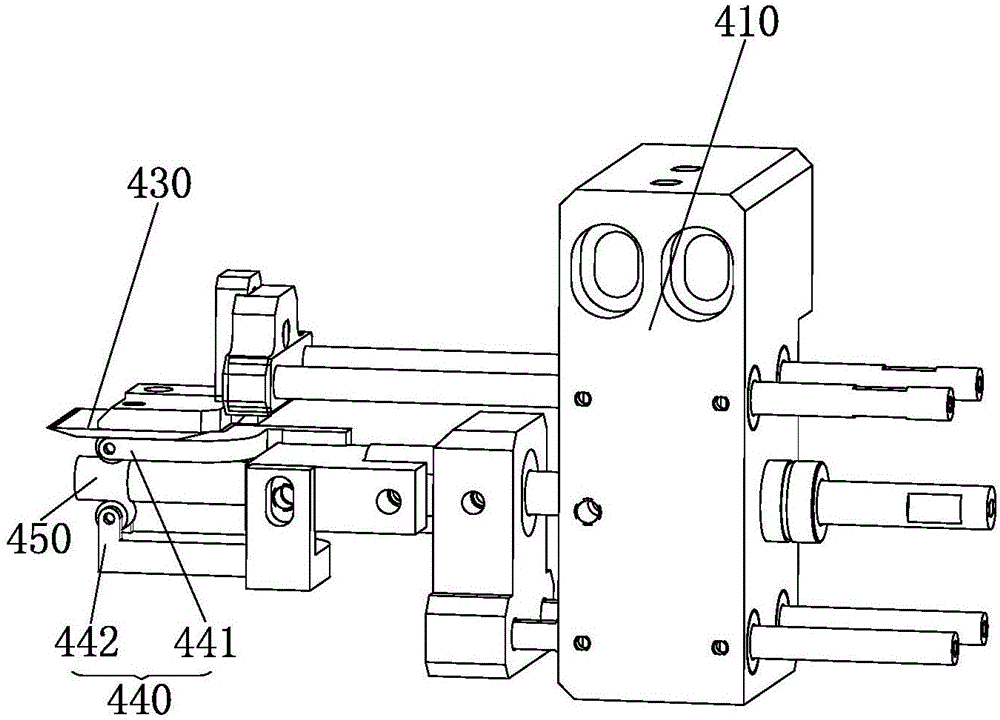

[0027] Such as figure 1 Shown is a structural diagram of a battery gluer 10 according to an embodiment of the present invention. A battery gluing machine 10, comprising: a frame 100, a tape feeding device 200 sequentially arranged on the frame 100, a tape conveying device 300 and a tape pasting device 400, and the frame 100 is also provided with a A battery placement device 500 for placing batteries.

[0028] The adhesive tape feeding device 200 includes: an adhesive tape placement wheel 210, an adhesive tape transmission roller group 220 and an adhesive tape transmission lifting cylinder 230. The adhesive tape transmission roller group 220 has a first fixed roller 221, a second fixed roller 222, and a third fixed roller. The roller 223 and the tape transmission liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com