Method for preparing thin single cell thermal battery in laminated mode based on molten salt thermal spraying technology and thin single cell thermal battery

A thermal battery and thermal spraying technology, which is applied in the manufacturing of primary battery equipment, primary battery, spray manufacturing, etc., can solve the problems of difficult forming of thermal battery pole pieces, inability to miniaturize, etc., so as to avoid the increase of battery internal resistance and improve stability. The effect of sex and simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

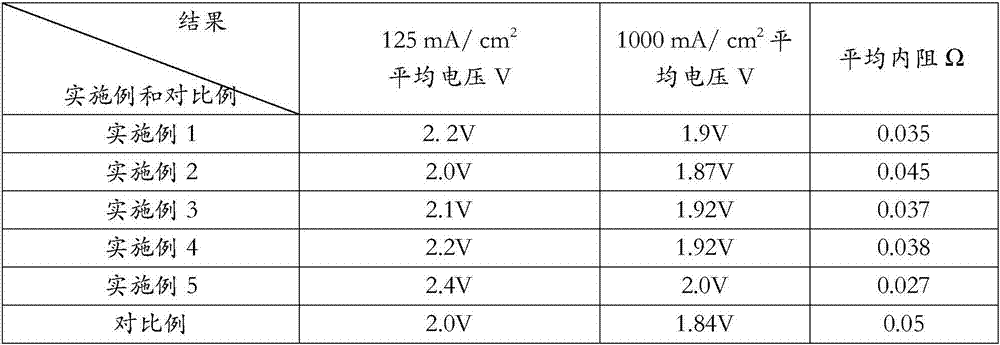

Examples

Embodiment 1

[0034] The method for laminating and preparing a thin single thermal battery based on molten salt thermal spraying technology in this embodiment includes the following steps:

[0035] Preparation of hot battery positive electrode molten salt: FeS with mass percentage 2 85%, KCl-LiCl binary electrolyte 14%, 1% Li 2 O peak cutting agent, mixed evenly, stirred and heated in a vacuum spraying equipment furnace to 400°C to melt to form a positive electrode molten salt.

[0036] Preparation of hot battery electrolyte molten salt: Mix KCl-LiCl binary electrolyte 50% and 50% MgO evenly in mass percentage, stir and heat in a vacuum spraying equipment furnace to 400°C to melt to form electrolyte molten salt. MgO is a binder, which can prevent the electrolyte molten salt from overflowing and cause a short circuit, and make the hot battery electrolyte more uniform.

[0037] Preparation of molten salt for negative electrode of thermal battery: Mix Li-Si alloy Li-Si 80% by mass and KCl-L...

Embodiment 2

[0041] The method for laminating and preparing a thin single thermal battery based on molten salt thermal spraying technology in this embodiment includes the following steps:

[0042] Preparation of hot battery cathode molten salt: the mass percentage of CoS 2 88%, LiCl-LiBr-LiF ternary all-lithium electrolyte 10%, 2% Li 2 O peak cutting agent, mixed evenly, stirred and heated in a vacuum spraying equipment furnace to 480°C to melt to form a positive electrode molten salt.

[0043] Preparation of hot battery electrolyte molten salt: Mix LiCl-LiBr-LiF ternary all-lithium electrolyte 60% and 40% MgO evenly in mass percentage, stir and heat in a vacuum spraying equipment furnace to 480°C to melt to form electrolyte molten salt.

[0044] Preparation of hot battery negative electrode molten salt: Mix 80% of lithium aluminum alloy Li-Al and 20% of LiCl-LiBr-LiF ternary all-lithium electrolyte evenly, stir and heat in a vacuum spraying equipment furnace to 480°C to melt, A negativ...

Embodiment 3

[0048] The method for laminating and preparing a thin single thermal battery based on molten salt thermal spraying technology in this embodiment includes the following steps:

[0049] Preparation of hot battery positive electrode molten salt: FeCoS with mass percentage 2 88%, LiCl-LiBr-KBr ternary low-melting point electrolyte 10%, 2% CaSi peak clipping agent, mixed evenly, stirred and heated in a vacuum spraying equipment furnace to 380°C to melt to form a positive electrode molten salt.

[0050] Preparation of hot battery electrolyte molten salt: Mix LiCl-LiBr-KBr ternary low-melting point electrolyte 40% and 60% MgO evenly in mass percentage, stir and heat in a vacuum spraying equipment furnace to 380°C to melt to form electrolyte molten salt.

[0051] Preparation of the negative electrode of the thermal battery: punching a 0.2 mm thick lithium-boron alloy into a disc to obtain a lithium-boron alloy negative electrode sheet. Lithium-boron alloy negative electrodes can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com